Metal processing for the automotive industry Smart solutions for complex and safe components in automotive engineering

Innovative metal processing for growing automotive requirements

At Bystronic, we continuously strive to drive innovation in sheet metal and metal processing.

Our laser cutting machines, tube lasers, press brakes, automation systems and software solutions enable you to process a wide variety of materials.

Your advantages

- We offer you the support you need to manufacture complex automotive components precisely and efficiently.

- Increase the performance and efficiency of your production.

- Meet the automotive industry's stringent requirements for lightweight construction, complexity and safety.

Remaining competitive with automation

By automating manufacturing processes, you increase efficiency and reduce costs at the same time.

Quality all along the production line

Ensuring high quality standards is critical to ensuring vehicle safety. Our machines do it for you.

Complex designs and new materials

With Bystronic machines, demanding shapes and geometries are possible without any problems. They also create new metal alloys effortlessly.

You offer metal processing for the automotive industry? We help you achieve higher quality and more efficient production.

How you can profit with Bystronic

Individual solutions for your automotive requirements

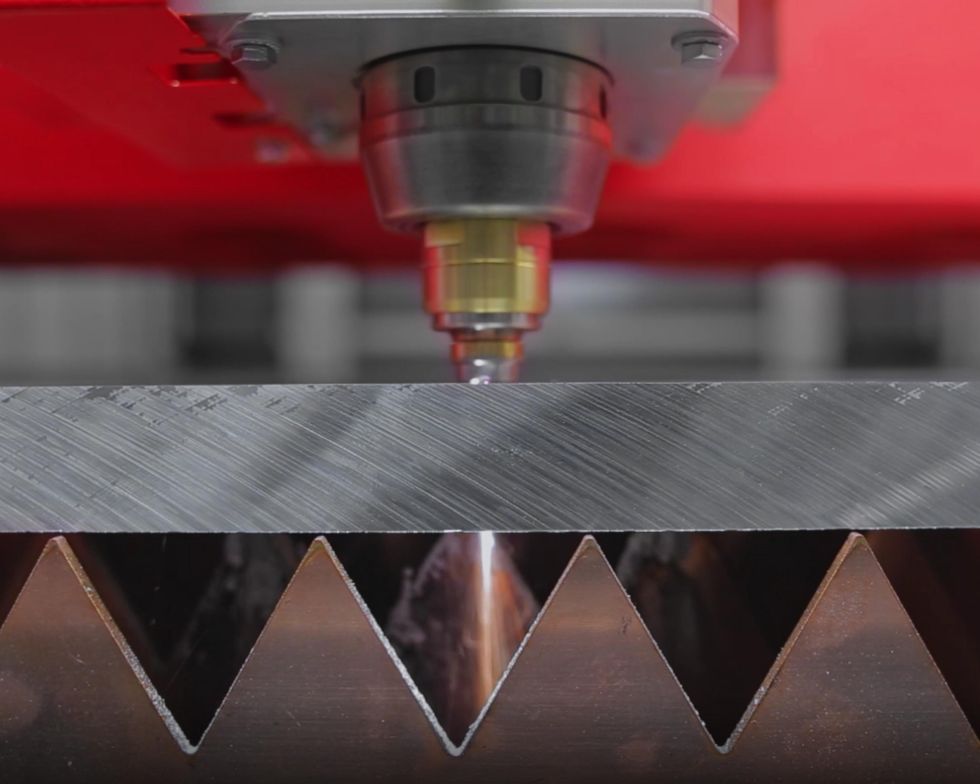

Laser cutting machines

Cut precise car body parts from various sheets with up to 30 kW laser power. Benefit from high cutting speed and intelligent cutting process to meet automotive requirements.

Tube laser

Process piping, exhaust systems and frame structures, etc. precisely and energy-efficiently. Our tube lasers use 2D and 3D technology for precise metal processing while reducing maintenance.

