Stainless steel processing With machines, software and automation from Bystronic

Stainless steel processing in Swiss quality More efficiency for more profit

We set new standards in stainless steel processing with our innovative solutions:

- Laser cutting machines and tube lasers

- Press brakes

- Automations

- Software

We offer customized applications for your individual needs. Discover the future of stainless steel processing today!

Do you have questions about processing stainless steel with Bystronic? We will be happy to help you.

Stainless steel processing with laser cutting machines

Our modern laser cutting machines offer precise and reliable processing of stainless steel. They produce clean cuts with high accuracy, which is essential in many industries such as:

- Manufacturing,

- Automotive industry

- Aerospace

We use specific parameters to ensure that our machines achieve optimum results even with the hardness and reflective surface of stainless steel. This is how we guarantee consistent quality.

Our Smart Features support you in achieving precise results:

- The "Intelligent Cutting Process (ICP)" provides you with a direct insight into the cutting process. This is made possible by a coaxial camera that films through the nozzle of the fiber laser.

- The "Parameter Wizard" determines the perfect parameters for processing stainless steel with N2 in just a few minutes.

Stainless steel processing with tube lasers

Increase the efficiency of your tube laser operation with an impressive laser power of up to 4 kW. Improve the:

- Precision

- User friendliness

- Automatic setup for all profiles, including open and elliptical pipes

- Quality and performance in your production

Our machines can handle pipe lengths from 6000 to 12500 mm and cross-sections from 10 to 323.9 mm with ease. They enable the processing of a wide range of stainless steel profiles: ○ ◻ ▯ ⬭ U C L -.

