News Widal Industri boosts its production power with a ByCut Smart 10 kW

Widal Industri had two laser cutting machines that were starting to get a little old. Maybe it was time to review the machinery, Anders Eriksson- Factory Manager and Niklas Ekelund - Production Coordinator, thought, and visited Bystronic in Stockholm.

We had two older models of laser cutting machine, 1500W and 4000W respectively. It was time to replace them with something new...

Anders Eriksson

The company in Getinge, Halland, is a pure contract manufacturer and its customers are all over the country. Some of them are located nearby.

Here in Getinge, autoclaves are manufactured to sterilize medical equipment. An autoclave heats up steam under pressure, which requires that the equipment is safe to use.

Widal Industri manufactured stainless steel door holders for these, and they are substantial details in 30mm stainless steel. Previously, they made them in the water jet cutting machine, which took 23 hours to make 200 pieces.

We asked a few different manufacturers of fiber laser cutting machines about this and Bystronic replied: Send us a sheet and come up to us in Rosersberg and visit, and you can see for yourself how it works!

Anders Eriksson

An impressive display

The sheet metal was put into the fiber laser and an hour later 200 details were ready! Impressive and almost unreal! Now it was a 15,000W fiber laser, which was a bit too much for their needs, but the technology was the same, so they decided on a 10,000W one, which suited their business better.

90 percent of what we manufacture is stainless steel, and what customers ask for is usually variable in thickness and quantity, what we now think is good about the new laser is the flexibility it offers.

Niklas Ekelund

We have the capacity to handle most things, which has been proven during the six months we have been running with our new investment.

Anders Eriksson

The heart of the company

The normal everyday work is between 2–8 mm stainless steel, although thicknesses of 25–30 occur frequently. They chose a ByCut Smart with Mixgas as additional equipment to be fully flexible in the future depending on their customers' requirements.

Access to spare parts is most important

Three operators have received training on the new investment, and it is running smoothly, but all machines stop from time to time, and an important parameter considered when choosing a supplier was what the service department looks like. If something is not working as it should, it is important to have quick feedback.

There is security in choosing a supplier who is available if you need help with something, or a spare part.

Anders Eriksson

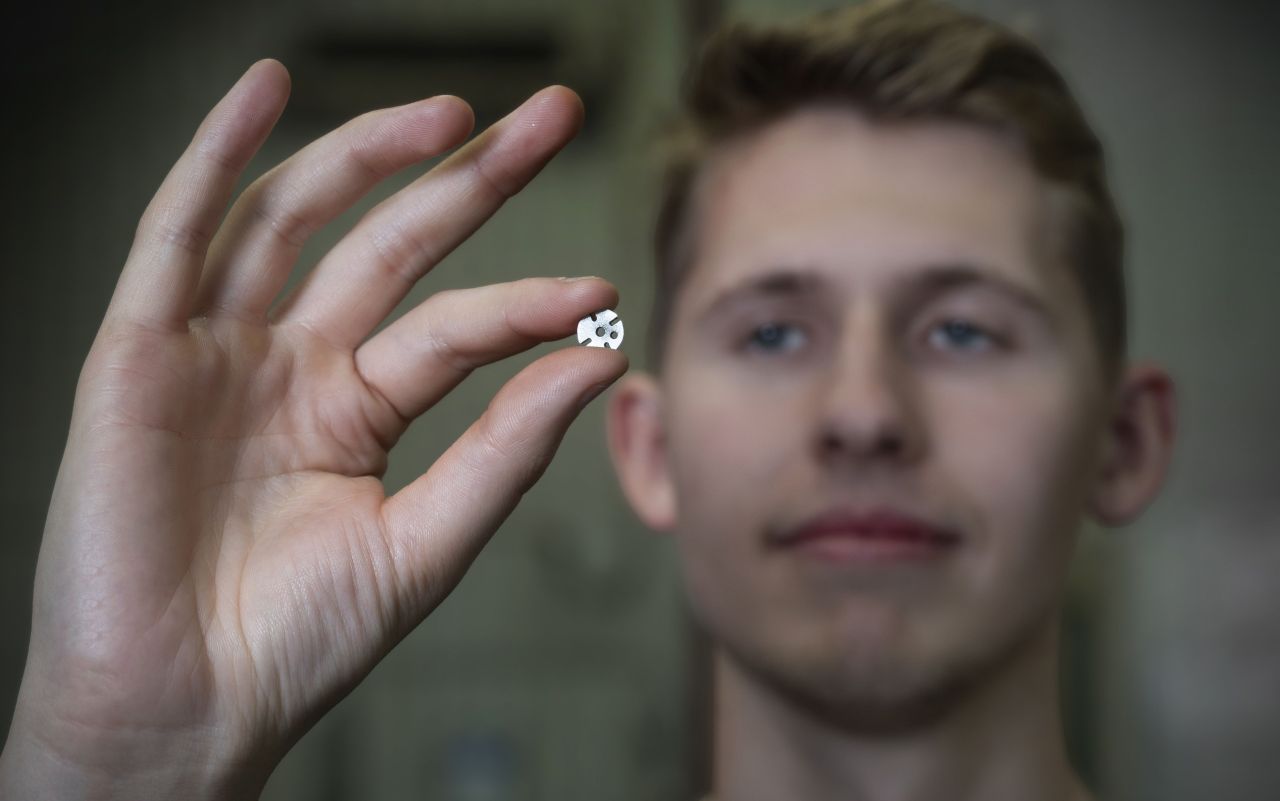

The small in the big

The versatility of the new fiber laser cutting machine is evident in the production of very small parts. The operator and team leader in the sheet metal department, Daniel Bodin, says that they are currently cutting out 1,050 small cable holders from acid-resistant stainless steel. Each detail is so small that you can probably hold 50 of them in your hand!

Flexibility is important if you are a contract manufacturing company.

Daniel Bodin

The company's fine development over the years continues

In 2007, when the company was founded, there were four people employed in production. Today, they have a total of 20 employees, they are investing in the future, and the order intake is growing with more customers...

We bend, mill, turn, weld and provide surface treatment and collaborate with designers and the heart of the facility is our new investment. It feels good.

Anders Eriksson