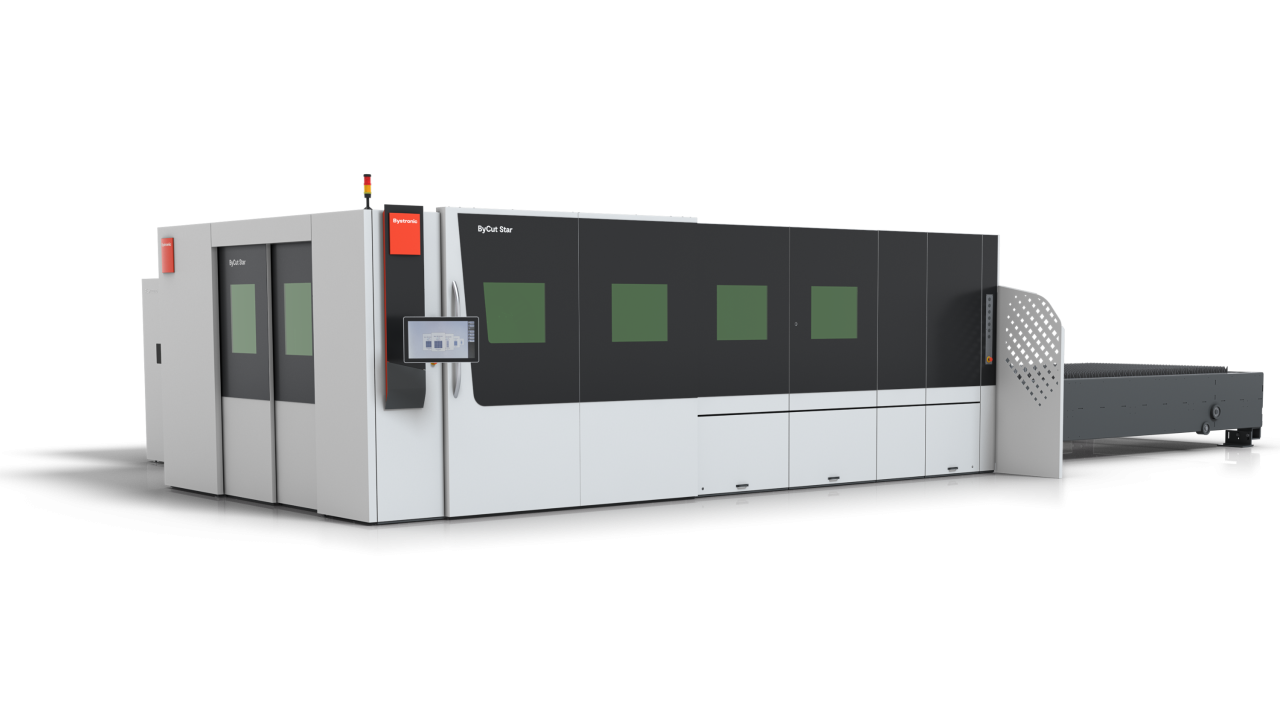

ByCut Star The smart fiber laser cutting machine

Fast & intelligent The new ByCut Star fiber laser cutting machine

ByCut Star 3015: Compact, with high power. Use it to cut sheet metal up to 3 x 1.5 meters with speed and precision.

ByCut Star 4020: Even more sheet metal, even more productivity. With the same high laser power, but for larger sheet metal, additionally increase your output.

