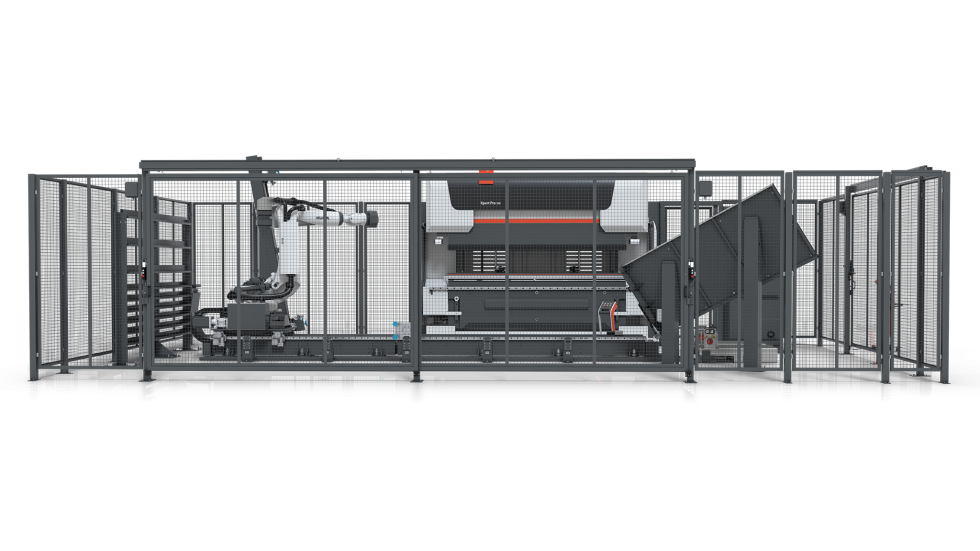

Xpert Pro Sheet metal bender for maximum performance

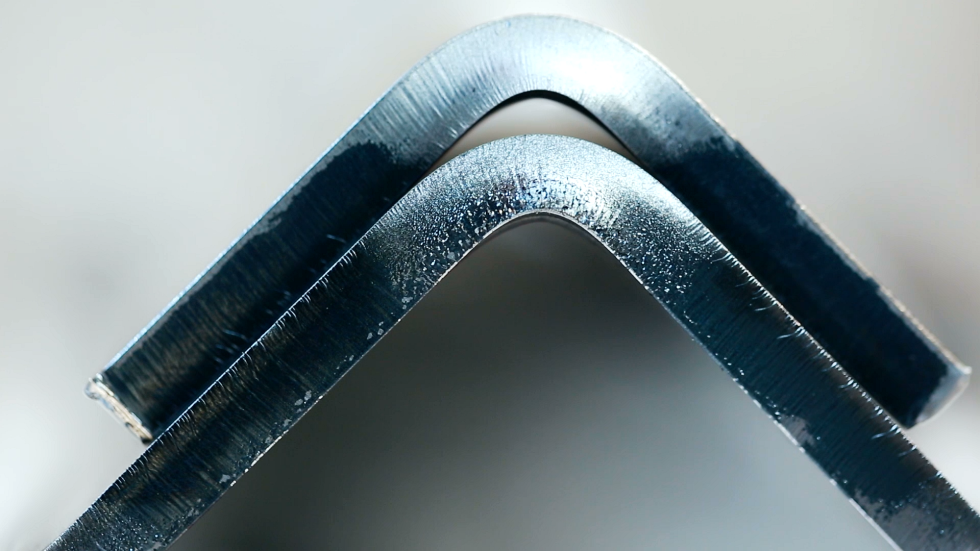

High-tech bending Trust in our quality

Whether simple or complex parts – with our sheet metal bender, the highest repetition accuracy is guaranteed. Dynamic crowning and our patented Pressure-Reference technology ensure consistent quality.

More bending in less time Get more out of your production

Bend faster than ever. Not only because the Xpert Pro works rapidly, but our sheet metal bender is also impressive when faced with high demands. Intelligent assistant functions and patented bending technology ensure consistently high quality – from the first to the last part of the order.

Fulfilling customer requests on time Sheet metal bender for complex processes

The Xpert Pro provides for the highest performance – even in the case of complex bending processes and varying materials. With the sheet metal bender, you even process workpieces of the most diverse strengths and qualities. You thus finalize your order faster and with greater flexibility.

