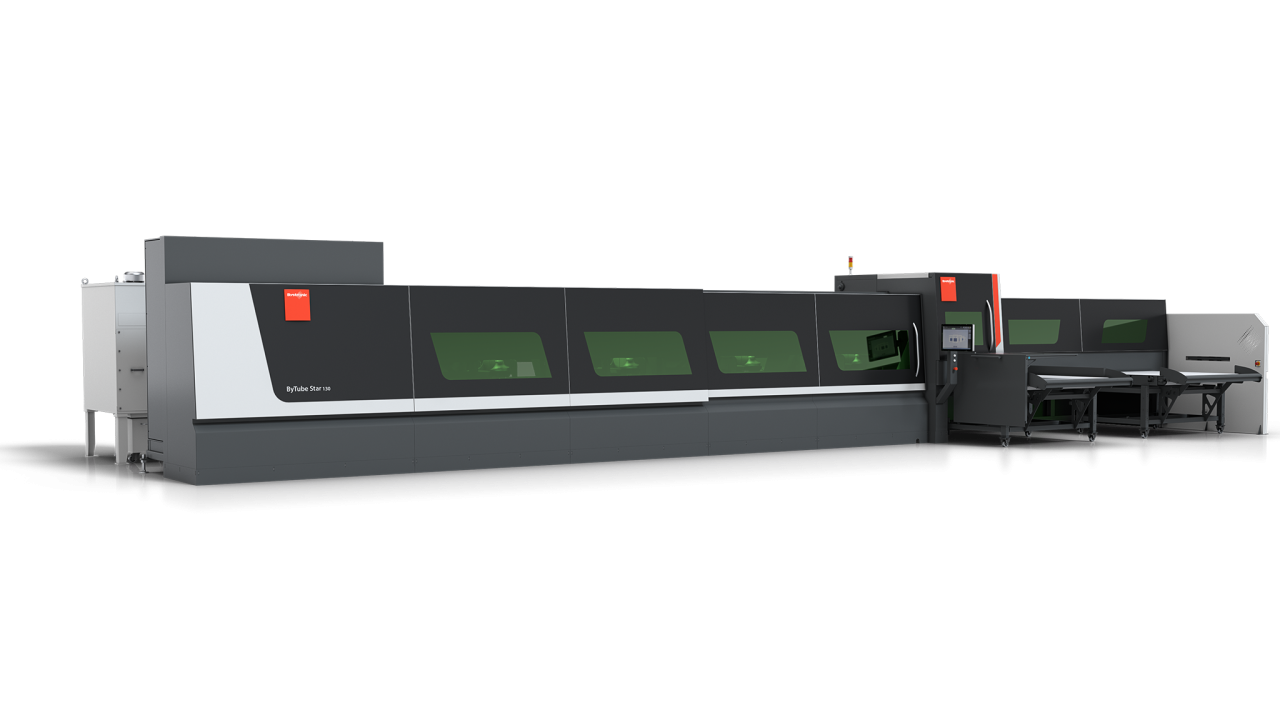

ByTube Star 130 High-performance tube laser cutting

Increase quality Fast and flexible tube laser cutting

Accelerate the laser cutting of tubes and profiles with the ByTube Star 130. Tube laser cutting with our high-end tube laser boosts the quality and performance in your production through:

- Highest precision

- Ease of use

- Fully automatic setup of all profiles, including open and elliptical tubes

Fully automatic setup Also for open profiles and elliptical tubes

With the ByTube Star 130 you can process the full bandwidth from 10 to 130 mm. This also applies to open profiles. Without the operator´s manual intervention:

- There are no downtimes during the setup.

- The fully automatic setup also increases the safety of your operators

- At the same time it reduces the risk of human error.

More power Now with 4 kW

The new increased laser power of 4 kilowatts ensures an even faster cut. With this improvement, you can produce faster and more efficiently, increasing your productivity and competitiveness. This leads to an overall higher quality in tube laser cutting.