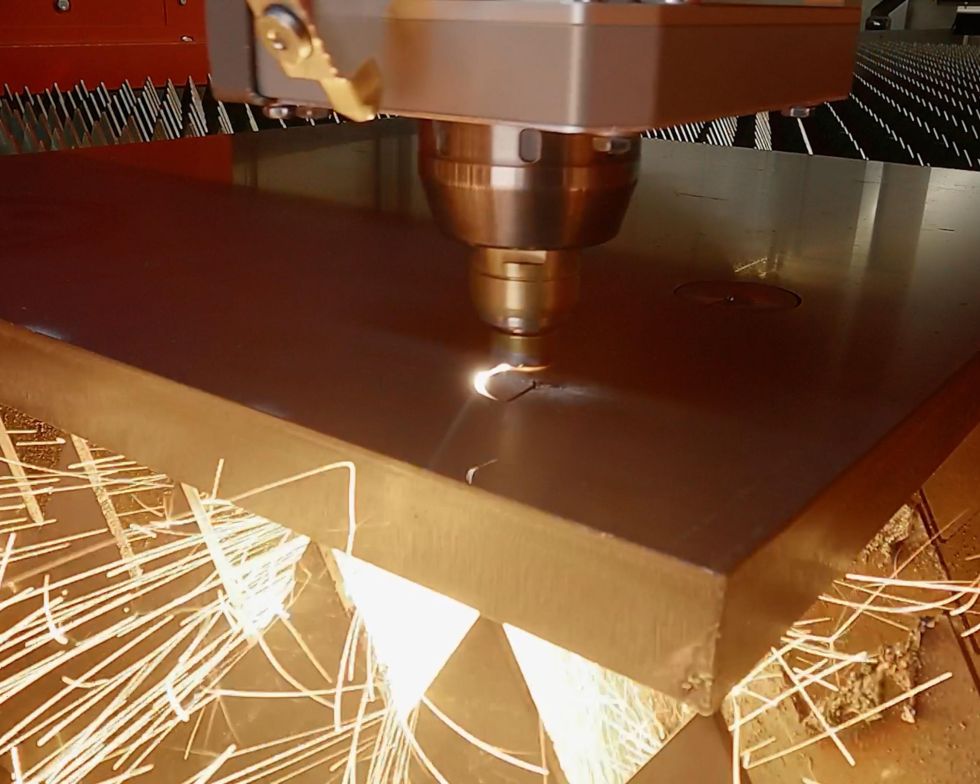

High cutting speed, an intelligent cutting process, and a new design – this is how the ByCut Star presents itself. The machine provides even better quality with an optimized cutting process and cuts the following materials precisely and reliably:

- Steel

- Aluminum

- Stainless steel

- Brass

- Copper

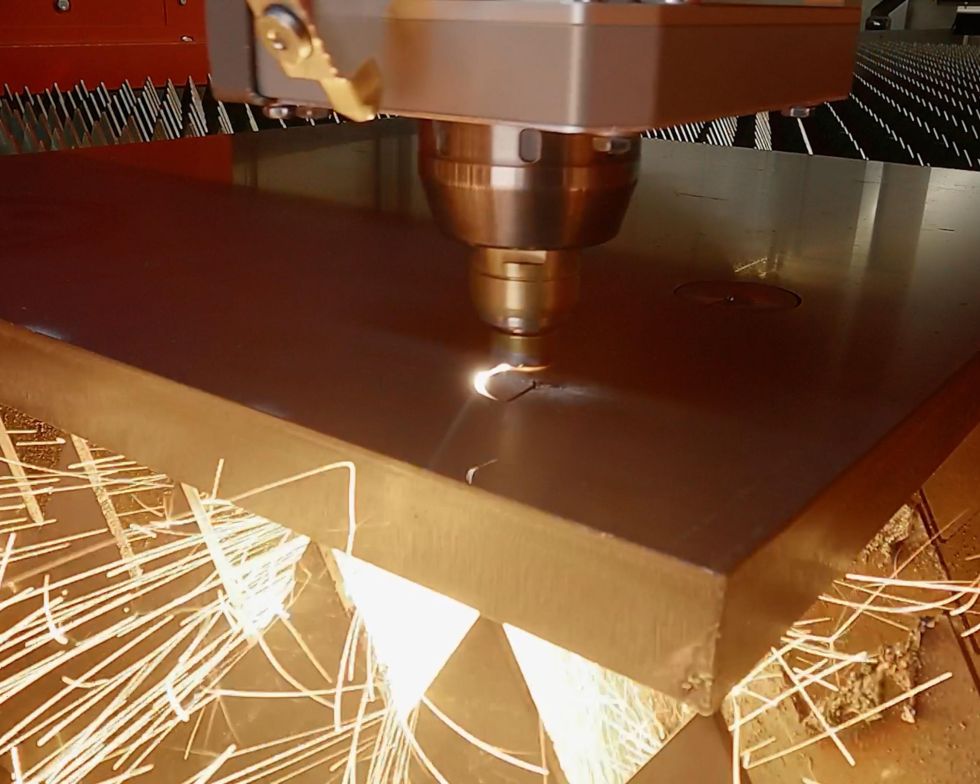

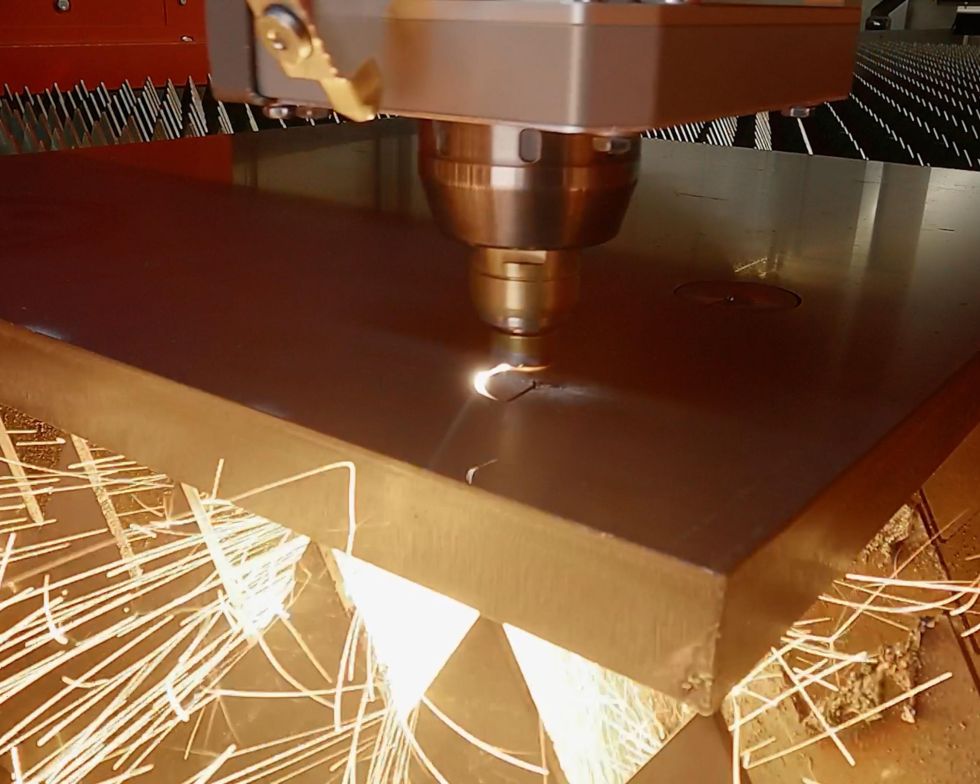

30 kW of laser power Shift into a higher gear now

Our ByCut Star provides up to 30 kilowatts of laser power. You can cut mild steel with sheet thicknesses between 6 mm and 15 mm twice as fast as cutting with 15 kW and MixGas. From 20 mm, the speed more than doubles. Shorter piercing times for sheet thicknesses from 15 mm additionally accelerate the process.

Smart functions Power is nothing without intelligence

Give your cutting process additional drive with smart functions such as:

- Intelligent Cutting Process (ICP): This is a new function in which a coaxial camera films through the nozzle of the machine. Thus, it gives you direct insights into the cutting process.

- Parameter Wizard: This option determines the perfect parameters for steel from 4 to 15 mm with N2 and MixGas within a few minutes.

This way you optimize your entire cutting process. You save valuable time and additionally accelerate your production.

It couldn't be simpler Work is a breeze with our ByCut Star

Operating the BySoft Cell Control Cut software using the 21.5-inch touch screen is as easy as using your smartphone. Even operators with little experience immediately get the hang of the software.

Fast & intelligent The new ByCut Star fiber laser cutting machine

ByCut Star 3015: Compact, with high power. Use it to cut sheet metal up to 3 x 1.5 meters with speed and precision.

ByCut Star 4020: Even more sheet metal, even more productivity. With the same high laser power, but for larger sheet metal, additionally increase your output.

High cutting speed, an intelligent cutting process, and a new design – this is how the ByCut Star presents itself. The machine provides even better quality with an optimized cutting process and cuts the following materials precisely and reliably:

- Steel

- Aluminum

- Stainless steel

- Brass

- Copper

30 kW of laser power Shift into a higher gear now

Our ByCut Star provides up to 30 kilowatts of laser power. You can cut mild steel with sheet thicknesses between 6 mm and 15 mm twice as fast as cutting with 15 kW and MixGas. From 20 mm, the speed more than doubles. Shorter piercing times for sheet thicknesses from 15 mm additionally accelerate the process.

Smart functions Power is nothing without intelligence

Give your cutting process additional drive with smart functions such as:

- Intelligent Cutting Process (ICP): This is a new function in which a coaxial camera films through the nozzle of the machine. Thus, it gives you direct insights into the cutting process.

- Parameter Wizard: This option determines the perfect parameters for steel from 4 to 15 mm with N2 and MixGas within a few minutes.