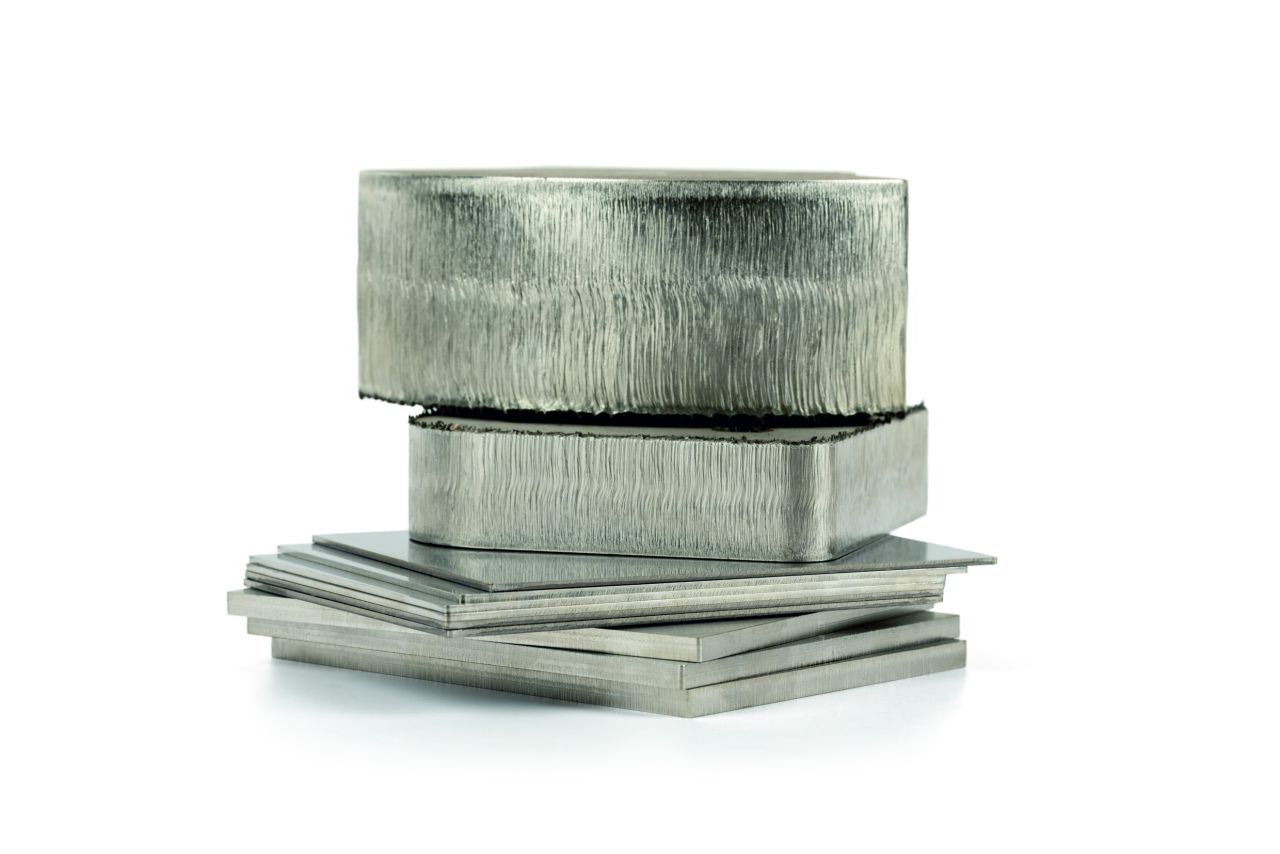

Stainless steel processing with press brakes

Bystronic offers an extensive range of press brakes: From entry-level models to high-performance machines for complex bending processes. Our press brakes can handle sheet thicknesses from 1 to 16 mm .

In applications such as the automotive or aviation industry, the materials used must be corrosion-free. A high-quality surface finish is crucial here to prevent scratches and discoloration.

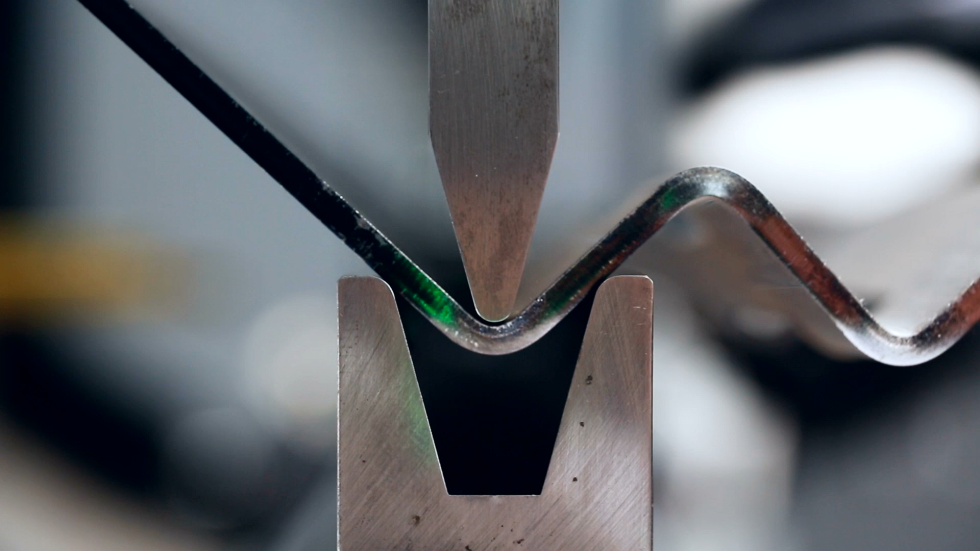

We use bending parameters specially adapted to stainless steel and suitable bending tools for processing stainless steel. Smart features also ensure consistent quality:

- LAMS: This optical angle measuring system is based on lasers and cameras and supports the bending accuracy of the machines with the help of sensors.

- Curve generator: This generator uses a series of variables to create a bending curve. This enables the machine to always approach the same position and bend at the perfect angle. You get reliable results for every processed part.

