News FABTECH 2018: Innovation Drives Success

The Future of High Performance Manufacturing

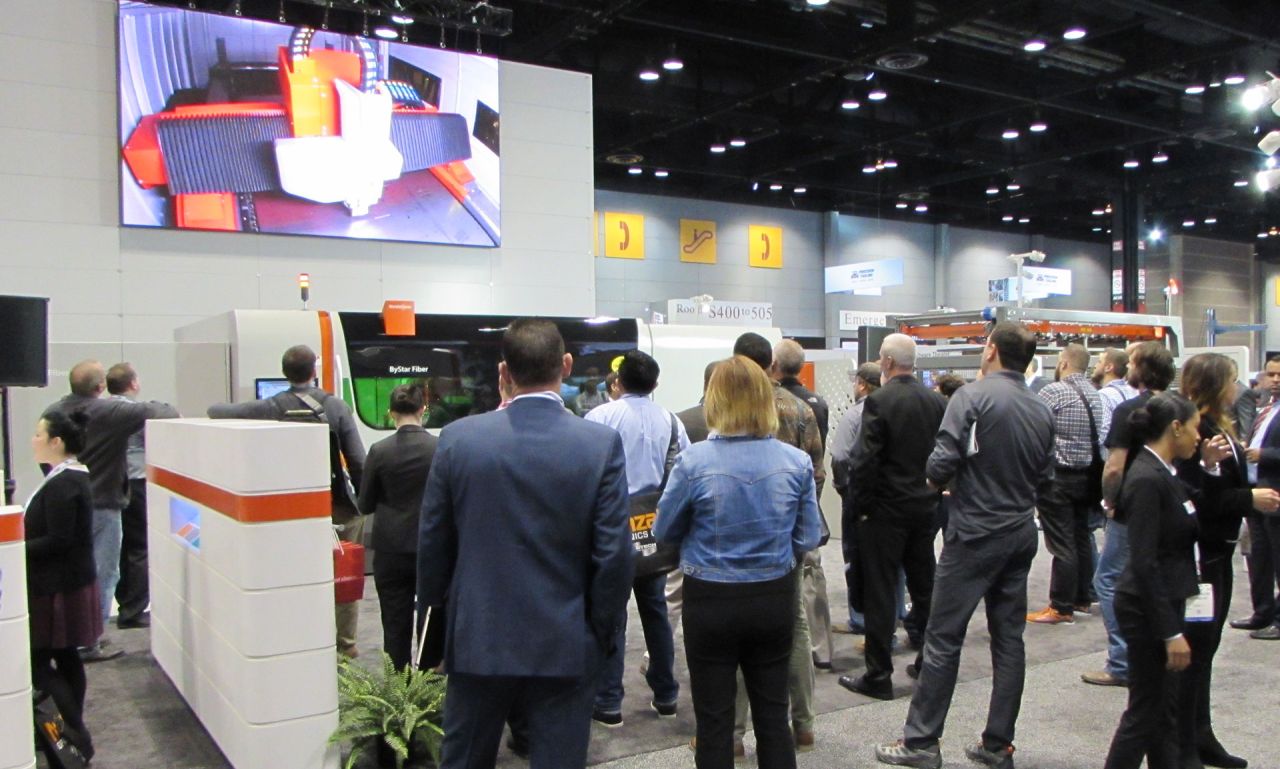

During FABTECH 2018 experience new and innovative high-performance solutions that cover the full spectrum of file-to-part manufacturing: laser cutting and bending machines, automation, and software technologies that are connecting and driving fabrication companies to new levels of productivity, profitability and success.

In manufacturing, rising above the status quo requires innovative machinery and innovative thinking. Innovation is the driver of high performance manufacturing and the key to competitive differentiation. Innovative thinking is at the core of Bystronic solutions. We recognize it’s not how a single piece of machinery will affect the fabrication process, but how all the machines and supporting software technologies work together to create a cohesive and effective fabrication solution. Bystronic will introduce the Next Generation Fiber Laser Platform equipped with the powerful ByVision Control and innovative features you have come to expect from Bystronic.

Built 100% for Fiber Laser Cutting: The ByStar Fiber with 10kW Fiber laser will be shown with the ByTrans Extended automated material loading/unloading system. Innovation is at the core of the ByStar Fiber laser. High machine dynamics and high process reliability ensure the highest parts output and premium cutting quality through a range of materials and sheet thicknesses.

Smart, Precise, Profitable and Easy-To-Use: The Xpert 150 press brake with revolutionary Bystronic ByVision Bending control, pressure reference technology, automatic dynamic crowning, and 6-axis back gauge system offer unmatched efficiency and productivity capabilities, and the highest repetition accuracy on the market. The Xpert 150 is the only press brake that introduces no angle errors itself with a ram positioning accuracy of .00015” inch.

Mobile Robot Meets High Speed Bending: The Xpert 40 with Mobile Bending Robot supports today’s fluctuating lot sizes and varying part complexities in a fully flexible automated or manual bending system. The robotic system can be set up when and where you need it in just a few minutes.

Modern sheet metal processing without high performance software is unimaginable today.

Make It Easy: Powerful BySoft CAM software represents a new generation of high performance design and manufacturing software tailored for high productivity, establishing an optimized manufacturing environment for the efficient scheduling and monitoring of manufacturing processes.

ByCockpit software monitors Overall Equipment Effectiveness (OEE) and provides managers with a tool for real-time measurement of machine performance and manufacturing efficiency, enabling companies to constantly improve their production. ByCockpit is accessible by web-enabled terminals such as desktops, notebooks, tablets and smartphones.

The Bystronic MES is a new software solution for production management that creates digital transparency across the entire process chain of sheet metal products. Users manage individual manufacturing steps according to defined timelines, and realize potential process improvement possibilities. What makes the Bystronic MES unique is the consistent orientation towards sheet metal processing.

Recent acquisitions expand the depth of Bystronic’s offerings: Bystronic has significantly expanded its existing portfolio of sheet metal fabricating technologies with new solutions for tube processing, automation and warehouse integration. At the Bystronic-Antil S.p.A. workstation, representatives will showcase the latest in automated solutions for sheet metal processing and warehouse integration. At the Bystronic-TTM S.p.A workstation, representatives will showcase their world-class systems for tube and profile processing.

Event: FABTECH 2018 (North America's Largest Metal Forming, Fabricating, Welding and Finishing Event)

Date: November 6-8 2018 (Tuesday – Thursday)

Location: Georgia World Congress Center, Atlanta, GA – BOOTH B7229