News Highlights from FABTECH 2015 Chicago

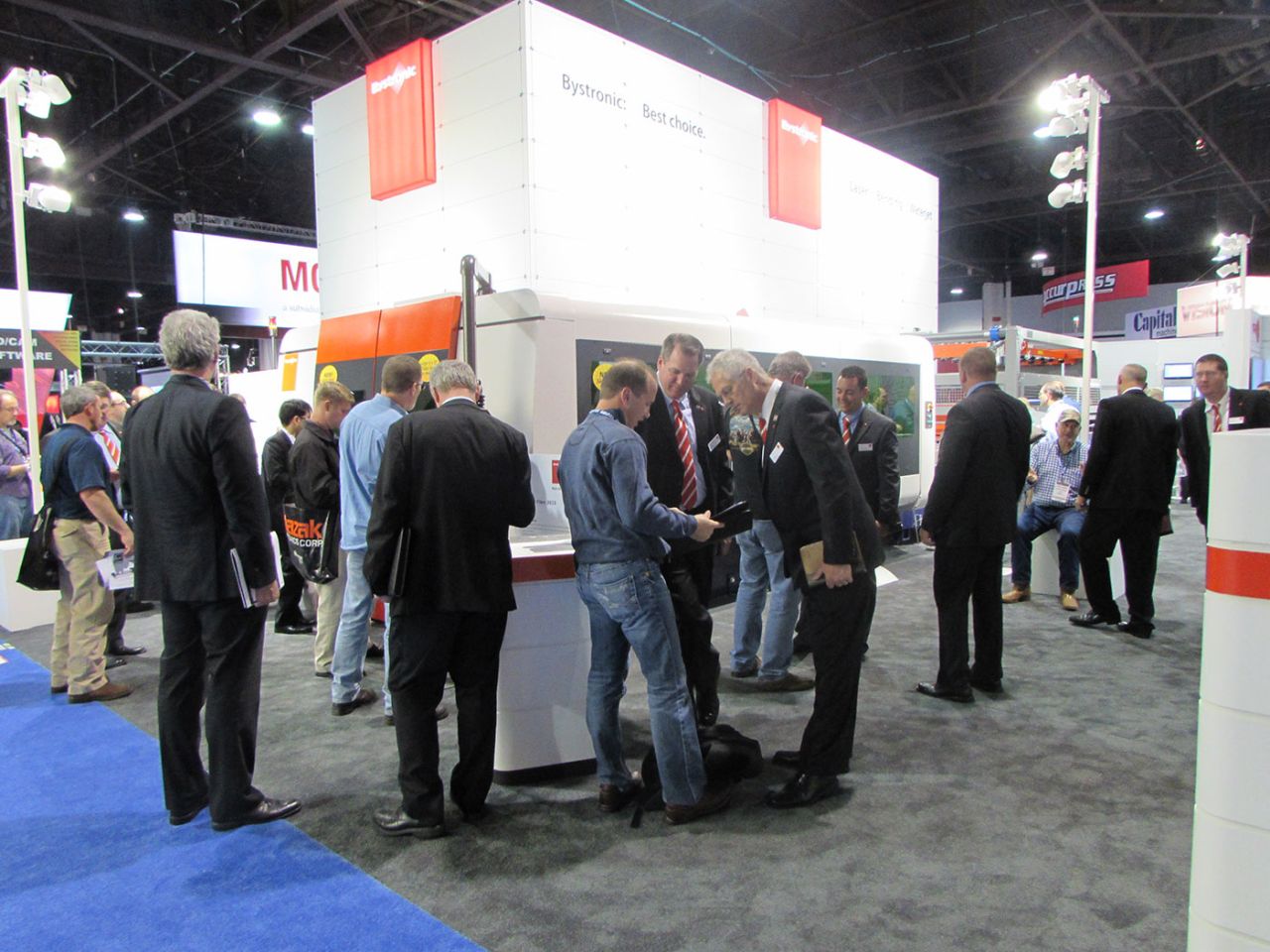

Over 43,000 attendees and 1,700 exhibitors made FABTECH 2015 the largest in its history. Enjoy highlights from our Booth S919.

During FABTECH 2015 in Chicago, Bystronic introduced its new Global Performance Line (GPL) of products - products designed to bridge performance with lower investment costs. Shown was the new BySmart Fiber laser cutting system and the new Xact Smart press brake. Performance features deliver fast cutting and bending results, lower costs and increased profits. Products also incorporate the high-performance Bystronic ByVision 22” touch screen control and are driven by Bystronic’s powerful Bysoft 7 suite of programming software.

Software drives the manufacturing process. In the Software Theater presentations focused on Industry 4.0, Cloud Computing and Fibernomics. New features added to the easy-to-operate BySoft 7 CAD/CAM software package were presented. BySoft 7 supports both 2D and 3D CAD. Considerable interested was generated around the Bystronic Industry 4.0 related software suite which comprises the latest production management and machine monitoring systems which allow users to remotely monitor their production data and make decisions in real time.

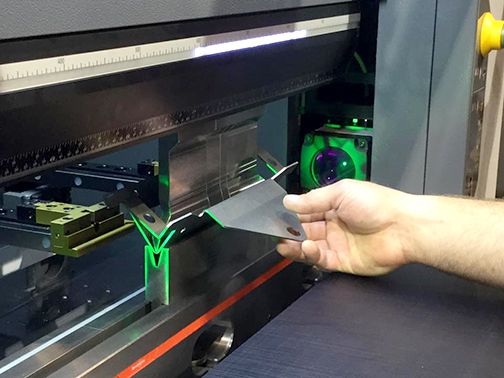

Bystronic also introduced the new high-speed Xpert 40 compact press brake. The fastest press brake on the market, the Xpert 40 boasts an average of 65% more bends per hour than a conventional brake and 12% faster than a hybrid or electric brake. “Turbo charged” back gauge and ram speeds ensure the highest process efficiency to keep pace with today’s high speed Fiber laser cutting machines.

The ultra-high performance back gauge system enables the cost-efficient production of highly complex sheet metal shapes. With its integrated tool storage, it is the first press brake to combine the entire setup and production from one single station, greatly reducing non-productive bending times.

About Bystronic:

Bystronic Inc. has offered customers single source service expertise for over 35 years. They provide innovative laser cutting, waterjet cutting, press brakes, automation, system software and comprehensive customer training and support. The company’s North American headquarters is located in Elgin, IL. Offices are also located in Toronto, Canada and Guadalajara, Mexico.

For more information on Bystronic Inc., contact sales.us@bystronic.com.