Use the optimal configuration More time with the right sheet metal bender

You need a suitable machine for a specific sheet metal? Select the optimum press capacity from the broad power spectrum. Whether 100, 150, 200, 250 or 320 tons: With the perfect sheet metal bender, you have more time for the essentials.

High-tech bending Trust in our quality

Whether simple or complex parts – with our sheet metal bender, the highest repetition accuracy is guaranteed. Dynamic crowning and our patented Pressure-Reference technology ensure consistent quality.

More bending in less time Get more out of your production

Bend faster than ever. Not only because the Xpert Pro works rapidly, but our sheet metal bender is also impressive when faced with high demands. Intelligent assistant functions and patented bending technology ensure consistently high quality – from the first to the last part of the order.

Fulfilling customer requests on time Sheet metal bender for complex processes

The Xpert Pro provides for the highest performance – even in the case of complex bending processes and varying materials. With the sheet metal bender, you even process workpieces of the most diverse strengths and qualities. You thus finalize your order faster and with greater flexibility.

Use the optimal configuration More time with the right sheet metal bender

You need a suitable machine for a specific sheet metal? Select the optimum press capacity from the broad power spectrum. Whether 100, 150, 200, 250 or 320 tons: With the perfect sheet metal bender, you have more time for the essentials.

Elevate your performance with the right sheet metal bender.

Technical specifications All information on the Xpert Pro

| Xpert Pro 100, 150, 200, 250, 320 | |

| Tonnage | 100 – 320 t |

| Bending length | 3100 – 4300 mm |

| Open height | 640, 840 mm |

| Standard stroke | 250, 450 mm |

| BySoft Cell Control Bend | |

Press brake tooling for sheet metal bender

Thanks to original tools, you use the full potential of your sheet metal bender. Bystronic bending tools (in various clamping types) are flexible and versatile. In this way you cover all your applications:

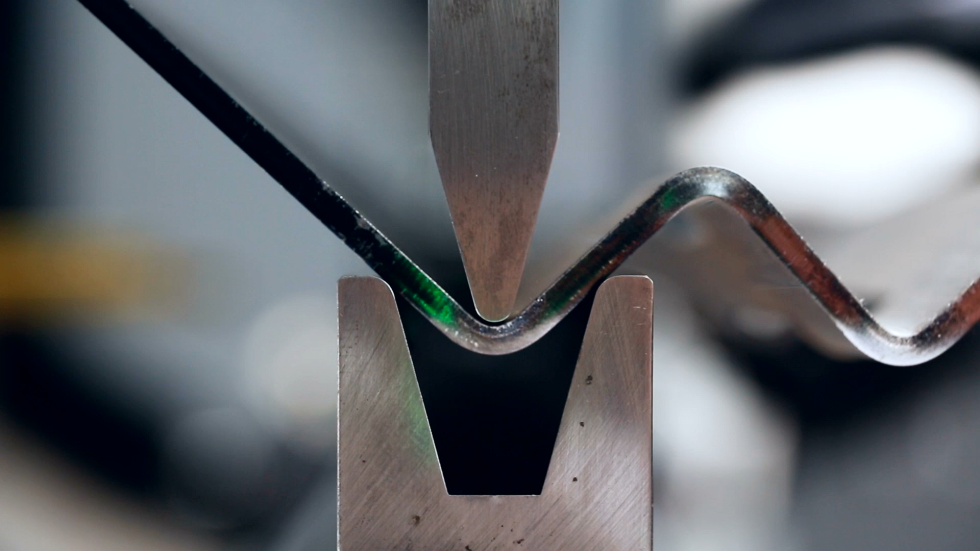

- Air bending

- Embossing

- 3-point bending

With the right tools you can achieve perfect bending results. We are happy to advise you on the design of individualized solutions for your products.

Our experts on sheet metal bender are happy to support you.

Features & options

-

Productivity & Efficiency -

Quality -

Flexibility -

Simplicity -

Future Fit -

Peace of Mind -

Business Success

Speed Options

Higher processing speed – with a selection between the Performance Edition and Dynamic Edition, choose higher speed compared to the Classic Edition.

