News Tube laser processing: purchased potential

Laser processing of tubes and profiles offers unique design possibilities

Bystronic/TTM Laser's three production lines are housed in 8,00 square meters of a 55,000-square-meter facility–a building largely made up of tubes and pipes shaped using the company's laser cutting equipment. According to Bystronic, the factory itself demonstrates the technological potential of structural tube in markets such as architecture and construction, furniture design and automotive.

"Our machines open up new design possibilities, as designers benefit from the ability to create flexible contours and simple joins," Stefano Dal Lago, TTM's sales director, told Bystronic World magazine. Designers using this equipment can also reduce the need for welding and increase their accuracy on repetitive tasks, he added.

Based in Cazzago San Martin, Italy, Bystronic/TTM develops 2D and 3D laser systems for the cutting of tubes and profiles and welding of large-format metal sheets. Bystronic, headquartered in Niederoenz, Switzerland, began a partnership with TTM in November 2017, then purchased the company outright in March 2018. That decision was a result of increased customer requests for the ability to purchase all sheet metal fabrication technologies, including automation, warehouse integration and digital networking solutions, from a single source.

Family affair

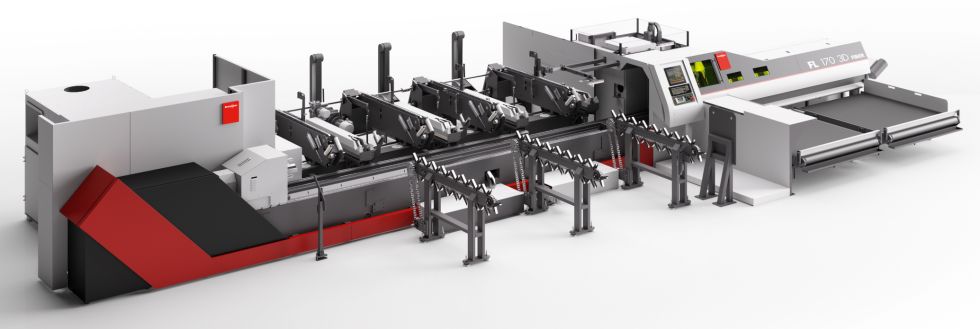

The availability of 2D and 3D laser cutting technology allows designers and fabricators to individually customize and precisely cut and bevel a wide variety of parts: tubes with round, square and rectangular shapes as well as diverse open profiles. As a result of the acquisition, Bystronic now offers a family of fiber and CO2 tube laser cutting systems that can handle diameters from 0.5 in. to 32 in. and pipe and profile lengths up to 50 ft. in carbon and stainless steels, aluminum and other nonferrous materials.The M2 series machine combines a fiber laser with 3D cutting capability, white the Mc and M4 series use CO2 technology. The M2 is designed for fabricators of OEMs that are processing tube and profile diameters between 0.5 in. and 6.6 in. and up to 28 ft. long. the lasers have flexible loading technology to ensure high-precision processing and intelligent unloading increases productivity and reduces downtime.Precision in-line measurement devices, like the LaserScan system, allow for realtime correction of errors in tubing stock, and weld seam detection cameras can orient a tube correctly for a downstream bending program so all parts will have the same result in a tube bender."The adoption of 3D cutting for tubes has been a game changer for fabricators looking to achieve the highest precision of parts," says Brendon DiVincenzo, product manager, Laser & Automation, for Bystronic. "While the investment may seem large, the increased throughput and the consistency of production can't be overlooked."

Creative parts

DiVincenzo says customers are excited by the lasers' ability to automate the entire part fabrication process. Parts that used to undergo multiple processes–sawing, drilling, grinding–have been "reduced to a single operation where a number of tubes is loaded into the machine and finished parts ready to be bent or welded are unloaded from the machine."The CAM software's capability to quickly recognize geometry and automatically apply cutting technology "breaks down a lot of the psychological barriers users might have regarding such a large step forward in technology," he says. "Wile it may seem like the laser is the master and controller of what is possible, the truth is that the programming workflows allow for much more control than was previously available."In addition to eliminated or consolidating multiple manufacturing operations, the laser tube-cutting equipment provides value-added operations, such as engraving or tab-and-slot geometry, that can shave additional time within an assembly process and lower error rates.

"While flat laser-cutting [machine] purchases tend to be focused on capacity and cost-per-part, tube lasers tend to be a capability-driven purchase," DiVincenzo says. And the flexible capabilities of next-generation tube lasers are beginning to revolutionize how designers think about parts."We have a customer that has one of the largest machines (up to 24 in/ diameter on an FL600 model) who is now able to offer some very large and very complicated structural I-beam components for the construction industry, where traditional methods of manufacturing them would have imposed significant limitations on the architecture of the structure," he says. "Now, the precision of the machine can be applied to a part that is over 20 ft. long, which makes for reduced assembly time on a construction site where tie and labor costs are highest."Ultimately, DiVincenzo continues, the technology is allowing fabricators to "create a stronger link between design, engineering and manufacturing. There are capabilities of the machines that can only be utilized if the parts are designed to leverage them. For example, an assembly that was originally comprised of multiple tubes could be cut with fold reliefs designed to allow it to be bent into a predefined structure by an operator and welded without going through a tube bender."Bystronic and TTM both work closely with customers "to show them the limitless possibilities of our laser tube cutting and profile cutting technologies."

As seen in FF Journal, Tube & Pipe, May 2019 Issueby Lauren Duensing, Contributing Editor