News Time Machines

For some, 2005 doesn’t seem that long ago, but when put into context, it can feel like ancient history. President George W. Bush was just entering his second term in office, the Patriots only had a few Super Bowls under their belt and YouTube was a brand-new, novel website. A lot has changed in 17 years.

For Todd Ludlow and his wife, Jenny, 2005 probably feels like a totally different era, too. They had just opened the doors to Ludlow Mfg., their new 1,500-sq.-ft. fabrication shop, which at the time was nothing more than a CO2 laser cutter, a metal saw and press brake, and a handful of staff. A lot has changed in 17 years at Ludlow Mfg., as well.

Since then, the company has outgrown its facility multiple times over, recently moving into its fourth building with 130,000 sq. ft. of manufacturing space. Within those walls, Ludlow Mfg. has a workforce of nearly 100 employees. Unsurprisingly, this growth didn’t happen organically.

“For 16 years straight, we invested in equipment – the best equipment we could get,” Ludlow says. “That entire time, we never went a year without acquiring new equipment, even in 2008, 2009 and 2020.”

Fully equipped

As soon as the doors were opened at Ludlow Mfg., future opportunities were in sight. Equipment investments started with an additional CO2 laser cutter and led to more press brakes and later multiple high-power fiber laser cutting systems. The company developed a complete machine shop with the acquisition of mills, lathes and Swiss screw machines, and as years passed, manual welding – both MIG and TIG – and seven robotic welding cells were added to the mix.

Over the years, Ludlow Mfg.’s collection of equipment has grown to the point where visitors might mistake the shop as a Bystronic Inc. showroom. The company has a fleet of Bystronic lasers and press brakes, which started back in 2007 with the purchase of a 4.4-kW BySpeed CO2 laser cutting system. No matter the make or model, however, all equipment will inevitably require service of some sort, which is why Ludlow landed on Bystronic as his chosen laser and press brake machine supplier.

“They all break; either you break them, or they break on their own,” he says. “Service, therefore, was a major focus when vetting equipment suppliers, and it was an overwhelming theme during almost every conversation I had with Bystronic’s customers. It was these conversations that really drove home the purchase of our first brand-new laser."

“We’d purchased pre-owned lasers in the past, but the BySpeed was our first brand-new laser,” he adds. “It ended up being a great investment and, ultimately, helped put us on the map from the competitive standpoint of having new equipment, new technology, faster cutting speeds and higher throughput.”

High-power success

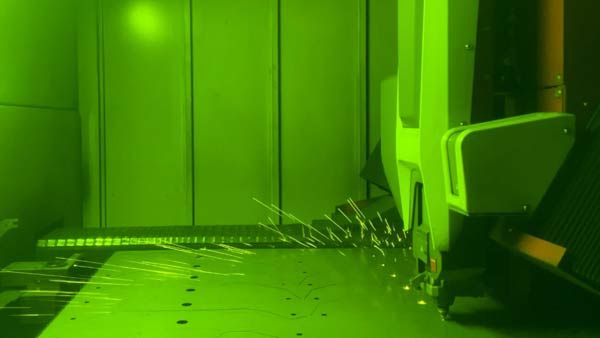

With the past as prologue, Ludlow Mfg.’s most recent investments are yet again putting the company on the map. At the beginning of 2021, a 15-kW ByStar fiber laser cutting system arrived, and then, shortly after Fabtech 2021 in Chicago, a 20-kW ByStar fiber laser was acquired – the first 20-kW Bystronic fiber laser installed in North America.

“We were in the position to replace our two older 6-kW CO2s, so we decided to purchase the 15-kW fiber laser, which was installed in the middle of 2021,” Ludlow says. “Later in the year, a contact from Bystronic called before Fabtech to let us know they were debuting a new 20-kW fiber laser. He asked if I would be interested in helping them demo it and based on the successes we’d had with the 15 kW, I was on board."