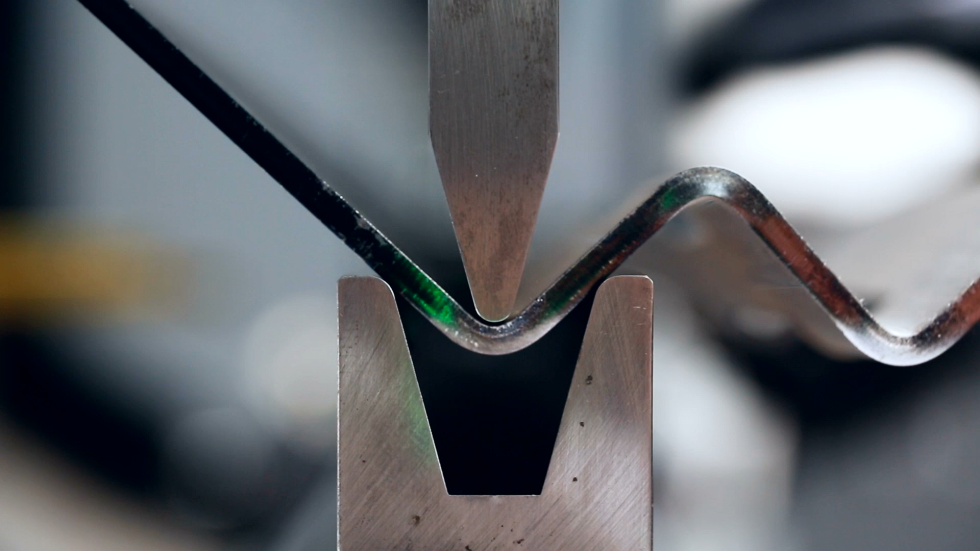

RFA clamping (Fast clamping System)

With the selection of hydraulic clamping systems, set-up time is reduced. Automatic tool alignment enables optimal and fast work.

Optical Bend Guiding System

Let us guide you – with our Optical Bend Guiding System, we direct you through the entire bending process.

Fast Bend +

For the best comfort and greater efficiency – with Fast Bend + we increase safety during work with our bending machines.

Dynamic crowning

The dynamic crowning system distinguishes itself with increased speed and short cycle times for the Xpert Pro.

LAMS

Outstanding bending accuracy – the optical laser- and camera-based angle measuring system uses sensors to support the bending accuracy of machines.

Optical Bend Guiding System

Let us guide you – with our Optical Bend Guiding System, you receive all the information about the entire bending process.