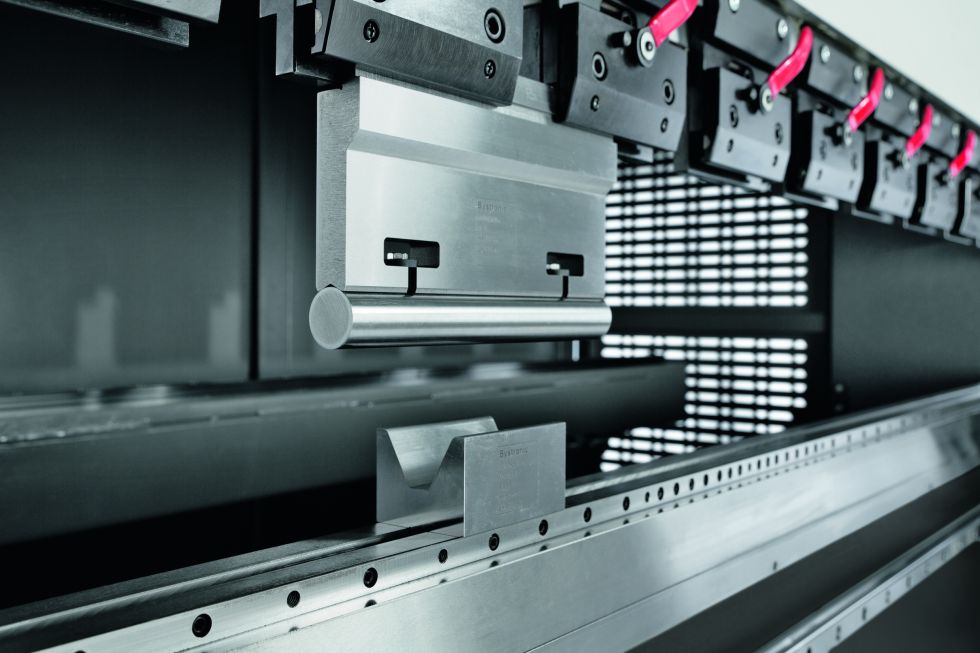

Press Brake

Bend body parts and chassis components effortlessly with our high-performance press brakes. Easy operation and intuitive software enable reliable results in terms of strength, shape, aesthetics and quality.