This way you optimize your entire cutting process. You save valuable time and additionally accelerate your production.

It couldn't be simpler Work is a breeze with our ByCut Star

Operating the BySoft Cell Control Cut software using the 21.5-inch touch screen is as easy as using your smartphone. Even operators with little experience immediately get the hang of the software.

Accelerate your production with our ByCut Star.

Technical specifications All information on the ByCut Star

| ByCut Star | 3015 | 4020 |

| Nominal sheet size | 3000 x 1500 mm | 4000 x 2000 mm |

| Maximum simultaneous positioning speed | 170 m/min | 170 m/min |

| Maximum workpiece weight | 1550 kg | 1900 kg |

| BySoft Cell Control Cut operation and manual control unit | | |

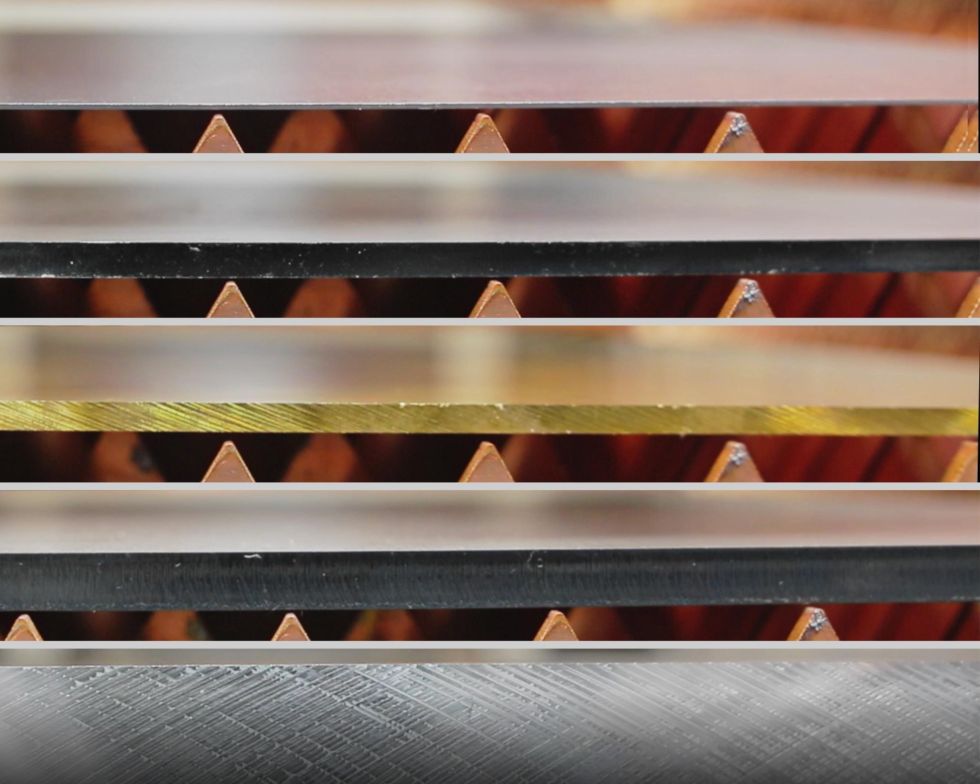

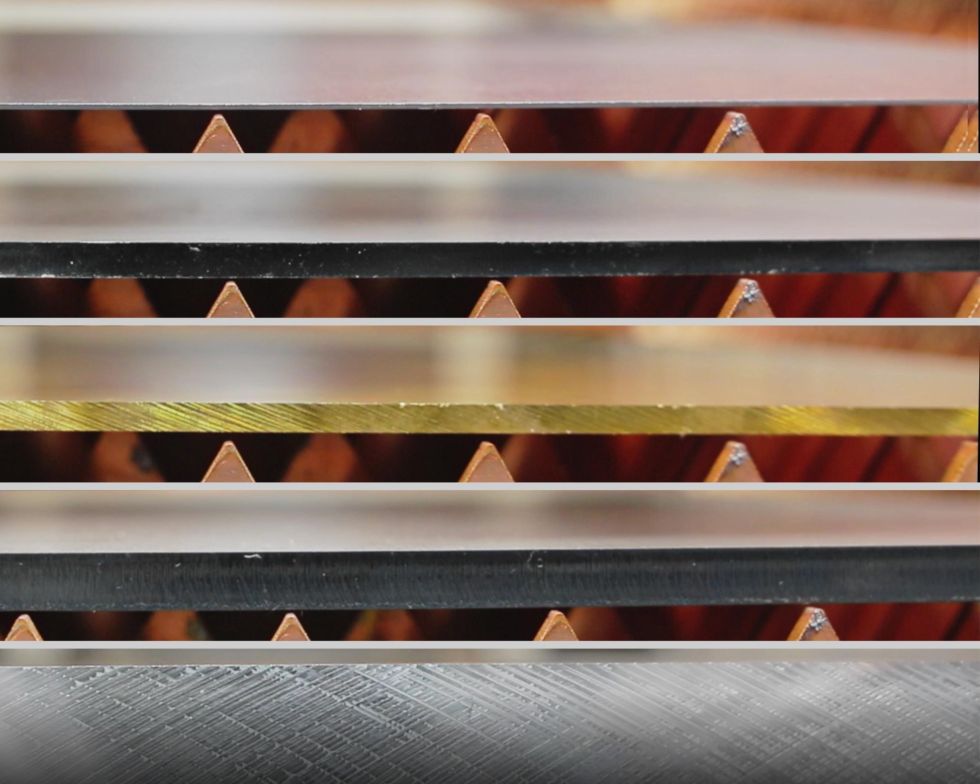

Bystronic MixGas Laser cutting with nitrogen & oxygen

Laser cut with laser mix gas from Bystronic to achieve clean cuts and minimal burr. Our unique blend of nitrogen and oxygen provides a distinct advantage over fusion and flame cutting.

Transform your production process and profit from enhanced cutting quality at higher speeds. Achieve superior high-quality parts even with low-quality material. Bystronic MixGas can easily be added to your existing laser system.

Features & options

-

Productivity & Efficiency -

Quality -

Flexibility -

Simplicity -

Future Fit -

Peace of Mind -

Business Success

High Laser Power

A high laser power increases productivity, improves cutting quality, and allows even thicker sheet metal to be machined economically. An essential component for high-power cutting is the right cutting head.

Intelligent Cutting Process

Increase your productivity: The cutting process is stable thanks to comprehensive process monitoring.

Cutting Head / Protective Glass

Precision & speed – using the Bystronic cutting head, you can machine thin and thick materials with the highest quality. The integrated changing system also allows fast maintenance of the protective glass.

MixGas

With a mixture of nitrogen and oxygen, we combine the benefits of each cutting method. Excellent cutting quality, as with pure oxygen, combined with the high cutting speeds of pure nitrogen.

Parameter Wizard

Use the Parameter Wizard to determine the optimum cutting parameters in a matter of minutes and achieve a lower cost per unit.