Quick Cut Quality at high speed

An additional linear axis of the cutting head ensures highest speed and quality under all conditions. We also guarantee this for very small tubes.

Increase quality Fast and flexible tube laser cutting

Accelerate the laser cutting of tubes and profiles with the ByTube Star 130. Tube laser cutting with our high-end tube laser boosts the quality and performance in your production through:

- Highest precision

- Ease of use

- Fully automatic setup of all profiles, including open and elliptical tubes

Fully automatic setup Also for open profiles and elliptical tubes

With the ByTube Star 130 you can process the full bandwidth from 10 to 130 mm. This also applies to open profiles. Without the operator´s manual intervention:

- There are no downtimes during the setup.

- The fully automatic setup also increases the safety of your operators

- At the same time it reduces the risk of human error.

More power Now with 4 kW

The new increased laser power of 4 kilowatts ensures an even faster cut. With this improvement, you can produce faster and more efficiently, increasing your productivity and competitiveness. This leads to an overall higher quality in tube laser cutting.

Quick Cut Quality at high speed

An additional linear axis of the cutting head ensures highest speed and quality under all conditions. We also guarantee this for very small tubes.

Your simple entry into tube laser cutting. Learn more about our ByTube Star 130.

Technical specifications All information on the ByTube Star 130

| ByTube Star 130 | |

| Min. Tube length (with automatic loading) | 2500 mm |

| Max. Tube length | 6500 – 8500 mm |

| Max. Tube weight | 17 kg/m |

| Tube sections | O ◻ ▯ ⬭ U C L — |

| Dimensions round sections (min. – max.) | Ø 10 – 130 mm |

| Dimensions square sections (min.–max.) | 10 x 10 – 130 x 130 mm |

| Dimensions other closed sections (min.–max. length of the sides) | Ø 10 – 130 mm |

| Dimension angles (L) with equal and unequal legs (min.–max.) | 19–120 mm |

| Dimension channels, UPN, UPE (min.–max.) | 19–127 mm |

| Dimension flat bars | 40 – 130 mm |

| Thickness flat bars | 5 - 15*mm |

| Max. linear speed of axis X / Y / Z | 200 / 60 / 60 m/min |

| Max. rotation speed of mandrels | 250 r.p.m. |

| Available unloading lengths | 2000 – 4000 – 6100 mm |

| Number of controlled axis | 8 |

| Machine weight** | 12 000 kg |

| Control interface | BySoft Cell Control Tube |

Laser sources for the ByTube Star Tube laser cutting with up to 4 kilowatts of laser power

The ByTube Star 130 eliminates the need for time-consuming drilling, sawing, milling, or punching. The increased laser power and the optimized cutting process allows you fast, automated and precise cutting:

- Closed tubes

- Angles

- Channels

- Flat bars

- Ellipses

Our specialists for tube laser cutting machines are happy to advise you.

Features & options

-

Productivity & Efficiency -

Quality -

Flexibilty -

Simplicity -

Future Fit -

Peace of Mind -

Business Success

Fully automatic set-up (incl open sections)

No downtime for set-up means more time for cutting, so more productivity.

4kW fibre laser

Higher speed, regardless of the type of material, material thickness or size.

Quick Cut – Performance mode

Maximum cutting performance for maximum productivity. The combination of movements of cutting head and tube achieves the highest acceleration values to reach the maximum cutting performance.

Preparation for N2 generator

Stay independent of your gas provider and ensure a consistent supply of gas and cutting quality.

Active tube support during cutting process

The tube support by controlled axis both in the loading and in the unloading helps to keep the tube straight. Accuracy is guaranteed even with long tubes.

4kW fibre laser

The database of cutting parameters enables us to achieve the best performance and quality for different materials and material thicknesses.

Laserscan

Real-time compensation of tube bending enables high cutting accuracy, even with low-quality material.

Quick Cut – Quality mode

Small geometries, no vibrations and increased cutting quality - the head can machine tubes without repositioning.