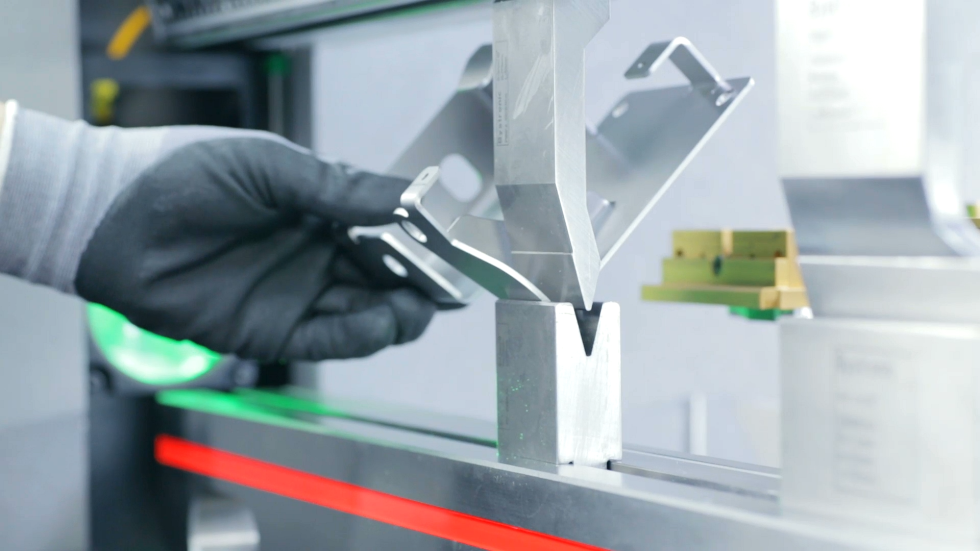

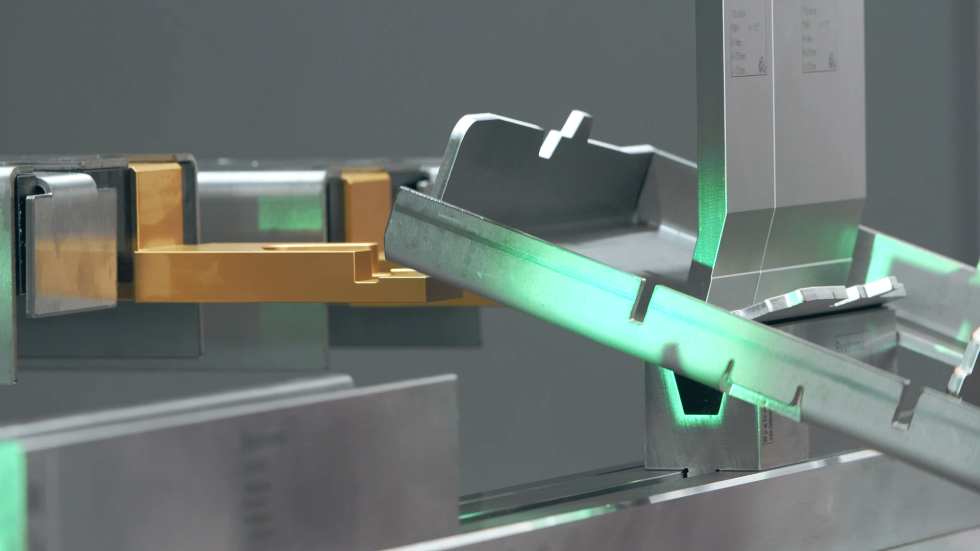

Automation ready Modular Tool Changer

Parking, moving, adding, removing, and integrated table cleaning enable more efficient work – even during unmanned operation.

Increased stroke and daylight

Extended stroke – for easier bending of narrow or high profiles and for multi-sided parts.

Multi axes back gauge

For more flexibility, the axes for the backgauge vary from 1 to 6 depending on the complexity of the product.

Dynamic Sheet Supports

Simple guidance of thin-gage material during the bending process – synchronized control between the bending aid and bending process.

Detachable Bending line laser

For all applications where the backgauge system is not suitable

ByVision Bending

The user interface is simple and intuitive in its operation.

Optical Bend Guiding System

With our Optical Bend Guiding System, you receive all the information about the entire bending process.

Fast Bend +

Fast Bend + increases safety while you work with our bending machines.

Multi axes back gauge

For simpler production, the axes for the backgauge vary from 1 to 6 depending on the complexity of the product.

Energy Saver HYBRID & SERVO (Energy & Noise reduction)

Our drive system is equipped with a special control system. This enables capacity according to need, increased speed, reduction of electric power consumption, and noise reduction

Automation ready

All our machines can be enhanced with automation solutions.

Optical tool detection

For shorter set-up times and increased safety

Automation ready Modular Tool Changer

Efficient work, even during unmanned operation, with the help of various functions such as parking, moving, adding, removing, and integrated table cleaning.

Dynamic crowning

With the dynamic crowning system for the Xpert Pro press brake, take advantage of increased speed and shorter cycle times.

LAMS

The optical laser- and camera-based angle measuring system uses sensors to support the bending accuracy of machines.

Automation ready

All our machines can be enhanced with automation solutions.

Energy Saver HYBRID & SERVO (Energy & Noise reduction)

Our drive system is equipped with a special control system. This enables capacity according to need, increased speed, reduction of electric power consumption, and noise reduction

Speed options

Higher processing speed – with a selection between the Performance Edition and Dynamic Edition, choose higher speed compared to the Classic Edition.

Increased stroke and daylight

Extended stroke – for easier bending of narrow or high profiles and for multi-sided parts.

Automation ready

Our machines can be enhanced with automation solutions.

Optical Bend Guiding System

All information at a glance – with our Optical Bend Guiding System, you receive all the information about the entire bending process.

Speed Options

Higher processing speed – with a selection between the Performance Edition and Dynamic Edition, choose higher speed compared to the Classic Edition.

RFA clamping (Fast clamping System)

With the selection of hydraulic clamping systems, set-up time is reduced. Automatic tool alignment enables optimal and fast work.

Optical Bend Guiding System

Let us guide you – with our Optical Bend Guiding System, we direct you through the entire bending process.

Fast Bend +

For the best comfort and greater efficiency – with Fast Bend + we increase safety during work with our bending machines.

Dynamic crowning

The dynamic crowning system distinguishes itself with increased speed and short cycle times for the Xpert Pro.

LAMS

Outstanding bending accuracy – the optical laser- and camera-based angle measuring system uses sensors to support the bending accuracy of machines.