NCT & KerfScan

The Nozzle Control Tool (NCT) makes it possible to center nozzles quickly and reliably, as well as monitor the nozzle state. KerfScan checks the cutting process when flame cutting steel, detects problems, and solves them. This ensures a stable process without operator interaction.

BeamShaper

The manual or automatic BeamShaper in the cutting head helps when the material quality is poor. Improves cutting quality and increases process stability when cutting medium and thick mild steel.

ByPos Fiber

ByPos Fiber automatically sets the focus position according to the material and its thickness. The focus position is optimally matched to the process.

Spot Control

Depending on the sheet thickness and the material, Spot Control automatically adapts the focal point to it.

Detection Eye

More precision: Using a camera system on the cutting bridge, Detection Eye recognizes the exact position of the inserted sheet metal in a matter of seconds and supports the operator during the preparation for cutting.

Automatic Nozzle Changer

High process reliability and low preparation time – in just 15 seconds, the fiber laser changes nozzles based on the cutting plan. Less effort for more productivity.

HMI / Cutting Plan Editor

Copy, delete, rotate, move, and add – the editor makes it possible to adapt the existing cutting plan in just a few steps.

Machine Size

The right size for every material and application – you can get our machines in various sizes.

HMI / Cutting Plan Editor

As easy to operate as a smartphone. The intuitive HMI makes it easier to operate the machine, thereby increasing productivity

Automatic Nozzle Changer

High process reliability and low preparation time – in just 15 seconds, the fiber laser changes nozzles based on the cutting plan. Less effort for more productivity.

Detection Eye

More precision: Using a camera system on the cutting bridge, Detection Eye recognizes the exact position of the inserted sheet metal in a matter of seconds and supports the operator during the preparation for cutting.

Parameter Wizard

Use the Parameter Wizard to determine the optimum cutting parameters in a matter of minutes and achieve a lower cost per unit.

HMI / Cutting Plan Editor

The editor makes it possible to adapt the existing cutting plan in just a few steps.

