News Experience “Innovation - The Driver of High Performance Manufacturing”

During Fabtech 2016 Bystronic will showcase its line of innovative high performance manufacturing solutions that covers the full spectrum of file to part manufacturing, including automated programming, high performance fiber laser cutting, automation, and metal bending. In addition, Bystronic’s ByFinances offers highly competitive and innovative financing options that make owning a Bystronic a reality.

Ongoing machinery and software demonstration will be held at our booth C35069 throughout the show.

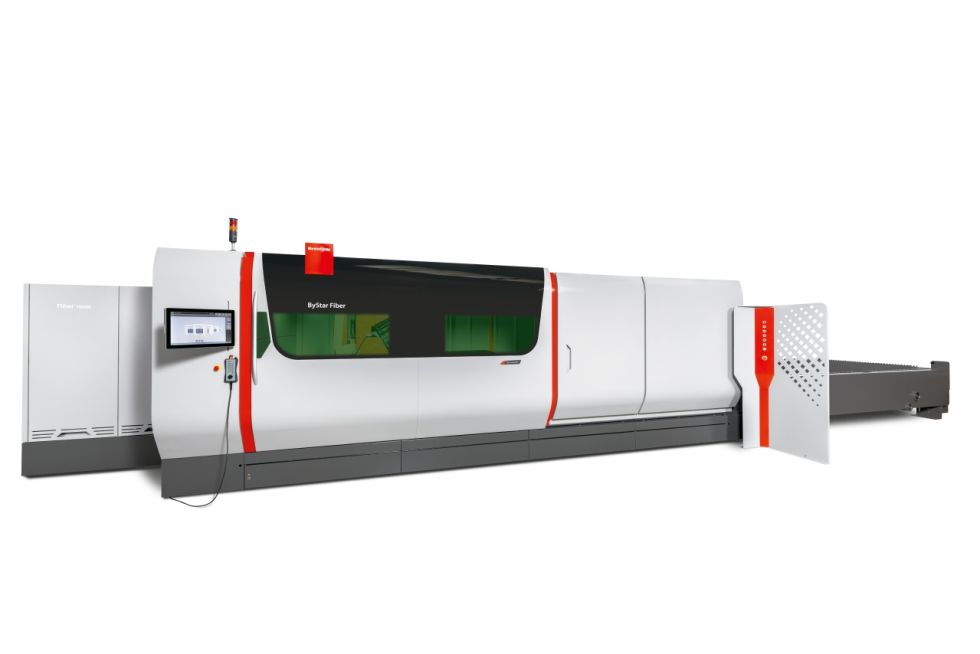

ByStar Fiber: Designed for Fiber. Unrivaled for Speed.

Now available with 8kW or 10kW Fiber Laser! The new ByStar Fiber Laser Cutting System, with its uncompromising high-end performance, is designed for users who want to rely fully on precision fiber laser technology. Users who will in the future cut their entire range of orders using the Fiber laser: from stainless steel to aluminum and mild steel, up to non-ferrous metals, such as copper and brass.

The ByStar Fiber cuts thin sheet metal at unrivaled speeds. With linear motors and a highly innovative new triangle cutting bridge design, the ByStar Fiber laser cutting machine can reach unprecedented speeds and accelerations while maintaining a very high level of edge quality and accuracy. With Power Cut, it also achieves an outstanding cutting performance in the thick sheet metal range up to 1.180-in stainless and aluminum.

The great innovation of the ByStar Fiber laser cutter lies in the single-mindedness with which the machine was designed. Right down to the smallest detail, the machine has been designed from the ground up for precision fiber laser cutting, without compromises. High cutting dynamics, thin to thick cutting capabilities, seamless automation solutions, intelligent sensor technology, and the integration into modern software systems is all possible with the new ByStar Fiber.

Xpert Press Brake: The Ultimate Bending Experience

With unique features like ByVision Bending control, Voice Control, Part ID and Bystronic Tooling and Clamping Systems, the Bystronic Xpert brake press offers unmatched efficiency and productivity capabilities for metal bending. With a comprehensive database of material bend angles and bend allowances, ByVision Bending control can make a bending professional of every user from the very first experience. Powerful and easy to operate, the Xpert brake press uses a full 22 inch full HD touch screen to display realistic 3D part animations and software driven menu selections.

In combination with the new Tool Changer System, the Xpert press brake offers a bending length of 9.8 feet. The available press capacity ranges from 150 to 320 tons. As standard, the machine comes with an intelligent bending process control and fully automatic crowning. Both functions enable a wide variety of parts to be bent with maximum repetition accuracy. With the new Tool Changer, Bystronic is now extending this combination of variety and precision with an automation solution that decreases the user's workload and reduces sources of error within the bending process.

The servo-hydraulic Xpert with dynamic press brake technology is the only press brake on the market that introduces no angle errors itself with a ram positioning accuracy of .00015-inch.

Introducing Xpert Tool Changer

Bystronic is expanding the bending process with a newly developed level of automation that enables users to bend parts quickly and with a consistently high level of quality. The new. compact Xpert Tool Changer System extends the scope and precision of the Xpert press brake with accelerated set-up times. With a state-of-the-art sensor system and integrated robotics technology, users gain an exceedingly versatile and compact bending system that sets itself up.

Users will never again bend a part using the incorrect tool, or a tool that has not been correctly inserted into the press brake's upper or lower beam. Even when bending with several stations distributed across the bending length, the automatic tool changer positions all the defined tools with the highest precision.

The Xpert Tool Changer System is of particular interest for users who want to save time and increase quality but do not want to forego flexibility.

