News Fabtech 2015: Cutting, Bending, Automation & Software Technology Innovations

The Fibernomics Advantage in Sheet Metal Fabrication

Realize the Fibernomics Advantage when you optimize the “Pull” and “Push” demands of the fabricating process with innovative technologies.

It is no longer how a single piece of machinery will affect the fabrication process, but how all the machines and supporting software technologies work together to create cohesive and effective fabrication business solutions.

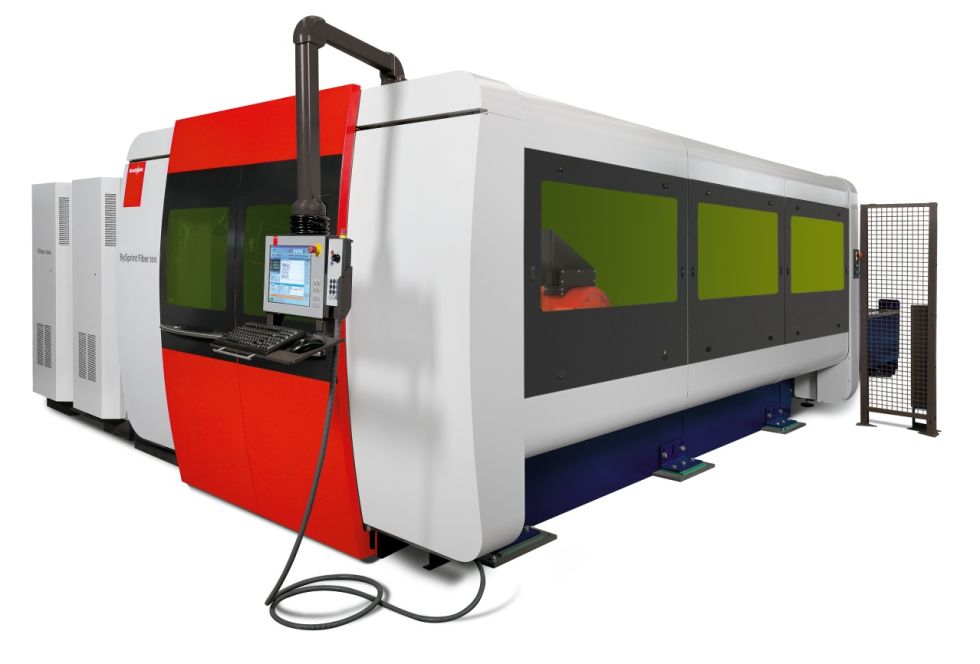

BySprint Fiber with ByTrans Extended: Setting New Standards for Speed, Productivity, Efficiency

Fibernomics begins with the powerful BySprint Fiber 3015 with 6kW Fiber laser which will be equipped with the optional ByTrans Extended high speed material automation -- a system that is setting new standards for speed and productivity across a wide range of materials and thicknesses. Equipped with the ByTrans Extended compact material handling system, the BySprint Fiber can generate highly productive and efficient job flows through higher machine utilization, expanded operations and reduced labor costs. ByTrans Extended incorporates two material cassettes which makes the machine system even more autonomous. It is designed not just for storage, but also for large parts removal as well as the preparation of plastic protective separators which are placed between the cut metal sheets by the system. Optimizing the material handling for both loading raw materials and unloading the cut sheets helps with the “pull” and “push” demands.

High Speed Bending: Optimizing the press brake and other downstream processes from the Fiber laser helps optimize the “push” demands of the fabricating process.

Xpert Press Brake: The Ultimate Bending Experience

With unique features like ByVision Bending control, Voice Control, Part ID and new Bystronic Tooling and Clamping Systems, the Bystronic Xpert 150 press brake offers unmatched efficiencies and productivity capabilities. With a comprehensive database of material bend angles and bend allowances, ByVision Bending control can make a bending professional of every user from the very first experience. Powerful and easy to operate, the Xpert 150 uses a full 22 inch HD touch screen to display realistic 3D part animations and software driven menu selections. The servo-hydraulic Xpert 150 press brake with dynamic press brake technology is the only press brake on the market that introduces no angle errors itself with a ram positioning accuracy of .00015-inch.