Preparation for N2-Generator

Stay independent of gas suppliers – for a consistent gas supply and cutting quality.

Tilt Prevention

The software function prevents collisions with tipped parts and supports the automatic sorting process. The cutting plan is optimized to prevent tipping of cut parts.

Cut Control Fiber

The integrated sensor in the Cut Control Fiber makes it possible to interrupt the cutting process in case of cutting problems. Other functions make it possible to handle the material to be cut and the machine responsibly. These include process monitoring during cutting with nitrogen, monitoring the piercing process, or recognizing the exact position of the sheet edges.

Intelligent Cutting Process

Increase your productivity: The cutting process is stable thanks to comprehensive process monitoring.

NCT & KerfScan

The Nozzle Control Tool (NCT) makes it possible to center nozzles quickly and reliably, as well as monitor the nozzle state. KerfScan checks the cutting process when flame cutting steel, detects problems, and solves them. This ensures a stable process without operator interaction.

MixGas

With a mixture of nitrogen and oxygen, we combine the benefits of each cutting method. Example: You improve cutting quality when cutting thicker steel.

HP Shop Air

With this function, you achieve a lower cost per part and cut sheet thicknesses of 3 mm to 30 mm with compressed air.

Preparation for N2-Generator

Stay independent of gas suppliers – for a consistent gas supply and cutting quality.

High Laser Power

A high laser power increases productivity, improves cutting quality, and allows even thicker sheet metal to be machined economically. An essential component for high-power cutting is the right cutting head.

Intelligent Cutting Process

Increase your productivity: The cutting process is stable thanks to comprehensive process monitoring.

Cutting Head / Protective Glass

Precision & speed – using the Bystronic cutting head, you can machine thin and thick materials with the highest quality. The integrated changing system also allows fast maintenance of the protective glass.

MixGas

With a mixture of nitrogen and oxygen, we combine the benefits of each cutting method. Excellent cutting quality, as with pure oxygen, combined with the high cutting speeds of pure nitrogen.

Parameter Wizard

Use the Parameter Wizard to determine the optimum cutting parameters in a matter of minutes and achieve a lower cost per unit.

NCT & KerfScan

The Nozzle Control Tool (NCT) makes it possible to center nozzles quickly and reliably, as well as monitor the nozzle state. KerfScan checks the cutting process when flame cutting steel, detects problems, and solves them. This ensures a stable process without operator interaction.

BeamShaper

The manual or automatic BeamShaper in the cutting head helps when the material quality is poor. Improves cutting quality and increases process stability when cutting medium and thick mild steel.

ByPos Fiber

ByPos Fiber automatically sets the focus position according to the material and its thickness. The focus position is optimally matched to the process.

Spot Control

Depending on the sheet thickness and the material, Spot Control automatically adapts the focal point to it.

Detection Eye

More precision: Using a camera system on the cutting bridge, Detection Eye recognizes the exact position of the inserted sheet metal in a matter of seconds and supports the operator during the preparation for cutting.

Automatic Nozzle Changer

High process reliability and low preparation time – in just 15 seconds, the fiber laser changes nozzles based on the cutting plan. Less effort for more productivity.

HMI / Cutting Plan Editor

Copy, delete, rotate, move, and add – the editor makes it possible to adapt the existing cutting plan in just a few steps.

Machine Size

The right size for every material and application – you can get our machines in various sizes.

HMI / Cutting Plan Editor

As easy to operate as a smartphone. The intuitive HMI makes it easier to operate the machine, thereby increasing productivity

Automatic Nozzle Changer

High process reliability and low preparation time – in just 15 seconds, the fiber laser changes nozzles based on the cutting plan. Less effort for more productivity.

Detection Eye

More precision: Using a camera system on the cutting bridge, Detection Eye recognizes the exact position of the inserted sheet metal in a matter of seconds and supports the operator during the preparation for cutting.

Parameter Wizard

Use the Parameter Wizard to determine the optimum cutting parameters in a matter of minutes and achieve a lower cost per unit.

HMI / Cutting Plan Editor

The editor makes it possible to adapt the existing cutting plan in just a few steps.

Preparation for N2-Generator

Stay independent of gas suppliers – for a consistent gas supply and cutting quality.

Tilt Prevention

The software function prevents collisions with tipped parts and supports the automatic sorting process. The cutting plan is optimized to prevent tipping of cut parts.

