Blog Reducing Waste and Increasing Yield with Smart Press Brake Programming

Old press brakes and manual workflows make that difficult. Scrap, long setup times, and programming mistakes reduce throughput and eat into margins. To stay competitive, manufacturers need systems that are accurate, efficient, and easy to run.

Modern press brakes, especially when paired with intelligent software make that possible. Advanced programming enables the efficient and intuitive development of cutting plans for laser machines as well as bending plans for press brakes. It also manages integrated parts and order data, giving manufacturers clear oversight of their production information.

Where Waste Happens in Press Brake Operations

Waste shows up in more than just material costs. Some of the most common pain points include:

- Scrap from trial-and-error bending or poorly cut blanks

- Lost time during setups and tool changeovers

- Manual errors from programming at the machine or using outdated tooling

These problems slow production and reduce capacity, especially when the press brake becomes the bottleneck in an otherwise efficient line.

Software: The Key to Smarter Bending and Cutting Plans

The right software allows teams to develop cutting and bending plans offline, simulating bending sequences and ensuring all steps are correctly planned before the part reaches the machine. Smart programming also integrates parts and order management so users maintain full visibility of their data throughout the process.

Some of the capabilities of programming include:

- Creating precise flat cutting patterns for laser cutting

- Developing accurate bending plans for press brakes

- Managing tooling requirements and bend sequences

- Organizing parts and orders to optimize workflow

This end-to-end capability reduces errors, streamlines production, and improves overall consistency.

Integrated Parts and Order Manager: Staying on Top of Your Data

A parts and order manager integrated into programming helps you keep track of every part and every order in real time, so you always know the status of your production queue.

With this feature, you can:

- Quickly access detailed information about each part in the system

- Manage multiple orders simultaneously without confusion

- Monitor progress from programming through to production

- Avoid data loss or miscommunication by keeping everything centralized

This kind of transparency helps shops respond faster to customer needs, reduce errors caused by missing information, and improve overall production planning.

Better Setup and Better Flow

Older machines often require skilled operators to manually clamp tools and adjust settings. That process takes time and slows down job changeovers. It also creates a dependency on experienced labor that’s increasingly hard to find.

Modern press brakes eliminate much of this friction. Hydraulic clamping systems let operators change tools with a button press. Graphical tool mapping shows exactly where each punch and die should go. And if something is out of place, the machine detects it and alerts the operator before bending begins.

This reduces downtime and allows shops to move from one job to the next without delays.

Reliable Results Without Guesswork

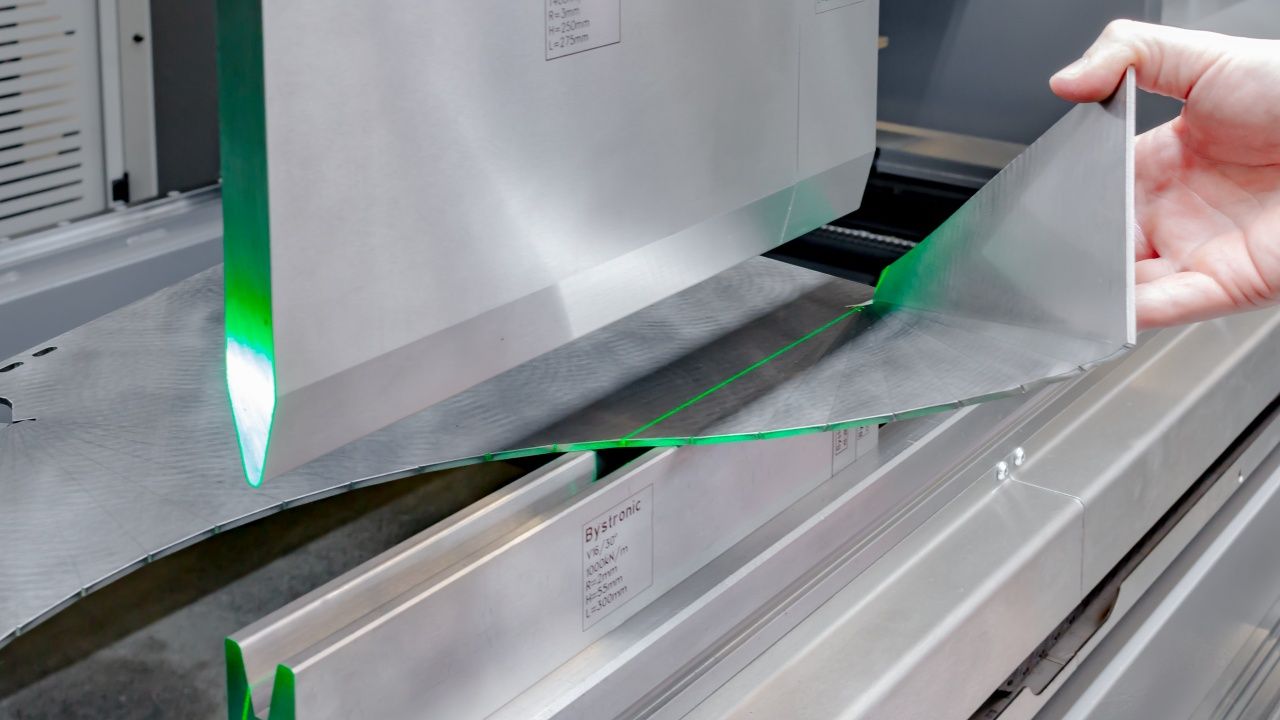

Modern bending doesn’t rely on high tonnage or outdated techniques. Air bending, combined with automatic compensation systems, gives more control with less force. Bystronic machines use features like:

- Dynamic crowning to keep bend angles consistent along the part

- Laser angle measurement to measure spring back in real time

- Automatic compensation for material thickness and grain variation

These features reduce the need for operator intervention and minimize the chance of bending defects. Shops can maintain accuracy even with inconsistent materials or mixed batches.

Make the Most of What You Have

Smart software helps shops get more from their existing tools, machines, and people. This includes:

- Sequencing jobs to reduce tool changeovers

- Simulating bends to avoid collisions and misalignments

- Scanning parts to automatically load the right program

- Integrating with third-party systems to fit within existing infrastructure

By planning ahead and eliminating repetitive setup tasks, shops can increase throughput without adding equipment or headcount.

Connecting the Workflow

Bystronic’s BySoft Software Suite connects programming, production, and data management into one streamlined workflow. It allows manufacturers to program cutting and bending operations accurately while keeping part and order data aligned throughout the entire process.

BySoft CAM Cut is built to integrate with machines from any manufacturer, which gives fabricators the flexibility to enhance their existing production systems without replacing current equipment.

BySoft CAM Cut & Bend ensure that cutting patterns and bending plans stay coordinated, and any adjustments on the floor can be made directly at the machine.

With BySoft CAM, shops can reduce waste, shorten setup times, and improve consistency across all operations. Whether using Bystronic machines or equipment from other brands, the result is a connected workflow that increases efficiency and delivers reliable results.

Contact Bystronic today to see how BySoft Software Suite can optimize your production environment and help you get more from your existing assets.