Bystronic MixGas High-speed production laser mix gas

High-quality results with uniquely blended laser mix gas

Bystronic MixGas is a game changer with its unique blend of nitrogen and oxygen. The laser mix gas provides a distinct advantage over other well-known types of laser cutting that use only nitrogen or only oxygen.

In comparison to flame and fusion cutting, Bystronic MixGas provides faster results even on low quality material. For example, 10 mm mild steel can be cut:

- up to 229% faster than oxygen cutting

- up to 109% faster than nitrogen cutting

Your benefits Laser cutting with Bystronic MixGas

Transform your production process laser cutting with nitrogen and oxygen.

Want to learn more about Bystronic laser mix gas?

Fast & cost-effective

Laser cut with laser mix gas from Bystronic to achieve an oxide-free and smooth surface. Speed up your production, as no oxide layers need to be removed before welding or painting.

It can be difficult to get good quality parts out of low-quality material. However, with our MixGas, you can reach the excellent process results you require.

Discover your advantages of laser cutting with mix gas for different materials:

Mild steel

Laser cutting of mild steel is the most used case in the industry. Minimum requirements are 10 Kw and cutting a minimum thickness of 8mm. For fusion cutting, the thickness of the material and the laser power are in relation to each other. For example, a 6 kW laser can cut up to 6 mm mild steel.

Aluminum

To laser cut aluminum, an expensive high-pressure compressor is usually required. This is only feasible if you are cutting large volumes of aluminum. If you’re looking for a solution to cut small amounts without a huge investment, use laser mix gas from Bystronic.

Achieve the same results without a compressor with an increased speed of up to 40%. Your parts will be ready more quickly with a smooth cutting edge and a reduced burr.

Let our specialists support you with their industry knowledge.