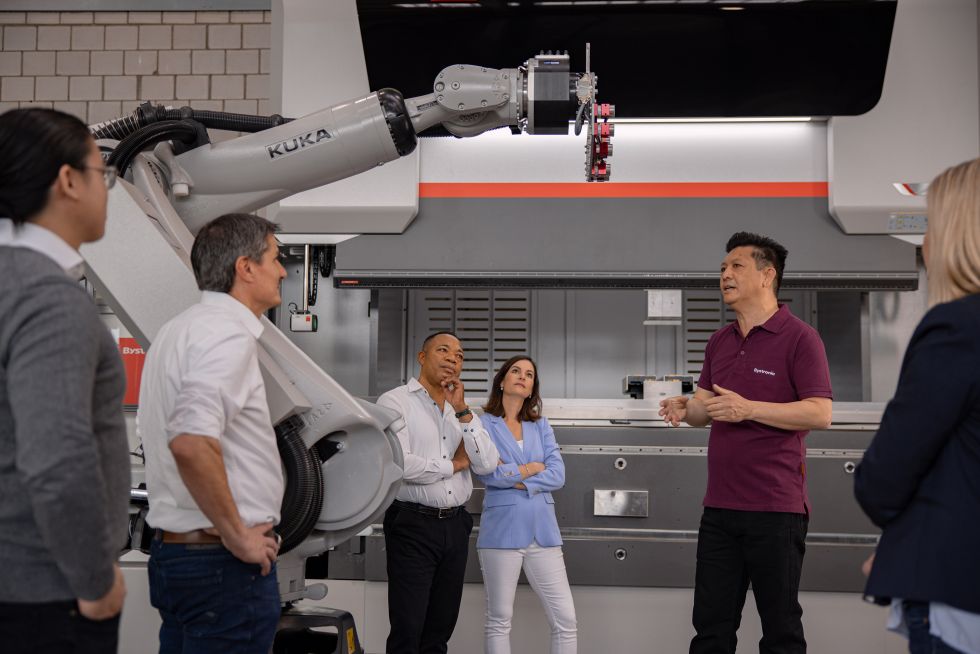

Our stainless steel processing specialists will be happy to support you

Our team is at your side in every phase of your project:

- Pre-project phase - We offer comprehensive advice based on your business objectives. We work with you to develop the ideal solution for you.

- Preparation phase - We support you throughout the entire planning process from the first meetings to the completion of the final layout.

- Realization - We accompany you from delivery to installation and are always at your side.

- Commissioning - Our team ensures that all necessary tests for successful customer acceptance are carried out properly.

- Start of production - We are at your side even after the start of the project and work with you to optimize your production.

Fit for the stainless-steel processing of the future with automation

Start optimizing your production processes today on the way to digital production. With Bystronic, you can gradually realize your goal of a fully integrated smart factory of the future.

Our automation solutions are of first-class performance and quality:

- Laser cutting machines: Rely on a fully automatic sheet loading process with weight control on the elevator and monitoring of the tilted parts when unloading the sheets. This way, your automated production is reliable and safe.

- Press brakes: Our solutions for bending automation guarantee precision and bending quality. Fully or semi-automated processes save valuable time and reduce costs.

Software solutions for simple stainless-steel processing

Invest in the digitalization of your company with the BySoft Suite. Increase transparency and control along your entire supply chain:

- Connect all departments seamlessly.

- Improve the efficiency of your tube laser processes.

- Integrate external systems and machines smoothly.

- Relieve your employees of routine tasks so that they can dedicate more time to more demanding activities.

More sustainability with Bystronic

Bystronic's sustainability strategy is based on three central pillars:

- Improving our own sustainability practices.

- Promoting greater sustainability among our customers.

- Actively helping to shape a more responsible future in our industry.

That is why we are working intensively on the processing of green steel. It has the same material properties as stainless steel. However, it is produced without the emission of carbon dioxide. This sustainable sheet steel can be processed easily with all our machines.