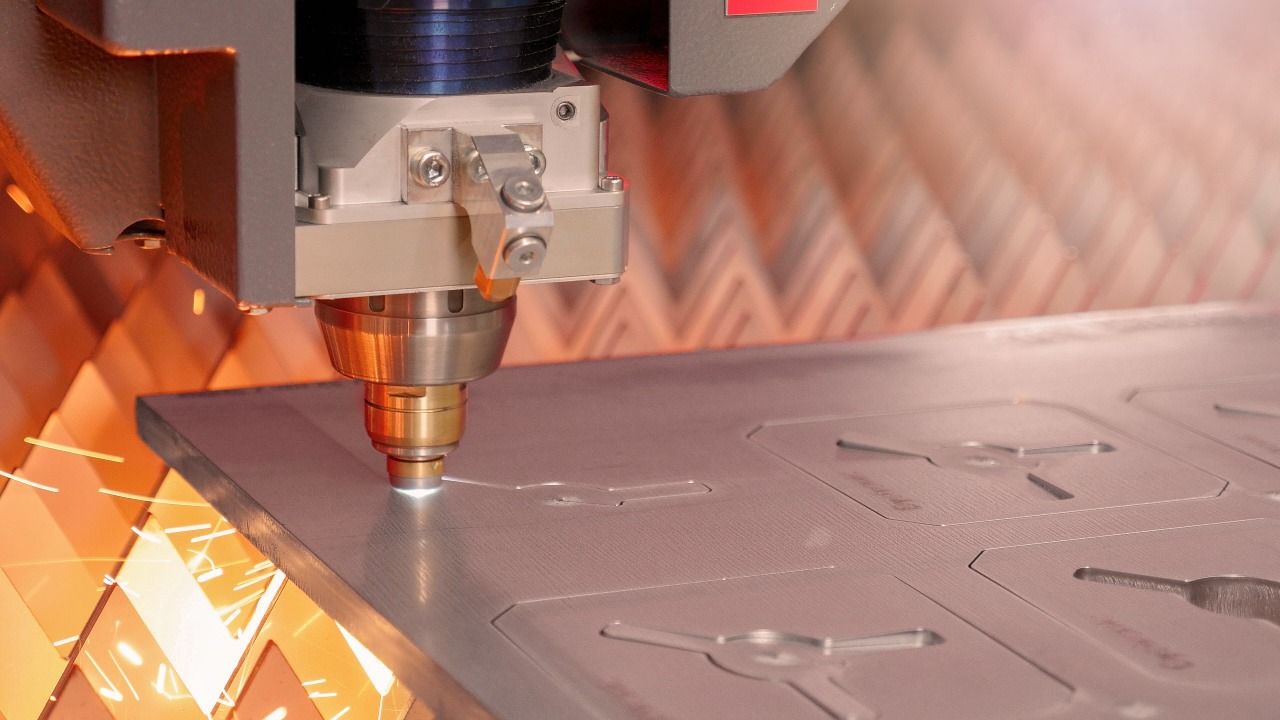

News How to Choose the Right Laser Cutting System

Choosing the right laser cutting system is essential to get the most from your tools. There are a number of factors that you will need to take into account. The first thing to consider is the type of laser cutter you require, which will be determined by the light source. Next, you will need to consider the power you require, which is determined by the thickness of the cut sheet metal. Finally, you will need to consider the cost performance, which comes down to the investment you make in the laser cutting system quality and lifespan.

Choosing the Right Laser Cutting System

Here are some things you will need to consider when choosing the right laser cutting system.

Light Source

The light source refers to the type of laser system. The main light sources include CO₂ and fiber. CO₂ uses gas to create a beam that cuts and engraves various materials. Fiber laser cutters are the most efficient, cost-effective and accurate systems. The laser beam is made by an active fiber and sent over a transport fiber to the machine cutting head. These lasers are much smaller than CO₂ lasers, generating a higher level of power from the same amount of current. Fiber cutting systems are mainly used for processing thin to thick sheet metal from steel, stainless steel, aluminium and non-ferrous metals such as copper and brass.

Power

The power of the cutting system is determined by the thickness of your sheet metal. The thicker the metal, the more power you will need. This is because it becomes much harder for lasers to cut through extremely thick metal sheets. When choosing equipment, make sure that it is able to cut through the metal you typically process. Equipment with multiple power options may not be used as often as those that cater specifically to your needs.

Cost Performance

One of the most important factors to consider is cost-efficiency. As with any equipment, paying a smaller amount for sub-quality cutting systems will end up costing you a lot more in the long run. These machines may not have a high power level. Parts may wear easily and need frequent replacement. Laser beams may not be precise, which can cause major problems in the production chain. It is always best to consider the bigger picture and invest in systems from trusted manufacturers to get full peace of mind knowing that your equipment will have the best performance and longevity.

Bystronic offers a range of premium systems to meet your budget and needs. Contact us today to find out more about our globally-recognised laser cutting systems.