Intelligent sheet steel processing with Bystronic Machines, software and automation of the future

We process all types of steel More efficient cutting processes for more profit

Our machines at Bystronic make no distinction as to what type of steel is involved. We can process any type. Both large and small series are possible.

If required, our experts will work with you to develop an application tailored to your needs.

Do you have questions about sheet steel processing with Bystronic? We will be happy to help you.

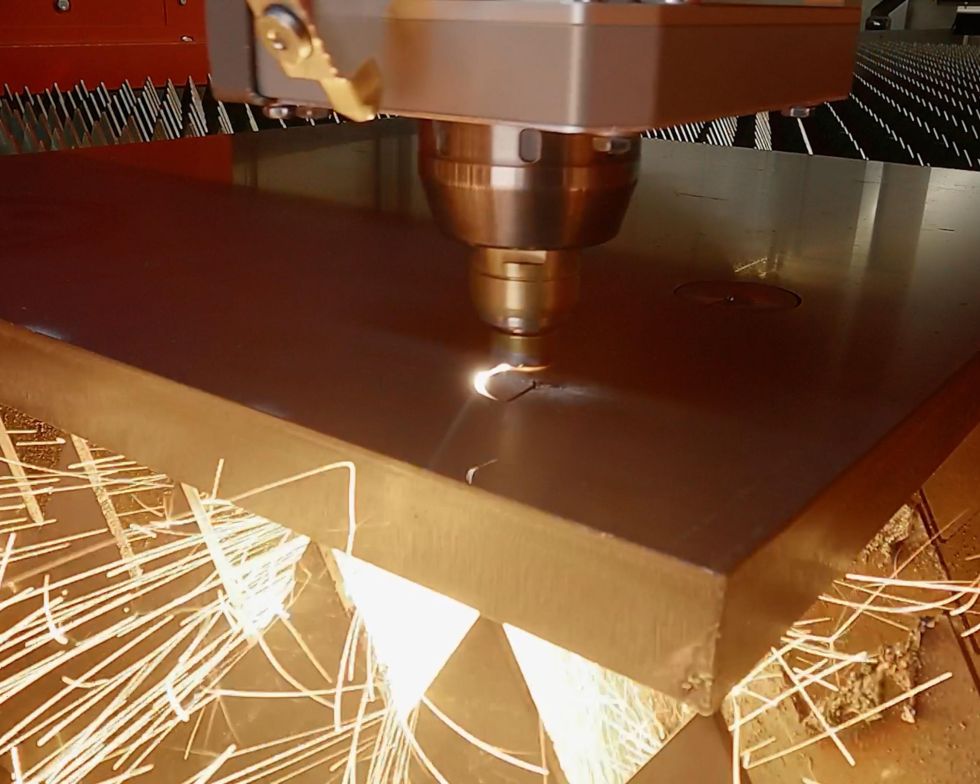

Sheet steel processing with laser cutting machines

Our laser cutting machines offer precise and reliable sheet steel processing thanks to their optimized cutting process. You benefit from an impressive cutting speed and an intelligent and innovative design.

With Bystronic you can cut sheet thicknesses from 0.8 - 30 mm. Selected models also allow 50 mm. The sheet dimensions that can be processed range from 3000 x 1500 mm to 12 x 2.5 m.

Rough or uneven surfaces can impair cutting quality. The surface quality of the steel must therefore be taken into consideration before the machining process. Our Smart Features support you in achieving the best results. You get precise results which you can rely on:

- Intelligent Cutting Process (ICP): This is a new function in which a coaxial camera films through the nozzle of the fiber laser. This gives you a direct insight into the cutting process.

- Parameter Wizard: This option determines the perfect parameters for steel from 4 to 15 mm with N2 and MixGas within a few minutes.

Tube processing with tube lasers

Accelerate your tube laser business with a laser power of up to 4 kW. You can also increase the:

- Accuracy

- User-friendliness

- Fully automatic setup of all profiles, including open and elliptical tubes

- Quality and performance in your production

You can also process the following profiles: O ◻ ▯ ⬭ U C L -.

Processing of tubes with lengths from 6000 to a maximum of 12500 mm is possible without any problems, as ones with cross-sections from 10 to 323.9 mm.