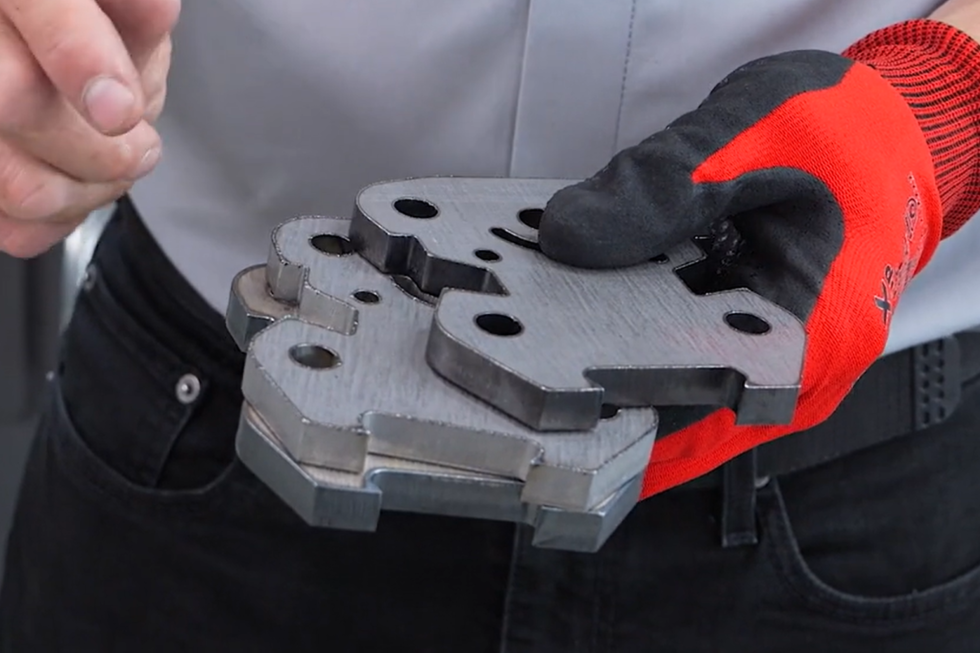

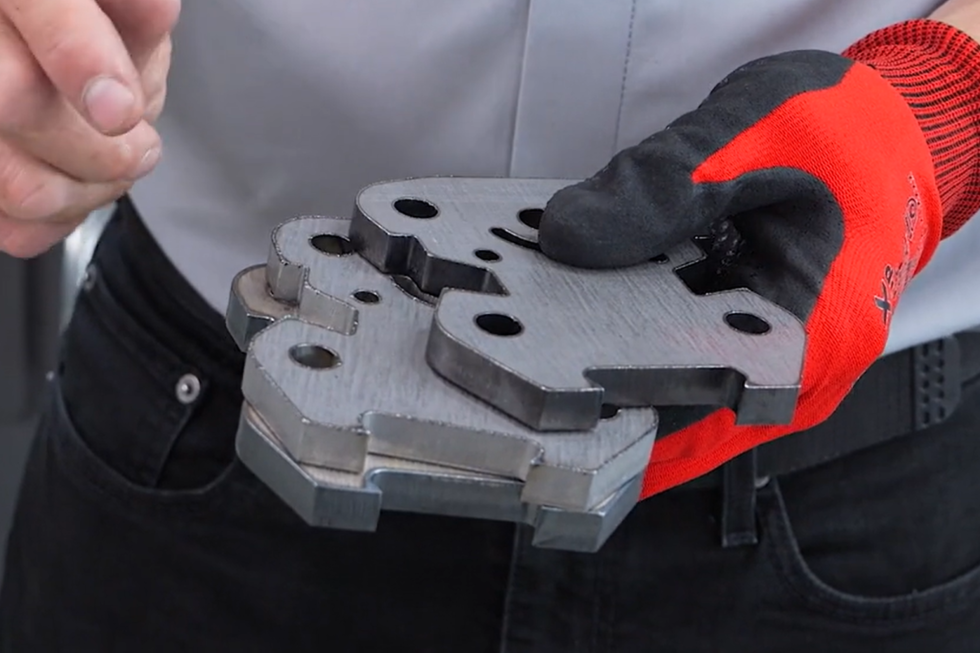

Material processing Laser mix gas applications explained

Our Senior Application Engineer Yves Burkhard shows you how to optimize your cutting processes and walks you through laser cutting various materials with nitrogen and oxygen.

Highlights from the video

Benefits in general

- Less slag

- Paint & powder coat ready

- Sharp edges

- Ready to weld parts

- Excellent results with poor steel quality

- Smaller holes and sharper contours

Benefits compared to O2 cutting

- 2 to 3 times faster cutting times

- Less oxidation compared to pure oxygen cutting and no or less additional post-processing step needed

- No danger of overheating the plate

- Smaller holes and sharper contours

Benefits compared to N2 cutting

- Slightly faster at mid-thickness group

- Much better cutting quality

- Reduction of post-processing (deburring) due to lower burr height

- Easier part removal vs. N2 due to less burr

FAQ

-

Does the ByStar Fiber need the newest SSC cutting head? Or is it possible with a V1 head? -

What gas pressures are required? -

What is the cost-comparison of these 3 different cutting processes? -

What are your recommendations on power ranges when using Bystronic MixGas? -

Will I have a benefit using MixGas when cutting Strenx 16.0 mm and 20.0 mm? -

Which thickness of aluminum should I use to achieve the best results with MixGas? -

What gas pressures work best for 16 mm, 20 mm, 25 mm, and 32 mm with 20 kW? -

What about stainless steel? -

Is the percentage of oxygen adjusted automatically by the machine or is it predetermined? -

What is the smallest hole in the most significant thickness? -

What is the price for a Bystronic NitrO2 Mixing machine? -

Since we have a Mix of nitrogen and oxygen, how do we estimate the gas consumption based on nitrogen? -

Can we get a private MixGas demo? -

Does this mean if I have a 4 kW fiber laser, I will not have an efficiency benefit with MixGas? -

Can older laser cutting machines also use MixGas? A BySprint for example? -

Will a Bystronic 6 kW, which cuts Strenx material be faster?

