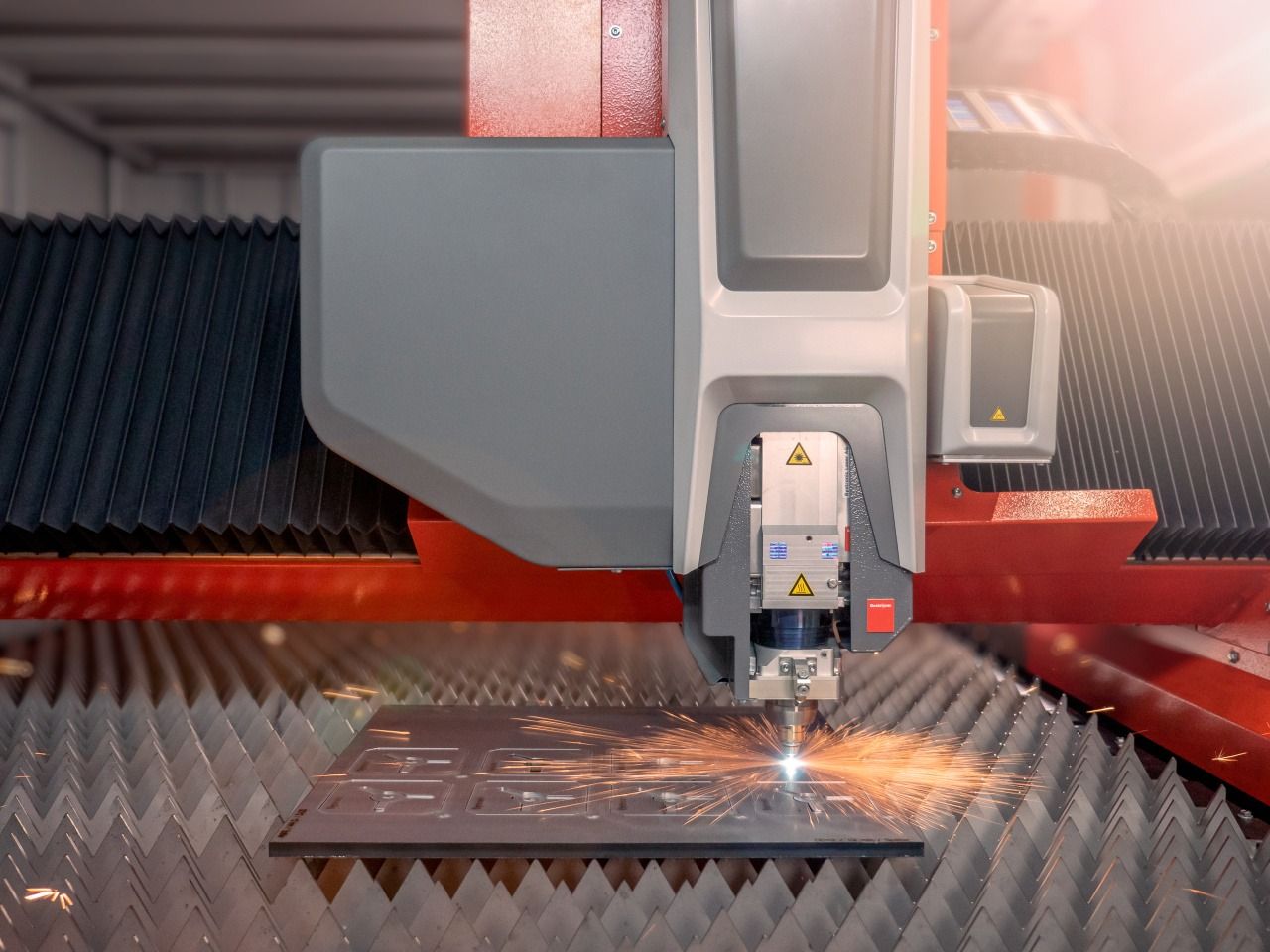

News How to Improve Fiber Laser Cutting Efficiency

To get the most from fiber laser cutting systems, it is essential to optimise cutting efficiency. This will ensure that cuts are accurate, precise and clean, without any risk of wear and tear or other issues. Along with regular maintenance, there are also other things that you can do to improve efficiency when working with fiber laser cutting systems.

Improving Fiber Laser Cutting Efficiency

Here are just a few of the ways that you can improve fiber laser cutting efficiency.

Idling

Idling or idle strike refers to the movement that takes place between two different points when the laser is not currently cutting. Decreasing idle time can greatly improve cutting efficiency. The way that idling is decreased is a method known as leapfrog. With this method, the laser jumps from one point to the next point, moving upwards and downwards as it jumps. Taking its name from the motion of a frog jumping, leapfrog ensures that lasers do not lag behind.

Laser focus

Laser focus has different requirements for laser settings, which will depend on the project and material. Being aware of the focus requirements is essential in order to use the correct laser setting. If the right setting is not used, you will not have the right focus. This, in turn, means that your cutting efficiency will be limited.

Bridge

During laser cutting, sheet metal is meant to be supported by a support strip. Parts removed during cutting will not fall between the gaps in this zigzag strip if they are not small enough. In the case of parts that are large enough to be supported, there is a risk of parts not balancing properly. This increases the risk of the cutting head making contact with cut-out parts, meaning that the machine will stop or the cutting head will be damaged. Using a bridge or micro-join cutting process will prevent this from happening, creating breaks in the closed contour and ensuring that cut-out parts are stuck with surrounding metal instead of falling.

Maintenance

Maintenance of laser cutters is essential. This will make sure that your machines work properly and efficiently. If routine maintenance is not done regularly, dust, debris and other particles can build up on the laser lens, leading to inaccurate cuts. Dust can also enter the machine, which can cause problems.

Using high-quality machines will also make a big difference in the efficiency of your work. To find out more about the Bystronic range of fiber laser cutting machines, contact us today.