Sheet metal processing industry Swiss quality sheet metal processing machines

For the sheet metal processing industry of the future

Sheet metal is close to our hearts. That is why Bystronic supports you in modern sheet metal processing.

We help you to optimize your production with laser cutting machines, tube lasers, press brakes, automation and suitable software.

Your advantages

- Save costs and reduce your CO2 emissions.

- Ensure more productivity and output.

- Benefit from unmanned and low-manpower production with automation.

Companies in the sheet metal processing industry have relied on us for quality, innovation, know-how and the Bystronic Service since 1986.

Smart machines

Maintain a stress-free overview of your production and quickly correct errors with customized software.

Highest performance

Process sheets of all thicknesses and sizes precisely and reliably, regardless of the material.

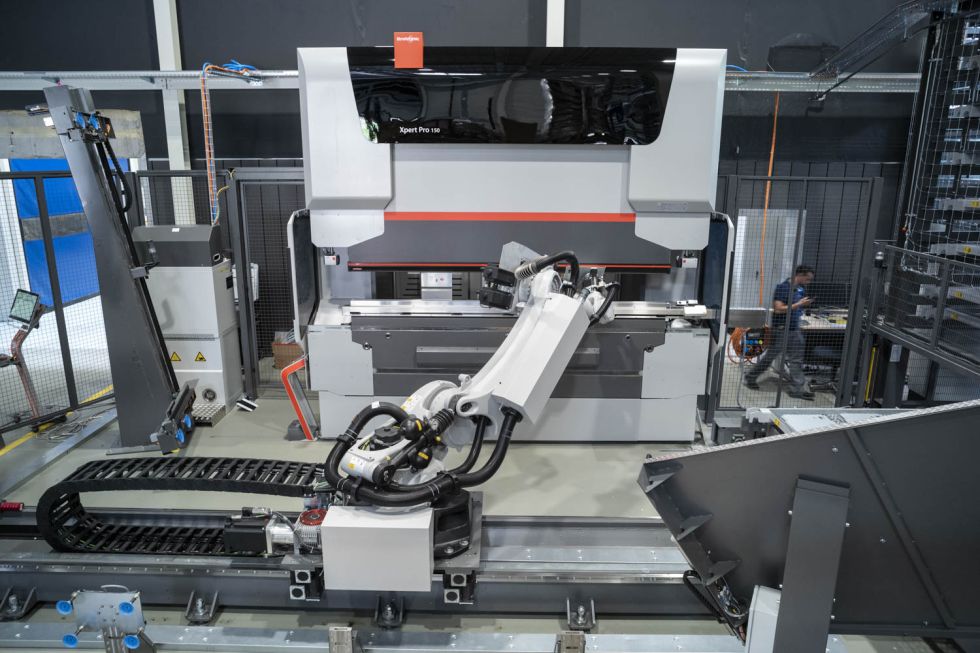

Automation ready

All our machines are ready for automation, from entry-level to high-performance models.

Do you have questions? We are experts in the sheet metal processing industry and help you achieve greater productivity.

How you can benefit from Bystronic

Be more productive

Do you want to increase your daily parts production? We have the systems and machines to assist you!

We optimize your processes and increase your production capacity so that you no longer have to worry about missing your customers´ deadlines.

Make the leap into the future with our fully or partially automated solutions. With our products and systems, you can produce quickly, efficiently and safely. We also provide training and support so that you can start using your new tools right away.

Reduce costs

A Bystronic fiber laser needs as much energy as two CO2 lasers. Thus, a change to our fiber lasers greatly reduces your energy costs.

With our high-quality system solutions, you also work precisely. This means you produce good parts faster saving material. Post-processing is not necessary.

Stay flexible

Say goodbye to worries about staff shortages. With the right solution, both unmanned production and a quick switch to manual processing are possible.

In addition, we train your employees intensively so that they become experts in your Bystronic machines.

All-round care

You can rely on our Bystronic Service. We offer high-performance system solutions and machines for beginners in the sheet metal processing industry with a small budget. All our models are also ready for automation. This means that all options are available to you.

We also assist you with financing.

