Blog Sustainability in Laser Cutting: Innovations in Energy Efficiency and Waste Reduction

As more people recognize our impact on the environment, businesses are under increasing pressure to operate more sustainably. One smart way to do this is to review how products are made and find ways to make production more efficient. Not only does this help the environment, but it also strengthens long-term business success and encourages the sheet metal industry to lower its carbon footprint.

“We are passionate about creating an impact for a sustainable future with sheet metal and beyond.”

Domenico Iacovelli, CEO of Bystronic

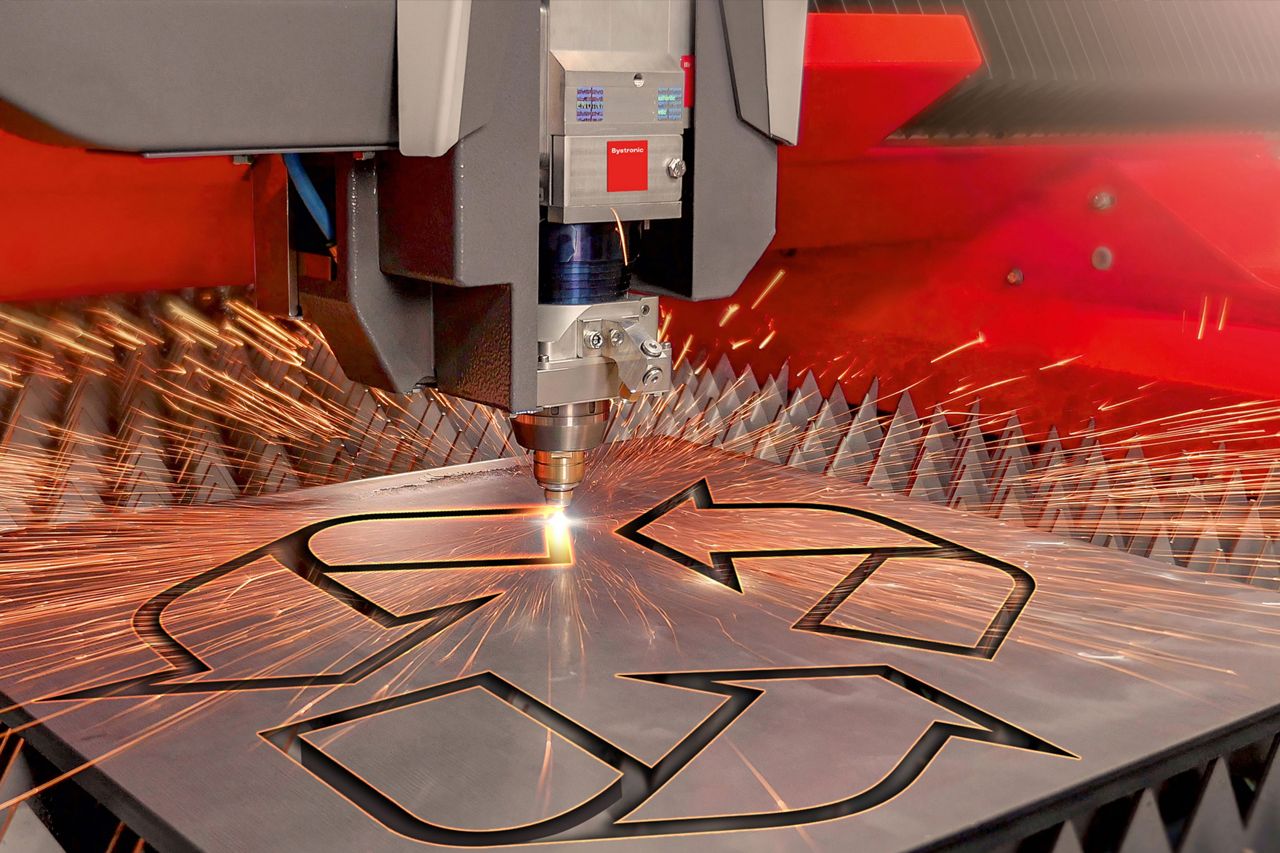

Laser cutting exemplifies this evolution. Known for its precision, speed, and cost-effectiveness, it is generally more energy-efficient than traditional mechanical methods. Its ability to produce intricate, accurate designs helps manufacturers optimize raw material usage and reduce waste—key components of sustainable manufacturing

Making the Right Choice

As with any industrial process, it’s important to consider the environmental impact of sheet metal cutting and bending technologies. Integration with robotics and smart manufacturing further reduces waste and increases efficiency.

Fiber Lasers Offer Promise

Fiber lasers stand out for their energy efficiency, lower maintenance needs, and faster cutting speeds. They eliminate gas use—cutting down on emissions—and require less upkeep and fewer replacements, further reducing environmental impact.

These systems also support a circular economy by enabling the use of recyclable and sustainable materials. This growing model of minimizing waste and reusing materials aligns closely with the goals of modern manufacturers.

Fiber laser cutting also reduces waste through narrow kerf widths, precise cutting, and efficient nesting of parts. Compared to sawing or shearing, this results in less scrap and reduces the need for additional finishing, such as deburring or sanding.

Laser Cutting Leads to Shorter Production Cycles

Laser cutting machines operate faster and require less setup than traditional systems, leading to shorter cycles and lower energy use.

Laser cutting is also a cleaner process overall, with fewer emissions than older methods that release harmful fumes and particles.

Eco-Friendly Advancements in Laser Cutting

Modern sheet metal cutting and bending systems are designed to reduce waste, optimize material use, and improve productivity. These systems now include features specifically aimed at supporting sustainability, such as:

- Intelligent Cutting Process (ICP): A coaxial camera films through the nozzle to monitor cutting, enabling proactive adjustments that prevent material waste and downtime.

- Parameter Wizard with Artificial Intelligence (AI): AI-based tools optimize cutting parameters when new materials are introduced, reducing time-consuming trial-and-error.

- Laser Source and Chiller Systems: As primary energy consumers, these are optimized to reduce carbon emissions and boost energy efficiency.

Nesting Software Maximizes Raw Material Usage

Advanced nesting software arranges part layouts to maximize each material sheet, significantly reducing waste—a major advantage when working with costly materials.

As technology evolves, laser cutting’s role in sustainable manufacturing will only grow. Advances in laser sources, automation, and material processing are expanding its potential. Manufacturers embracing these innovations can expect reduced environmental impact, lower costs, and stronger market positions.

A Sustainable Future in Manufacturing

Looking forward, laser cutting will remain central to improving manufacturing efficiency and reducing environmental impact. Ongoing innovation is laying the foundation for a more sustainable sheet metal industry.

Despite some challenges, the sustainability benefits of laser cutting make it an essential tool for manufacturers committed to greener practices. By adopting these technologies, companies can help shape a cleaner, more sustainable industrial landscape.