Parameters for brass and copper + safety

More cutting possibilities with a complete set of parameters. The copper and brass package consists of a database of cutting parameters and the safety systems. In addition, the operator is protected from possible back reflections.

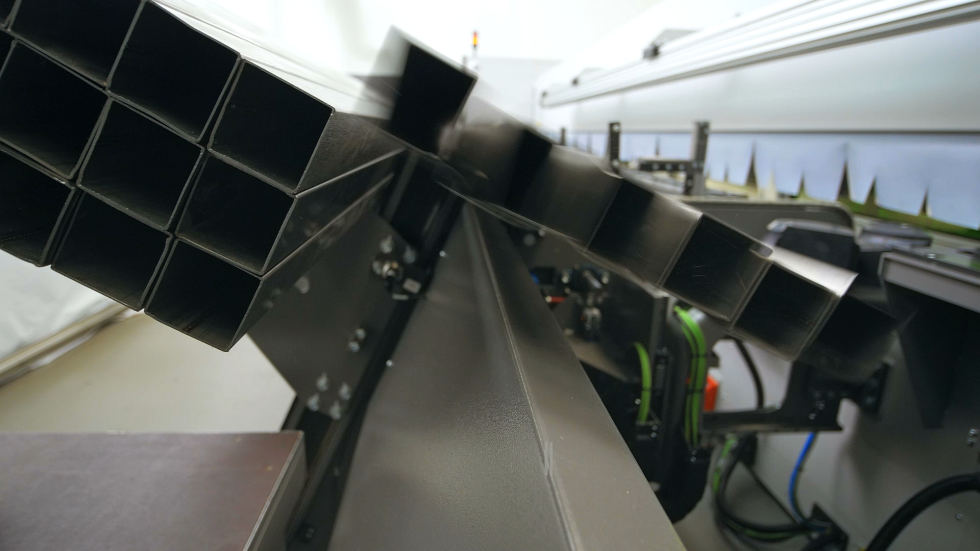

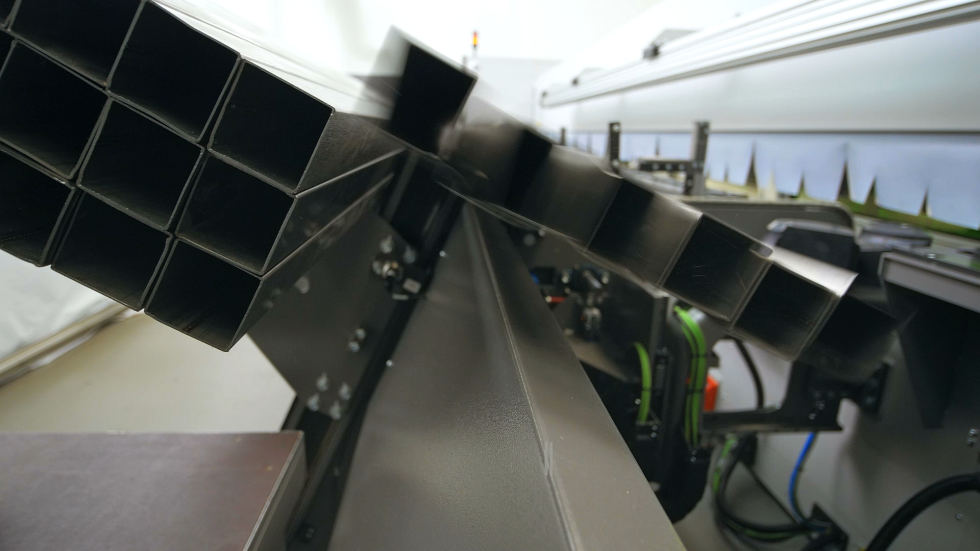

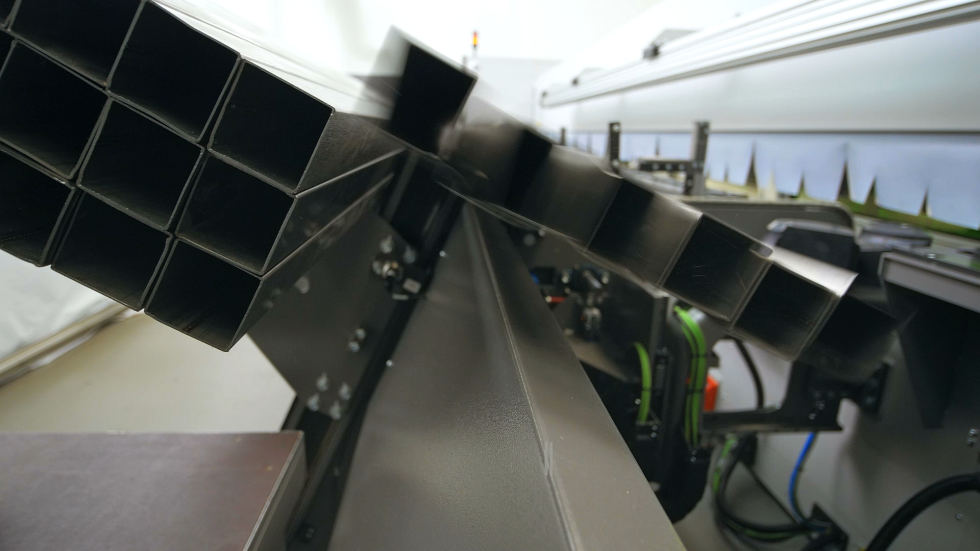

Bundle loader

A simple device that is straightforward to set up. Using the bundle loader, you can load bundles of tubes, single bars or open sections.

Conveyor belts for cut parts

Conveyor belts collect parts after cutting and give the operator sufficient time for logistics, packaging or carrying out other tasks. The parts fall directly into boxes or pallets.

Open sections

The ByTube Star 130 can process not only closed tubes, but also angles, channels and flat bars - no set-up required.

Fully automatic set-up (incl. open sections)

Whenever a change of production is required, the operator just has to load the material, run the program and start the machine. This makes ByTube Star 130 not only easy to operate. It is also suitable for entry-level users in the tube business.

HMI / ByVision Tube

The ByVision Tube user interface enables intuitive operator guidance via a touch screen. It’s optimally tailored to Bystronic’s machine systems and supports the entire range of applications.

Weld seam search camera

The automatic detection of the weld seam position on tube inner surface is needed for many applications, especially when tube is bent after cutting

Laserscan

High accuracy is ensured in all cutting conditions with low impact on process speed. This reduces the quality assurance work required for cut parts.

Fully automatic set-up (incl. open sections)

Machine is ready for the future, because connection with storage and/or sorting devices is facilitated by the fully automatic set-up for every tube or profile.

Bundle loader

Bundle loader is easily accessible for the manual loading of bundles. It is also suitable for easy connection with storage devices. Continuous loading of tubes is guaranteed, minimising downtime, logistics work, and reducing the risk of operator errors.

HMI / ByVision Tube

The ByVision Tube user interface enables intuitive operator guidance via a touch screen. It is optimally tailored to Bystronic’s machine systems and supports the full bandwidth of applications.

Preparation for N2 generator

Stay independent of your gas provider and ensure a consistent supply of gas and cutting quality.

Fully automatic set-up (incl. open sections)

Less risk of operator errors and enhanced safety for the operators.