Cut Control Fiber

The integrated sensor in the Cut Control Fiber makes it possible to interrupt the cutting process in case of cutting problems. Other functions make it possible to handle the material to be cut and the machine responsibly. These include process monitoring during cutting with nitrogen, monitoring the piercing process, or recognizing the exact position of the sheet edges.

Intelligent Cutting Process

Increase your productivity: The cutting process is stable thanks to comprehensive process monitoring.

NCT & KerfScan

The Nozzle Control Tool (NCT) makes it possible to center nozzles quickly and reliably, as well as monitor the nozzle state. KerfScan checks the cutting process when flame cutting steel, detects problems, and solves them. This ensures a stable process without operator interaction.

MixGas

With a mixture of nitrogen and oxygen, we combine the benefits of each cutting method. Example: You improve cutting quality when cutting thicker steel.

HP Shop Air

With this function, you achieve a lower cost per part and cut sheet thicknesses of 3 mm to 30 mm with compressed air.

Preparation for N2-Generator

Stay independent of gas suppliers – for a consistent gas supply and cutting quality.

Our fiber laser cutting machine experts are happy to support you.

Videos ByCut Star

Highlights from the video

Fast configuration

With the Parameter Wizard option, determine the perfect parameters for steel from 4 to 15 mm – using N2 and MixGas. Your fiber laser cutting machine will have the perfect parameters within minutes.

Broad spectrum

Be it mild steel, stainless steel, aluminum, or non-ferrous metal – the production spectrum is broad, and you can process sheet thicknesses of up to 50 mm (excluding non-ferrous metal).

High process reliability

Bystronic's automation solutions guarantee optimal utilization and maximum reliability in lightly-manned operations.

Easy operation

Operating the BySoft Cell Control Cut software using the 21.5-inch touch screen is as easy as using your smartphone.