Optical Bend Guiding System

Let us guide you – with our Optical Bend Guiding System, you receive all the information about the entire bending process.

Automation ready Modular Tool Changer

Parking, moving, adding, removing, and integrated table cleaning enable more efficient work – even during unmanned operation.

Increased stroke and daylight

Extended stroke – for easier bending of narrow or high profiles and for multi-sided parts.

Multi axes back gauge

For more flexibility, the axes for the backgauge vary from 1 to 6 depending on the complexity of the product.

Dynamic Sheet Supports

Simple guidance of thin-gage material during the bending process – synchronized control between the bending aid and bending process.

Detachable Bending line laser

For all applications where the backgauge system is not suitable

ByVision Bending

The user interface is simple and intuitive in its operation.

Optical Bend Guiding System

With our Optical Bend Guiding System, you receive all the information about the entire bending process.

Fast Bend +

Fast Bend + increases safety while you work with our bending machines.

Multi axes back gauge

For simpler production, the axes for the backgauge vary from 1 to 6 depending on the complexity of the product.

Energy Saver HYBRID & SERVO (Energy & Noise reduction)

Our drive system is equipped with a special control system. This enables capacity according to need, increased speed, reduction of electric power consumption, and noise reduction

Automation ready

All our machines can be enhanced with automation solutions.

Optical tool detection

For shorter set-up times and increased safety

Automation ready Modular Tool Changer

Efficient work, even during unmanned operation, with the help of various functions such as parking, moving, adding, removing, and integrated table cleaning.

Dynamic crowning

With the dynamic crowning system for the Xpert Pro press brake, take advantage of increased speed and shorter cycle times.

LAMS

The optical laser- and camera-based angle measuring system uses sensors to support the bending accuracy of machines.

Automation ready

All our machines can be enhanced with automation solutions.

Energy Saver HYBRID & SERVO (Energy & Noise reduction)

Our drive system is equipped with a special control system. This enables capacity according to need, increased speed, reduction of electric power consumption, and noise reduction

Speed options

Higher processing speed – with a selection between the Performance Edition and Dynamic Edition, choose higher speed compared to the Classic Edition.

Increased stroke and daylight

Extended stroke – for easier bending of narrow or high profiles and for multi-sided parts.

Automation ready

Our machines can be enhanced with automation solutions.

Optical Bend Guiding System

All information at a glance – with our Optical Bend Guiding System, you receive all the information about the entire bending process.

Videos Xpert Pro

Precision starting with the first part: The Xpert Pro saves your operators lengthy tinkering. Intelligent assistant functions such as the LAMS angle measuring system and the material curve generator take care of that.

Highlights from the video

Convenient offline programming of the bending jobs

Simply import the data from your sheet metal bender into BySoft Cell Control Bend without interrupting the production.

Original with bending data

The quality of our bending tools is matched and tested to Bystronic press brakes and your applications. So you get relevant import data for the software of your press brake for each tool.

Robust tools

The special manufacturing and the high-strength quenched and tempered steel of our bending tools guarantee a long service life even under tough conditions.

Consistent bend accuracy

Innovative mechanics deliver bends with the highest repetition accuracy. Our sheet metal benders are convincing thanks to intelligent functions, bending aids and optical bending process control.

Video tutorials

Made for automation Solutions for sheet metal bending machines

Increase your bending quality with the automation solutions for our sheet metal bender. There will be no programming effort for you. With the right automation solution, you can process a wide range of orders efficiently and without errors.

For example, by changing the bending tool fully automatically. This saves your employees time and allows them to devote themselves to more important tasks.

Bystronic Service Tailor-made for your needs and smooth production

ByCare packages

Our trained service experts ensure efficient production processes and safety for your employees. Depending on the requirements, we offer packages with basic to all-around services.

360° Customer Advisor

We analyze your production and determine your strengths and weaknesses. Based on this information, you can optimize processes and decrease downtime.

Our services

We maintain and repair your Bystronic systems. Optionally, you can obtain upgrades to retrofit your system or accessories to fine-tune your solution. Upon request, we can also perform a general overhaul.

Our service experts are always there for you – quickly and in person

Software for your sheet metal bender Easy to use

All process steps on one touch screen: Control your sheet metal bender intuitively and conveniently with BySoft Cell Control Bend. The intelligent software creates optimal bending processes and suggests appropriate tools for you.

Let the software do the work for you!