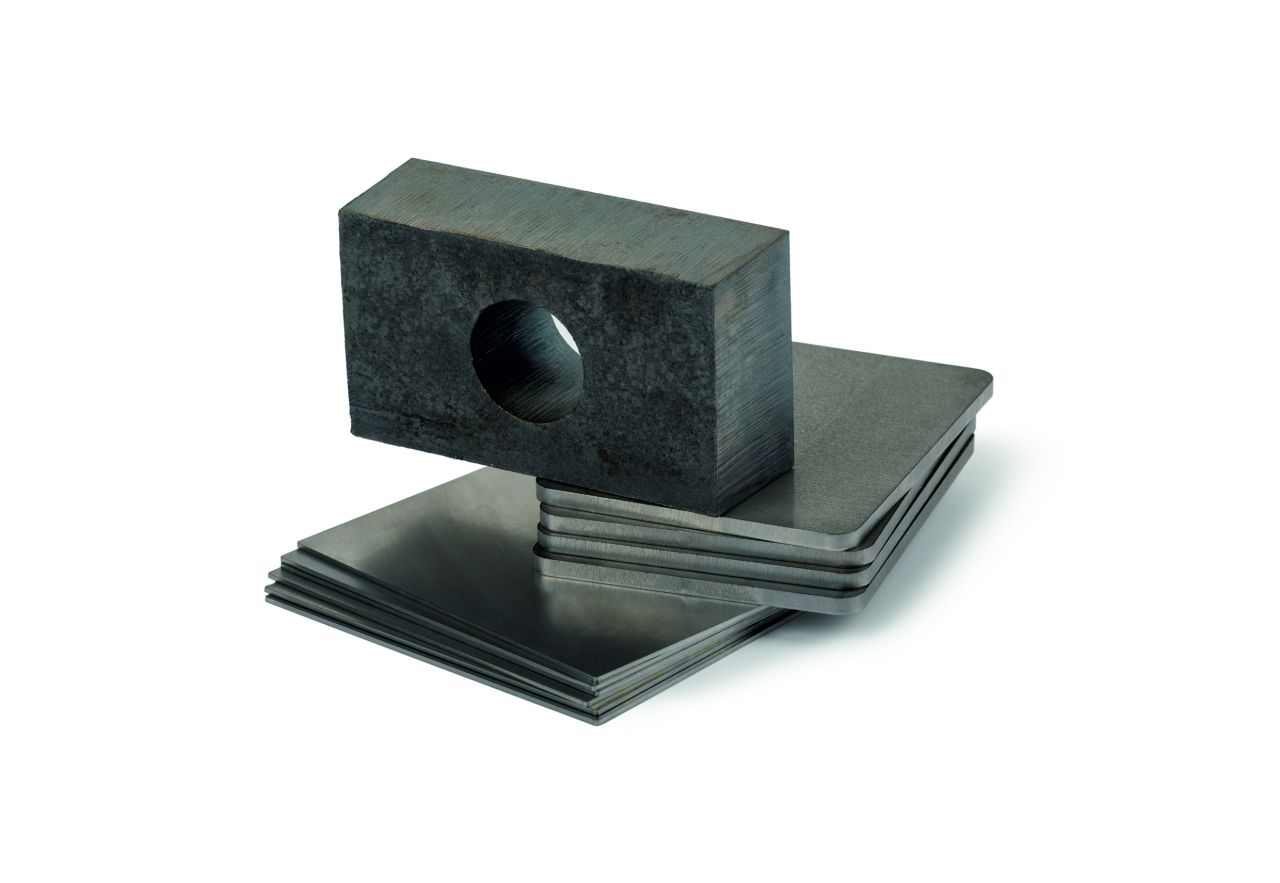

Sheet metal bending with press brakes

Bystronic offers a wide range of press brakes from entry-level to high-performance, for complex bending processes. They can handle sheet thicknesses up to 25 mm.

Our machines are user-friendly. The intuitive software simplifies all process steps and enables convenient bending, even without prior knowledge. In combination with our automation solutions, fully automated production is possible at any time.

There are a variety of steel grades with different properties such as hardness, strength and corrosion resistance. When processingsteel sheet metal, it is important to consider the specific requirements of the respective steel grade to achieve optimal results. With our Smart Features, we ensure that you can bend any type of steel:

- LAMS: The optical angle measuring system is based on lasers and cameras. It uses the sensors to support the bending accuracy of the machines and automatically corrects all deviations that can lead to angular errors.