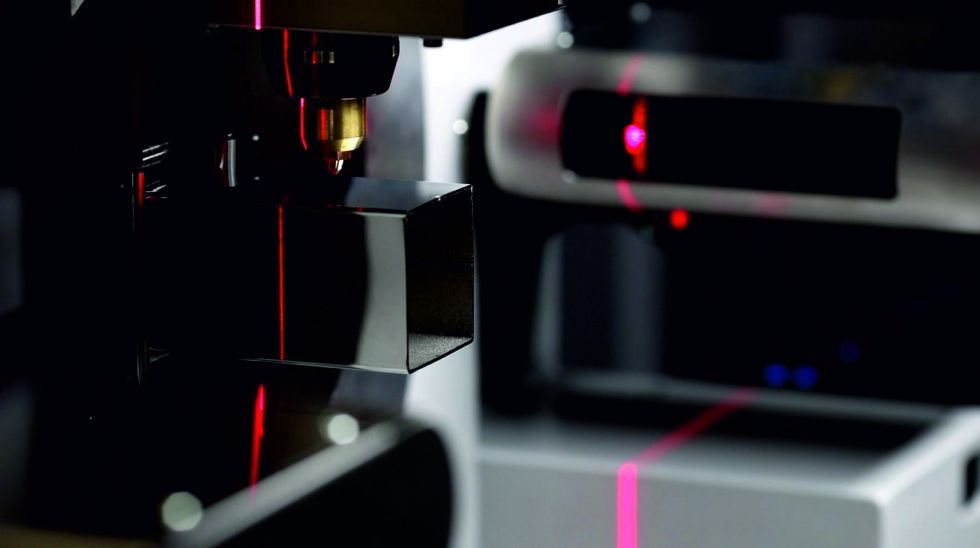

Cutting head

The cutting head is fibre laser technology “made by Bystronic”. This means less work for service teams and purchasing.

Laserscan

Always guarantees high accuracy in all cutting conditions, even with low-quality material.

Quick Cut – Quality mode

Holes and other features always cut with perfect quality even in difficult conditions. This results in less waste and fewer rejects.

Fully automatic set-up (incl. open sections)

Downtime as a consequence of manual machine set-up is drastically reduced thanks the fully automatic set-up. This results in more throughput and lower cost per part.

4kW fibre laser

Maximum productivity thanks to the highest power available for a small tube laser. The best cut quality on thick materials.

Open sections

The ByTube Star 130 processes more than standard tubes. It can also handle angles, channels and flat bars.

Preparation for N2 generator

Stay independent of your gas provider and ensure a consistent supply of gas and cutting quality.

Fully automatic set-up (incl open sections)

No downtime for set-up means more time for cutting, so more productivity.

4kW fibre laser

Higher speed, regardless of the type of material, material thickness or size.

Quick Cut – Performance mode

Maximum cutting performance for maximum productivity. The combination of movements of cutting head and tube achieves the highest acceleration values to reach the maximum cutting performance.

Preparation for N2 generator

Stay independent of your gas provider and ensure a consistent supply of gas and cutting quality.

Active tube support during cutting process

The tube support by controlled axis both in the loading and in the unloading helps to keep the tube straight. Accuracy is guaranteed even with long tubes.

4kW fibre laser

The database of cutting parameters enables us to achieve the best performance and quality for different materials and material thicknesses.

Laserscan

Real-time compensation of tube bending enables high cutting accuracy, even with low-quality material.

Quick Cut – Quality mode

Small geometries, no vibrations and increased cutting quality - the head can machine tubes without repositioning.

Parameters for brass and copper + safety

More cutting possibilities with a complete set of parameters. The copper and brass package consists of a database of cutting parameters and the safety systems. In addition, the operator is protected from possible back reflections.

Bundle loader

A simple device that is straightforward to set up. Using the bundle loader, you can load bundles of tubes, single bars or open sections.

Conveyor belts for cut parts

Conveyor belts collect parts after cutting and give the operator sufficient time for logistics, packaging or carrying out other tasks. The parts fall directly into boxes or pallets.

Open sections

The ByTube Star 130 can process not only closed tubes, but also angles, channels and flat bars - no set-up required.

Fully automatic set-up (incl. open sections)

Whenever a change of production is required, the operator just has to load the material, run the program and start the machine. This makes ByTube Star 130 not only easy to operate. It is also suitable for entry-level users in the tube business.