“When people ask me why I’m going with more power, my answer isn’t just about speed,” he explains. “The investment was also based on the superior cut edge quality the ByStar can deliver. When the parts come off of the laser, we don’t want to have to touch them again; our parts need to be burr-free. I think a lot of people become completely enamored with how fast it cuts, but there’s much more to it.”

Fabricators exploring the ultra-high-power fiber laser technology found in the 15-kW and 20-kW fiber lasers quickly discover what Ludlow now knows: the edge quality easily rivals that of CO2. Features such as the Bystronic BeamShaper and KerfScan ensure those high-quality edge results.

The speed of the lasers, however, can’t be denied. At Ludlow Mfg., a job that used to run for 50 min. on the company’s CO2 now runs in 9 min. on the new 15-kW fiber.

As a medium- to high-volume contract manufacturer, long runs are common at Ludlow Mfg., so the cutting speed of the 15-kW and 20-kW fiber is a major boon in those situations. The company has customers in lawn and garden, server cabinetry, electric vehicles, construction, agricultural, and recreational vehicles, and they are all benefitting from the quicker turnaround times.

Critical component

Early on, Ludlow recognized what quality equipment investments could do for the future of his business, but with the goal to run his equipment around the clock, he also recognized the need for automation. Manual loading and unloading wouldn’t suffice.

“Even at the beginning when we bought our first fiber laser, I knew it wouldn’t be worth it if it didn’t include automation,” he says. “From lasers and bending cells to robotic welding, whatever the investment, automation has always been a critical component for us.”

Keeping with the commitment to run lights out as often as possible, two tower systems from Bystronic are on order to be installed in November 2022 – one for the 15 kW, and one for the 20 kW. Two part sorting systems are also on order to be delivered in early 2023.

“After running the 15 kW for two months, we had material everywhere,” Ludlow says. “We had material stored in the warehouses and up and down the building. We could have put up a bunch of racking, but it wasn’t just about storing it. We also needed to retrieve it quickly to put it on the machine. Without that capability, the lasers work faster than we can feed them material.”

Leading up to the delivery of the two tower systems, Ludlow Mfg. is still reaping the benefits of the new ultra-high-power fiber laser cutting systems. As an example, the company recently processed a large volume of 5/8-in. plate in one week that previously would have taken three and a half weeks.

“Quite honestly, I couldn’t have turned it around as fast for the customer without the higher power and, of course, the automation that is offered with it,” Ludlow says.

Future potential

Considering Ludlow Mfg.’s deep experience with Bystronic controls and software, the only learning curve was dealing with how fast the lasers could process parts and then, of course, fully leveraging the new capabilities the technology offers. “The problem wasn’t dialing in the equipment to cut a part; it was dealing with how fast we process things,” he says.

“We’ve been cutting with fiber laser technology for more than 10 years now, and I have some really good employees that understand the machines and know what they’re doing,” he adds. “These ultra-high-power lasers are allowing us to learn and do a lot of things that we couldn’t do before. It’s a good problem to have.”

One of the new capabilities he’s referring to is the ability to cut through thicker materials faster. In the past, typical material thicknesses at Ludlow Mfg. ranged in the 20-gauge to 5/16th range; fast-forward to today and the lasers handily cut up to 1-in.-thick plate.

“We’re a lot more competitive now in the marketplace with thicker materials,” he says. “This is the stuff that we would struggle with in the past because it would take up too much of our capacity. Now, it’s no big deal. It’s opened the doors for us to go after new business.”

Ludlow says that, ultimately, the goal is to have 15-kW fiber as the lowest power machine on the shop floor. That way, he won’t have to worry about competing with anyone that only has 6-kW or 10-kW capabilities.

“If the economy slows down anytime in the future, I know with the 15-kW and 20-kW fiber lasers, you’re going to have to really challenge me for that work if you’re sitting on a 6 kW,” Ludlow concludes. “To be competitive, you have to keep updating to prepare for what’s around the corner. You just do.”

As published in Shop Floor Lasers magazine

By: Abbe Miller, editor-in-chief