- Curve Generator: Based on a series of variables, it creates a bending curve. This helps the machine to always approach the same position and bend at the perfect angle. This way, you receive reliable results for every part.

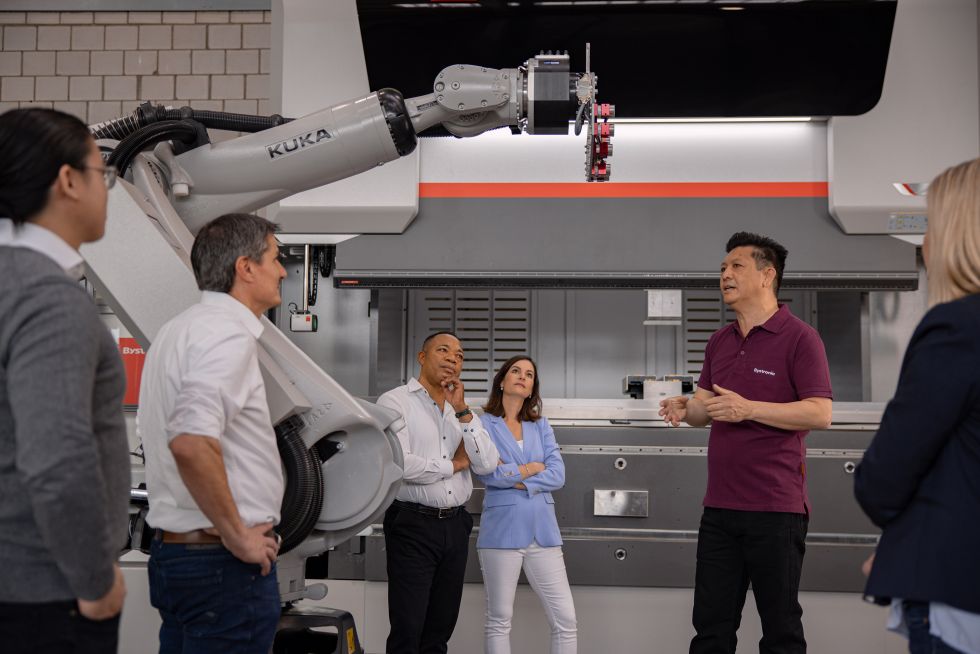

Our steel sheet processing specialists will be happy to support you

Our team is at your side in every phase of your project

- Pre-project phase - Based on your business objectives, we offer you comprehensive advice. We work with you to find the ideal solution.

- Preparation phase - We support you during the entire preparation phase, from the first meeting to the completion of the final layout.

- Realization - We accompany you from delivery to installation and are always at your side.

- Commissioning - Our team ensures that all necessary tests for successful customer acceptance are carried out properly.

- Start of production - We also support you after the start of the project and optimize production with you.

Fit for the future of sheet steel processing with automation

Start optimizing your manufacturing processes on the way to digital production today. With Bystronic, you can gradually achieve your goal of a fully integrated smart factory of the future.

Our automation solutions are characterized by first-class performance and quality.

- Laser cutting machines: Rely on a fully automated sheet loading process with weight control on the elevator and monitoring of tilted parts when unloading the sheets. This is how we guarantee reliable and safe automated production.

- Press brakes: Our bending automation solutions guarantee maximum precision and bending quality. Fully or semi-automated processes for your press brakes save valuable time and money.

Software solutions for simple sheet steel processing

Digitize your company with the BySoft Suite and increase transparency and control along your entire supply chain:

- Link all departments.

- Optimize the efficiency of your machining processes.

- Integrate external systems and machines seamlessly.

- Free your employees from routine tasks so that they can dedicate more time towards more exciting activities.

More sustainability with Bystronic

Bystronic’s sustainability strategy is based on three pillars:

- Optimizing our own sustainability practices

- Promoting sustainability among our customers.

- Helping to shape a more responsible future for our industry.

That is why we are researching and supporting the use of green steel. It has the same properties as conventional steel but is produced without carbon dioxide emissions. This sustainable sheet steel can be processed with all our machines.

Green steel at Naratek: The revolution in sheet steel processing

"The steel industry is estimated to be responsible for 7 to 8 % of global CO2 emissions. By switching reduction process of iron-ore from using coal to using green hydrogen, the CO2 emmissions can be reduced by almost 90 %."

Wilfried Liegard, System Engineer in Robot Automation