Introducing Xpert 40 Press Brake: Profits through Speed and Portability

Bystronic’s Xpert 40 compact, ultra-high speed ergonomic press brake is the fastest press brake of its size on the market. A 6-axis ultra-high performance back gauge and high speed ram enable the cost-efficient production of highly complex shapes and ensures the highest process efficiency to keep pace with high speed Fiber lasers . The Xpert 40 is the FIRST to offer integrated tool storage, greatly reducing non-productive bending times. Flexible tool selection and a press capacity up to 44 US tons makes possible a wide range of applications from thin and thicker materials. High operator efficiency is achieved through ergonomic design and individually adaptable work space. The process-controlled drive unit reduces power consumption by up to 30 percent.

Smart Choice and the Fibernomics Advantage

Introducing BySmart Fiber 3015: Bridging Performance with Lower Investment Costs

With the NEW BySmart fiber 3015 with Fiber 3000 watt laser, Bystronic is offering a high-quality performance package that enables first-time users a fast entry into laser cutting. Performance features include a highly dynamic drive system capable of high accelerations and high speeds as required by the fiber laser. The BySmart Fiber also features the high performance Bystronic ByVision control with full 22 inch HD touch screen and software driven menu selections, making it both easy to learn and easy to operate. The BySmart Fiber is equipped with an automatic shuttle table capable of allowing for the loading and unloading of materials on one table while the machine is cutting on the other table. The BySmart Fiber can also be fitted with a Fiber 2000 watt laser source for an even further reduction in the investment costs, while still maintaining the competitive advantages of faster speeds and lower operating costs that are synonymous with Fiber laser cutting.

Introducing Xact Smart: The Smart Choice in Performance Bending

The NEW Bystronic Xact Smart press brake features standard active hydraulic crowning capabilities that can deliver accurate bend angles across the entire bed length. Easy to set up and program, the Xact Smart combines high bend accuracy and advanced features into an affordable, high-value package. The new Xact Smart incorporates the powerful Bystronic ByVision Bending control system. The ByVision Bending interface uses a full 22 inch HD touch screen to display realistic 3D part animations and software driven menu selections capable of guiding operators through the step by step bending process as well as selecting bend sequences automatically. Programming is simple and intuitive. Designed for easy tool integration, this press brake can easily accommodate all types of punches and dies with the appropriate clamping system.

BySoft: Make It Easy

High-performance software is fundamental component of Fibernomics and modern sheet metal processing. BySoft 7 is a robust, easy to operate CAD/CAM software package that supports both 2D and 3D CAD and provides the user with an extensive array of process scheduling and monitoring functions. BySoft 7 employs a highly intuitive structure that enables first-time users to begin working with the software quickly and easily. It simplifies processes within the factory with advanced capabilities for nesting parts, creating cutting plans, generating bending programs, simulating bending sequences, and more. Actual production costs can be determined through an embedded cost calculator.

The BySoft 7 programming system with full ERP interface capabilities consists of four modules: Sheet Cutting, Tube Cutting, Bending, and Plant Manager Cutting . Plant Manager Cutting (PMC) is a unique operational tool that both plans and monitors manufacturing processes , including all laser and waterjet cutting operations. It compiles all relevant machine and production data and makes it continuously available to the operator, providing maximum transparency. This is’ real-time’ system integration and the most efficient way to ensure that your process remains consistent so that your costs and margins remain consistent.

Experience the Fibernomics Advantage during Fabtech at our Booth S919 in the South Hall where we offer continuous machine and software demonstrations. We also invite you to take a break and stop by the refreshment bar.

About Bystronic:

Bystronic Inc. has offered customers single source service expertise for over 35 years. They provide innovative laser cutting, waterjet cutting and press brake systems, system software and comprehensive customer training and support. The company’s North American headquarters is located in Elgin, IL. Offices are also located in Toronto, Canada and Guadalajara, Mexico.

For more information on Bystronic Inc., e-mail sales.us@bystronic.com or contact Frank Arteaga, Bystronic Inc. at 847-214-0300.