HMI / ByVision Tube

The ByVision Tube user interface enables intuitive operator guidance via a touch screen. It’s optimally tailored to Bystronic’s machine systems and supports the entire range of applications.

Weld seam search camera

The automatic detection of the weld seam position on tube inner surface is needed for many applications, especially when tube is bent after cutting

Laserscan

High accuracy is ensured in all cutting conditions with low impact on process speed. This reduces the quality assurance work required for cut parts.

Fully automatic set-up (incl. open sections)

Machine is ready for the future, because connection with storage and/or sorting devices is facilitated by the fully automatic set-up for every tube or profile.

Bundle loader

Bundle loader is easily accessible for the manual loading of bundles. It is also suitable for easy connection with storage devices. Continuous loading of tubes is guaranteed, minimising downtime, logistics work, and reducing the risk of operator errors.

HMI / ByVision Tube

The ByVision Tube user interface enables intuitive operator guidance via a touch screen. It is optimally tailored to Bystronic’s machine systems and supports the full bandwidth of applications.

Preparation for N2 generator

Stay independent of your gas provider and ensure a consistent supply of gas and cutting quality.

Fully automatic set-up (incl. open sections)

Less risk of operator errors and enhanced safety for the operators.

Cutting head

The cutting head is fibre laser technology “made by Bystronic”. This means less work for service teams and purchasing.

Laserscan

Always guarantees high accuracy in all cutting conditions, even with low-quality material.

Quick Cut – Quality mode

Holes and other features always cut with perfect quality even in difficult conditions. This results in less waste and fewer rejects.

Fully automatic set-up (incl. open sections)

Downtime as a consequence of manual machine set-up is drastically reduced thanks the fully automatic set-up. This results in more throughput and lower cost per part.

4kW fibre laser

Maximum productivity thanks to the highest power available for a small tube laser. The best cut quality on thick materials.

Open sections

The ByTube Star 130 processes more than standard tubes. It can also handle angles, channels and flat bars.

Preparation for N2 generator

Stay independent of your gas provider and ensure a consistent supply of gas and cutting quality.

Videos ByTube Star

With the ByTube Star 130 you benefit from numerous services in just one machine:

- Fully automatic setup

- User-friendly interface

- Enhanced speed

- Improved cutting precision

Highlights from the video

Get started easily

Tried-and-tested technology and a user-friendly interface facilitate your first steps into the world of tube laser cutting.

Fully automatic setup

Process the full range of tubes, ellipses, and profiles with sizes from 10 to 130 mm.

Quick Cut feature

An additional linear axis of the cutting head delivers maximum speed and quality under all cutting conditions.

Laserscan feature

The real-time compensation of tube deflections further enhances the precision during the cutting process.

Video tutorials

Bystronic Service Tailor-made for your needs and smooth production

ByCare packages

Our trained service experts ensure efficient production processes and safety for your employees. Depending on the requirements, we offer packages with basic to all-around services.

360° Customer Advisor

We analyze your production and determine your strengths and weaknesses. Based on this information, you can optimize processes and decrease downtime.

Our services

We maintain and repair your Bystronic systems. Optionally, you can obtain upgrades to retrofit your system or accessories to fine-tune your solution. Upon request, we can also perform a general overhaul.

Our service experts are always there for you – quickly and in person

Software for your tube laser BySoft Cell Control Tube: Convenient guidance through the process

Simplify the tube laser cutting process with our software. Every function on the touch screen is simple to understand. From the visualization of parts right through to the monitoring of the production process – the correct settings are selected in a fast and simple workflow.

BySoft Suite for networked production Software for efficient processes

The future of sheet processing lies in intelligent production. In order to master these challenges, Bystronic has developed a trend-setting software. It enables your company to optimally control your production. By networking all areas, the software offers seamless communication and efficient control of all processes.

Let Bystronic lead you into the digital future of tube laser cutting.