News The MES for sheet metal processing

Nowadays, people who want to reach their destination in the shortest possible time rely on a satellite navigation system. The software knows the shortest route. It tells the driver precisely when he will arrive at the defined destination. A satnav system is a valuable assistant when navigating complex traffic conditions. It maintains an overview, avoids detours, and immediately responds to changing conditions, such as short-term traffic congestion.

What if there were also such a satnav system for sheet metal processing companies? An intelligent software that helps manufacture and ship products with precisely defined costs and deadlines. An assistant that creates transparency and describes the ideal path, in order to guide sheet metal products through increasingly complex manufacturing environments.

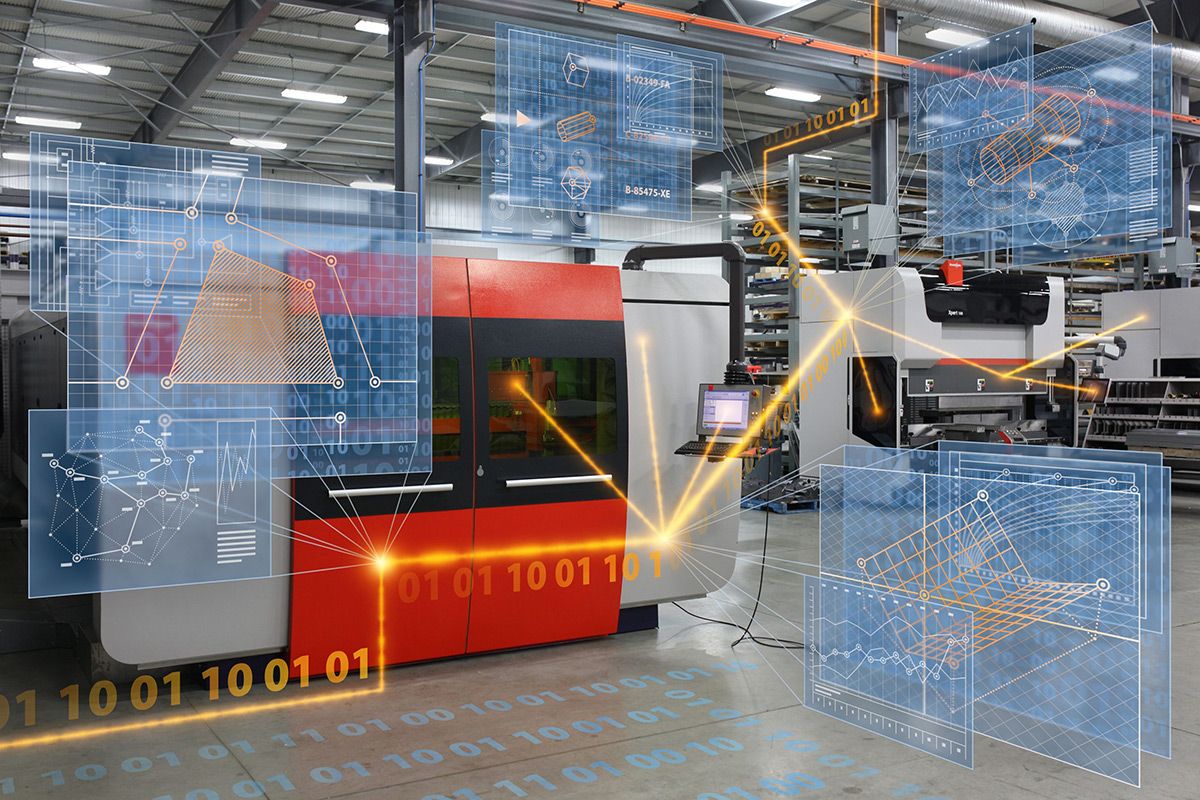

With the Bystronic MES, Bystronic is realizing precisely this vision. A manufacturing execution system (MES), which Bystronic is developing in collaboration with the Spanish software supplier Lantek. What makes the Bystronic MES so special is its consistent orientation towards sheet metal processing. With this system, Bystronic and Lantek are combining their expertise for machine tools and software design. The result will be an MES software solution that will allow users to digitally record and make optimal use of all the available resources on their shop floor.

The path through complex production

The Bystronic MES creates digital transparency across the entire added value chain of sheet metal products. In future, all the steps from the incoming order right through to the shipping of the completed product will be digitally recorded. This enables products to be manufactured according to defined costs and deadlines.

On the shop floor, the Bystronic MES allocates the created cutting plans to the resources of the available machines. The integrated Bystronic cutting systems provide fully automatic status messages about the start of cutting jobs, the remaining processing time, and the completion of jobs. This information flows via the Bystronic MES back to the user’s ERP system.

In future, thanks to the Bystronic MES, procurement and logistics will provide the required materials depending on the order situation and supply them “just in time”. This means that the materials arrive at the manufacturing stations in precisely the right amount and exactly when required for the current jobs. This makes the manufacturing processes leaner.

Ultimately, the end customers also benefit from the transparency and reliability of the Bystronic MES. They can always obtain precise information about the current manufacturing step of their products and by when they will be delivered.

After completion of the order, the manufacturing data is available for evaluation. The Bystronic MES will enable the controlling department to precisely calculate: Are the actual and target values relating to costs, times, and material within the defined limits? What rejects and idle times accrued at the individual manufacturing stations? All this information makes it possible to perform in-depth evaluations of the entire process chain and subsequently achieve sustainable optimizations.