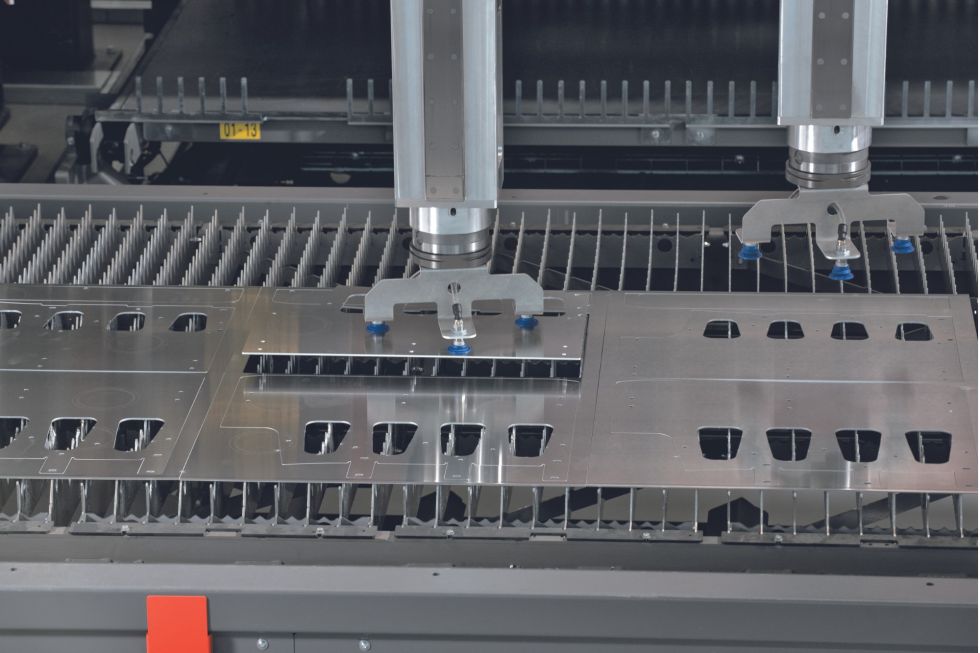

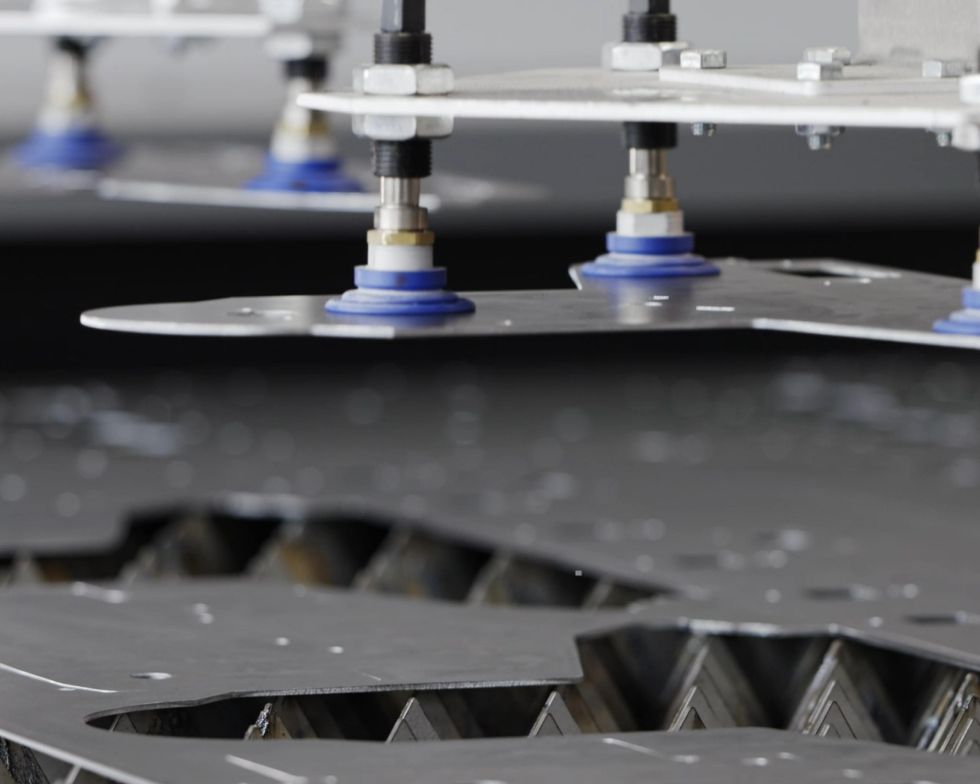

Laser automation

Our laser automation offers high precision and repeatability. Benefit from automatic sheet metal loading process and part verification during unloading. Stay competitive with reliable automated production

Would you like to learn more about Bystronic metalworking products and how you can use them in automotive manufacturing? We will be happy to help you.

Important materials for automotive construction

In automotive engineering, the specific material requirements are highly dependent on individual customer requirements and designs. However, the following materials are used particularly frequently in this industry:

- Steel

- Stainless steel

- Aluminum

- Copper

- Brass

- Titanium

Get Bystronic at your side as a partner. We advise you and bring your company into the future of automotive engineering.

Our promise to you

With Bystronic as your reliable partner in automotive engineering, you are always one step ahead when it comes to technology and innovation!

Our dedicated Bystronic Service is at your side in every situation. We solve your challenges quickly and specifically so that you can concentrate on your core business.

In the automotive industry in particular, precise metalworking is crucial for the necessary safety. Trust in us when it comes to maximum precision.