Individual solutions for your requirements in the sheet metal processing industry

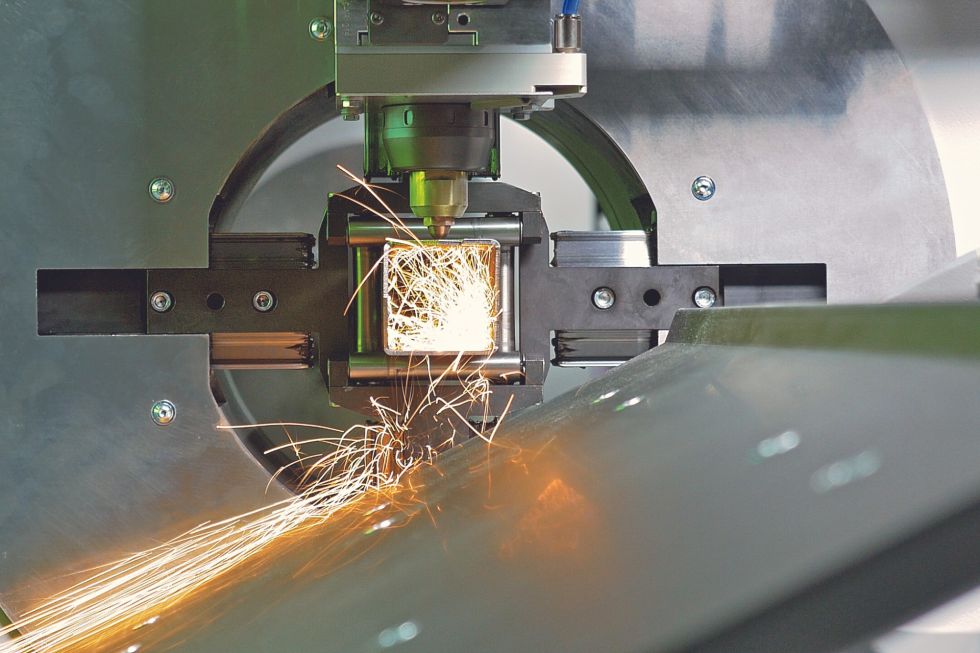

Laser cutting machines

Cut, among others, steel, aluminum, stainless steel, brass, titanium and copper sheets with our fiber lasers. Even with our entry-level model, you benefit from a powerful 15-kilowatt output.

Tube lasers

With 2D and 3D laser cutting technology, our high-end tube lasers precisely process a wide variety of materials and sizes. You also reduce power and maintenance costs.

