News Size Matters in Waterjet Cutting

Excerpt from “Size Matters in Waterjet Cutting” article in Canadian Industrial Machinery (CIM) magazine (June issue) Bystronic’s VP Sales, Brody Fanning, discusses waterjet cutting of large parts.

Large-part Waterjet Cutting - Waterjet setups should change depending on the size, thickness or the parts being cut.

CIM: Is taper a problem when cutting large parts on a waterjet?

Fanning: In general terms, the thicker the part, the more pronounced the effect of taper and the more pronounced the stream lag.

CIM: What’s the best way to unload large parts?

Fanning: Of course, loading and unloading of large parts create certain risks and difficulties that small parts do not have. Utilizing a jib or overhead crane can simplify the process somewhat.

CIM: Is maintaining positional accuracy tougher when producing large parts?Fanning: Depending on the machine manufacturer, large machines may be less accurate overall than smaller ones. That is not the case with Bystronic’s machines. With most equipment available on the market today, positional accuracy should be fairly repeatable from one part to the next.

CIM: What industries can take advantage of this technology?

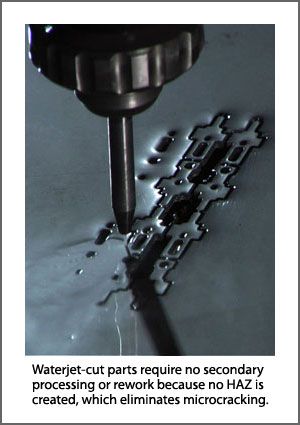

Fanning: Aerospace, signage, packaging equipment, oil field, transportation, and many other industries can all benefit from large waterjets. Any industry where the material is difficult to process, or if it’s challenging and expensive to weld smaller pieces together, can benefit from large-format waterjet machines.CIM: How does the HAZ affect large parts?

Fanning:HAZ causes several issues in all parts, including large ones, that can be a problem for certain applications. HAZ can cause embrittlement, stress cracks, discoloration, edge hardening, and even odors in cut parts.

CIM: What are the benefits of little pressure being placed on a large part?

Fanning: The waterjet stream exerts minimal downward force on the workpiece being cut—something on the order of 7 to 10 pounds of downward force. This is usually not a problem unless the material being cut is fragile, such as glass.CIM: How should large parts be supported on the machine’s bed?

Fanning: Typically there are slats (vertical pieces of support material) every couple of inches to support the workpiece.

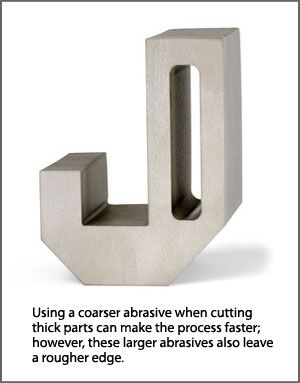

CIM: As parts get larger, should a larger abrasive size be used?

Fanning: As the material gets thicker, there may be a benefit to using a coarser abrasive. However, coarser abrasives remove material more quickly, but leave a rougher edge.CIM: What is the relationship between feature size and stream diameter?

Fanning: Typically when cutting thick parts, the kerf diameter will be in the neighborhood of 0.040 in. to 0.060 in., depending on the pump’s horsepower and nozzle being used. For thicker parts, the smallest-diameter hole you would want to try to interpolate would about 3X the nozzle diameter.

CIM: Is it possible to increase the diameter of the stream?

Fanning: Yes. The diameter of the stream can be changed during the setup process prior to cutting. To do this, the operator changes the orifice that the water flows through and the nozzle that the water and abrasive flow through.

The largest orifice that can be used is dictated by the horsepower and pressure rating of the pump. The nozzle diameter is typically 3X the orifice diameter.

www.bystronicusa.com