Video tutorials

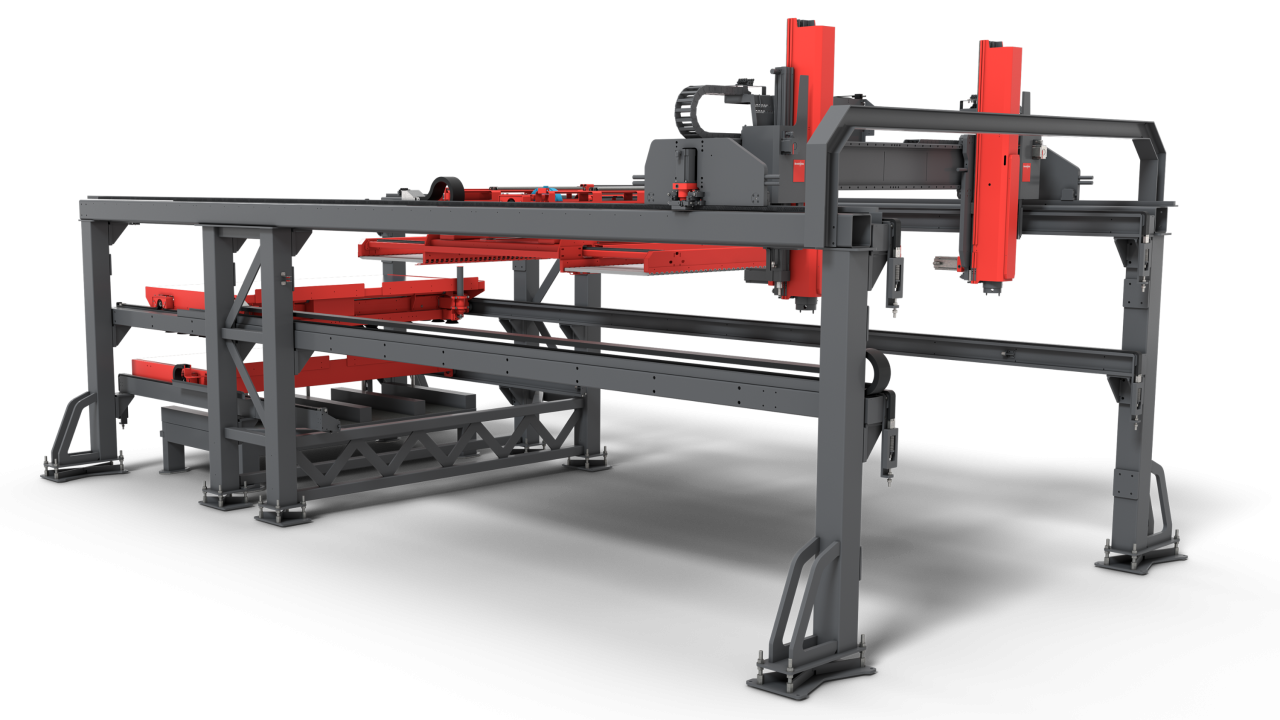

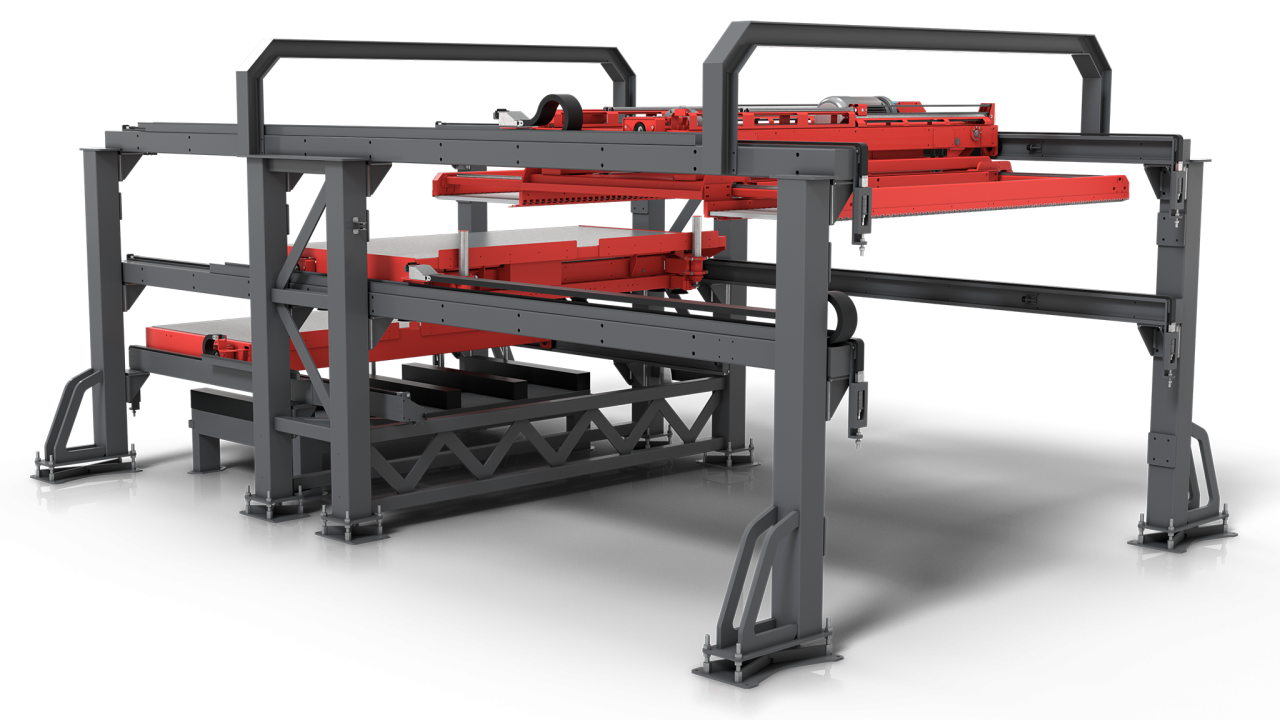

Advantage with automation The right solution for your fiber laser cutting machine

With the right automation from Bystronic, you increase the material flow of the ByCut Star. With the help of the loading and unloading systems, the laser cutting installation organizes the material flow fully or semi-automatically depending on the order. It also offers the option of processing small orders manually.

Bystronic Service Tailor-made for your needs and smooth production

ByCare packages

Our trained service experts ensure efficient production processes and safety for your employees. Depending on the requirements, we offer packages with basic to all-around services.

360° Customer Advisor

We analyze your production and determine your strengths and weaknesses. Based on this information, you can optimize processes and decrease downtime.

Our services

We maintain and repair your Bystronic systems. Optionally, you can obtain upgrades to retrofit your system or accessories to fine-tune your solution. Upon request, we can also perform a general overhaul.

Our service experts are always there for you – quickly and in person

Software for your fiber laser cutting machine BySoft Cell Control Cut: Easy and intuitive

The BySoft Cell Control Cut software makes controlling your machine and its associated automation easier for you. Thanks to the 21.5-inch touch screen, it's as simple as using your smartphone. No need to fiddle around for the right settings anymore. Large icons, short navigation paths, and help functions make our software so unique.

You are left with more time for the essentials.