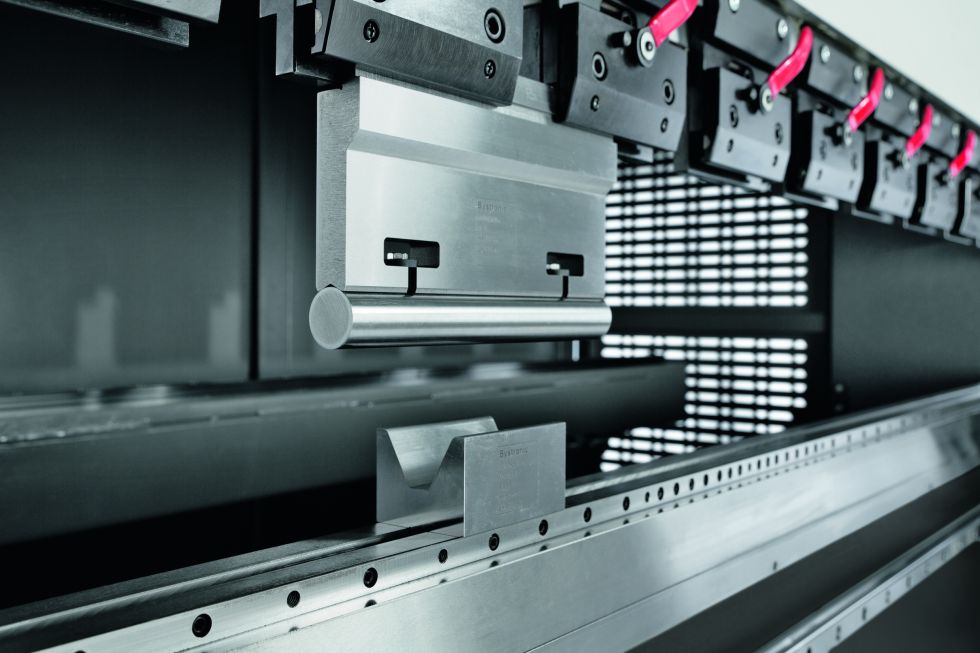

Press brakes

Our bending technology offers something for everyone: From an entry system to a high-performance press brake for complex bending processes.

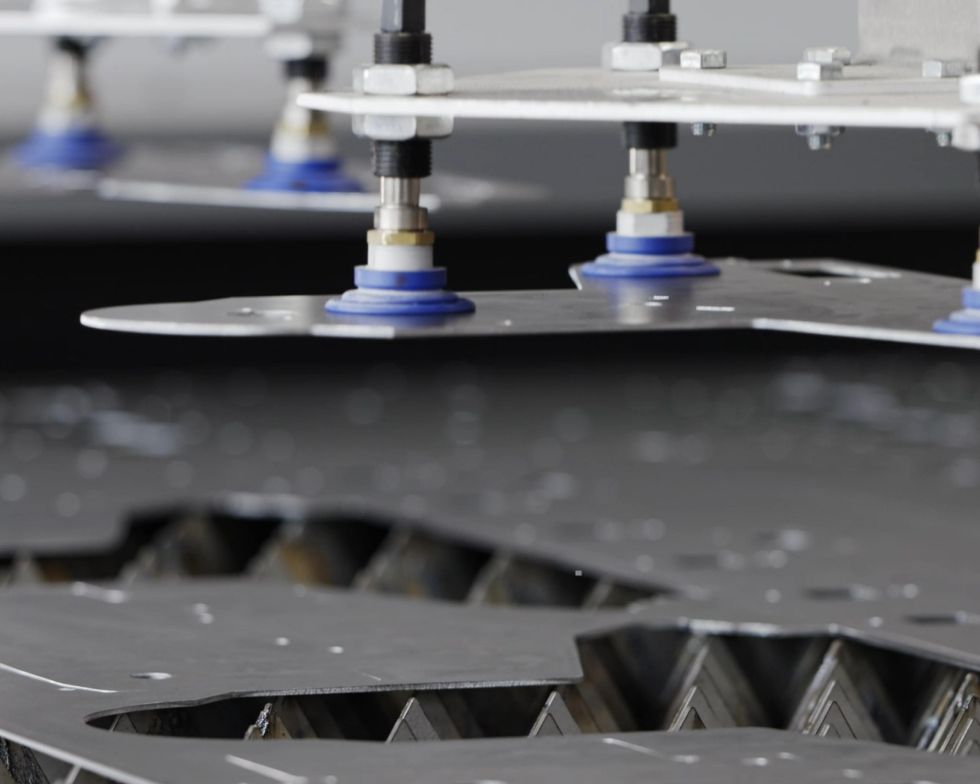

Laser automation

Experience a fully automatic sheet loading process with weight control at the elevator. When unloading the sheets, a check of the tilted parts takes place.

Ensure reliable automated production.

Would you like to learn more about individual products and how you can integrate them in your production? We are happy to assist you.

Important materials for the sheet metal processing industry

Bystronic machines process a wide range of materials:

- Steel

- Stainless steel

- Aluminum

- Copper

- Brass

- Titanium

This enables a wide range of products and applications in the sheet metal processing industry.

Get Bystronic as your partner. We advise you and take your company into the future of the sheet metal processing industry.

Our promise to you

Start the future with confidence - with Bystronic as a reliable partner at your side!

With flexible financing options and our Basic Care Package, including 360° Customer Advisor, you get a comprehensive production analysis for planning downtime.

Our upgradable and modular entry-level models offer the possibility of expansion at any time with upgrades such as new cutting heads, improved nozzles, safety and software solutions.