Xpert 40 Press Brake: Profits through Speed and Portability

A compact, ultra-high speed ergonomic press brake, Xpert 40 is the fastest press brake of its size on the market. The Xpert 40 is ideal when space is limited and capacities vary. With its integrated tool storage, Xpert 40 is the FIRST press brake to combine the entire setup and production from one single station, greatly reducing non-productive bending times.

Fiber lasers have increased demand on downstream material processing because they are capable of very high parts production. The Xpert 40 with super high speed, a 6-axis ultra-high performance back gauge and high speed ram enable the cost-effective production of highly complex metal shapes and ensures the highest process efficiency to keep pace with today's popular high speed Fiber laser cutters.

Typical press brake production is 622 bends per hour (BPH).

Typical high dynamic electric or hybrid press brake production is 916 BPH.

The Xpert 40 production is 1,028 BPH.

Flexible tool selection and a press capacity up to 44 US tons makes possible a wide range of applications from thin and thicker materials. High operator efficiency is achieved through ergonomic design and individually adaptable work space. Noteworthy is the process-controlled drive unit reduces power consumption by up to 30 percent!

Xact Smart: The Smart Choice in Performance Bending

Bystronic's NEW Xact Smart brake press features standard active hydraulic crowning capabilities that can deliver accurate bend angles across the entire bed length. Easy to set up and program, Xact Smart combines high bend accuracy and advanced features into an affordable, high-value package.

Xact Smart also incorporates the powerful Bystronic ByVision Bending control system. The ByVision Bending interface uses a full 22 inch HD touch screen to display realistic 3D part animations and software driven menu selections capable of guiding operators through the step by step bending process as well as selecting bend sequences automatically. Programming is simple and intuitive.

Designed for easy tool integration, the Xact Smart press brake can easily accommodate all types of punches and dies with the appropriate clamping system.

BySmart Fiber Laser Cutter: Bridging Performance with Lower Investment Costs

With the introduction of the BySmart Fiber 3015 Laser Cutter, Bystronic is offering a high-quality performance package that enables first-time users a fast entry into laser cutting. Performance features include a highly dynamic drive system capable of high accelerations and high speeds as required by the fiber laser.

The BySmart Fiber also features the high performance Bystronic ByVision control with full 22 inch HD touch screen and software driven menu selections, making it both easy to learn and easy to operate.

The BySmart Fiber laser cutter is equipped with an automatic shuttle table capable of allowing for the loading and unloading of materials on one table while the machine is cutting on the other.

For flexibility in the investment costs, the BySmart Fiber can be fitted with a Fiber 2000, Fiber 3000 or Fiber 4000 watt laser source while still maintaining the competitive advantages of faster speeds and lower operating costs that are synonymous with Fiber laser cutting.

BySoft 7: Make It Easy

High-performance software is fundamental component of modern sheet metal processing. BySoft 7 is a robust, easy to operate CAD/CAM software package that supports both 2D and 3D CAD and provides the user with an extensive array of process scheduling and monitoring functions. BySoft 7 employs a highly intuitive structure that enables first-time users to begin working with the software quickly and easily. It simplifies processes within the factory with advanced capabilities for nesting parts, creating cutting plans, generating bending programs, simulating bending sequences, and more. Actual production costs can be determined through an embedded cost calculator.

The BySoft 7 programming system consists of four individual modules: 2D Processing, Bending, Tube Processing and Plant Manager. Plant Manager is a unique operational tool that both plans and monitors manufacturing processes, including all cutting and bending operations. It compiles all relevant machine and production data and makes it continuously available to the operator, providing maximum transparency. This is’ real-time’ system integration and the most efficient way to ensure that your process remains consistent so that your costs and margins remain consistent.

Bystronic and Lantek form strategic partnership

The need for automation and digital processing solutions is growing, and this is being amplified by Industry 4.0 trends that are changing the world of sheet metal production. The software sector is playing a central role in this change. To assist users in an automated and networked production environment with outstanding process solutions, Bystronic announces an innovative partnership with Lantek Systems working on new visions. The initial objective is to expand existing software offerings to include a Manufacturing Execution System (MES) to help customers incorporate automation and digital processes optimally into their production. Stop by the kiosk in our booth to learn more about this strategic partnership and the MES soluti

ByFinances - Turning Dreams into Reality

ByFinances is a streamlined financing option that makes purchasing the industry’s finest metal fabrication equipment an easy and economically sound decision. ByFinances completes an already impressive suite of global services with a simplified application and approval process. Now Bystronic offers you the best equipment with the best financing. Turn your Dreams into Reality with ByFinances and Best Choice!

ByFinances benefits:

- The expertise and attention of a single, dedicated finance specialist

- Convenient credit application only program

- Customized financing programs

- Independence from banks and market-rate conditions

- Efficient and fast application and approval process

- Flexible purchase or return options at lease termination

- Attractive options for lease extension

- The ability to maintain capital liquidity

Experience the future of High Performance during Fabtech at our Booth C35069 in the Central Hall where we offer continuous machine and software demonstrations. We also invite you to take a break and stop by the refreshment bar.

In manufacturing, rising above the status quo requires innovative machinery and innovative thinking. Innovation is the driver of high performance fabricating and the key to competitive differentiation. Innovative thinking is at the core of Bystronic solutions. We recognize it’s no longer how a single piece of machinery will affect the fabrication process, but how all the machines and supporting software technologies work together to create a cohesive and effective fabrication solution.

About Bystronic

Bystronic Inc. has offered customers single source service expertise for over 35 years. They provide innovative laser cutting, waterjet cutting and press brake systems, system software and comprehensive customer training and support. The company’s North American headquarters is located in Elgin, IL. Offices are also located in Toronto, Canada and Monterrey, Mexico.

For more information on Bystronic Inc. e-mail sales.us@bystronic.com or contact Frank Arteaga, Bystronic Inc. at 847-214-0300.