The minimum required is an SSC V2 laser head with the 3rd gas channel. For laser cutting with nitrogen and oxygen, we highly recommend the SSC V2.2. This cutting head can be installed during the MixGas installation if the machine does not have one.

A static pressure of 30 bar and a dynamic pressure of 25/27 depending on the model is recommended.

- Using oxygen, you will be able to cut 220% faster on average.

- Using nitrogen, you will be able to cut sharper edges and smaller holes while still being about 10% quicker.

- Use the savings for nitrogen as funds for post-processing.

- Our laser mix gas is weld and paint ready.

If you would like to have these parts sent to you, please get in touch with your local Bystronic service.

- For Aluminum, 3 kW to 20 kW.

- For Mild Steel, 10 kW to 30 kW.

That depends on your laser power. Overall, it's effortless to cut Strenx with laser mix gas.

We see the biggest benefit in terms of productivity in 12 mm. Although, a significant improvement in quality can be achieved in all thicknesses.

We mainly work around 5 bar.

We see positive results with stainless steel, but an oxidization occurs during the cutting process.

The percentage or ratio of the laser mix gas is in the parameter. The CNC gives the command to the mixer to adjust automatically.

Up to 15 mm, we guarantee 0,5x material thickness above 0,7x material thickness. But obviously, we are able to make a 2 mm hole in 30 mm.

If you are interested in receiving an offer, please get in touch us. They will be happy to support you.

Our skilled sales team can make a cost-consumption comparison for your machine and materials, but it's similar to the nitrogen consumption.

If you are interested in a demo or cost calculation with your parts, don't hesitate to get in touch us.

If you're cutting with aluminum, you will have a significant benefit. But if you're cutting steel, we recommend having at least a 10 KW machine.

No, the older generation of laser cutting machines does not have the needed cutting head or gas channels. We also recommend using laser mix gas with machines with 10 KW and higher when cutting mild steel.

Unfortunately no.

The minimum required is an SSC V2 laser head with the 3rd gas channel. For laser cutting with nitrogen and oxygen, we highly recommend the SSC V2.2. This cutting head can be installed during the MixGas installation if the machine does not have one.

A static pressure of 30 bar and a dynamic pressure of 25/27 depending on the model is recommended.

- Using oxygen, you will be able to cut 220% faster on average.

- Using nitrogen, you will be able to cut sharper edges and smaller holes while still being about 10% quicker.

- Use the savings for nitrogen as funds for post-processing.

- Our laser mix gas is weld and paint ready.

If you would like to have these parts sent to you, please get in touch with your local Bystronic service.

- For Aluminum, 3 kW to 20 kW.

- For Mild Steel, 10 kW to 30 kW.

That depends on your laser power. Overall, it's effortless to cut Strenx with laser mix gas.

We see the biggest benefit in terms of productivity in 12 mm. Although, a significant improvement in quality can be achieved in all thicknesses.

We mainly work around 5 bar.

We see positive results with stainless steel, but an oxidization occurs during the cutting process.

The percentage or ratio of the laser mix gas is in the parameter. The CNC gives the command to the mixer to adjust automatically.

Up to 15 mm, we guarantee 0,5x material thickness above 0,7x material thickness. But obviously, we are able to make a 2 mm hole in 30 mm.

If you are interested in receiving an offer, please get in touch us. They will be happy to support you.

Our skilled sales team can make a cost-consumption comparison for your machine and materials, but it's similar to the nitrogen consumption.

If you are interested in a demo or cost calculation with your parts, don't hesitate to get in touch us.

If you're cutting with aluminum, you will have a significant benefit. But if you're cutting steel, we recommend having at least a 10 KW machine.

No, the older generation of laser cutting machines does not have the needed cutting head or gas channels. We also recommend using laser mix gas with machines with 10 KW and higher when cutting mild steel.

Unfortunately no.