ByBend Smart Flexible, high-speed press brake machine

High potential Fast, precise, with smart options

The press brake machine, ByBend Smart, offers you the crucial plus in bending technology:

- Speed

- Precision, and

- Numerous smart options

The ByBend Smart offers you new perspectives and guarantees the highest flexibility at attractive terms. The simple operation enables a successful entry into bending technology.

Perfectly precise With active crowning

Active crowning is Bystronic´s innovation that automatically ensures the highest precision and consistent bending accuracy during air bending. Smart sensors guarantee the accuracy of the sheet metal bending machine.

Our press machine uses hydraulic cylinders in the lower beam to provide optimal crowning. The intelligent database allows for optimal adjustment.

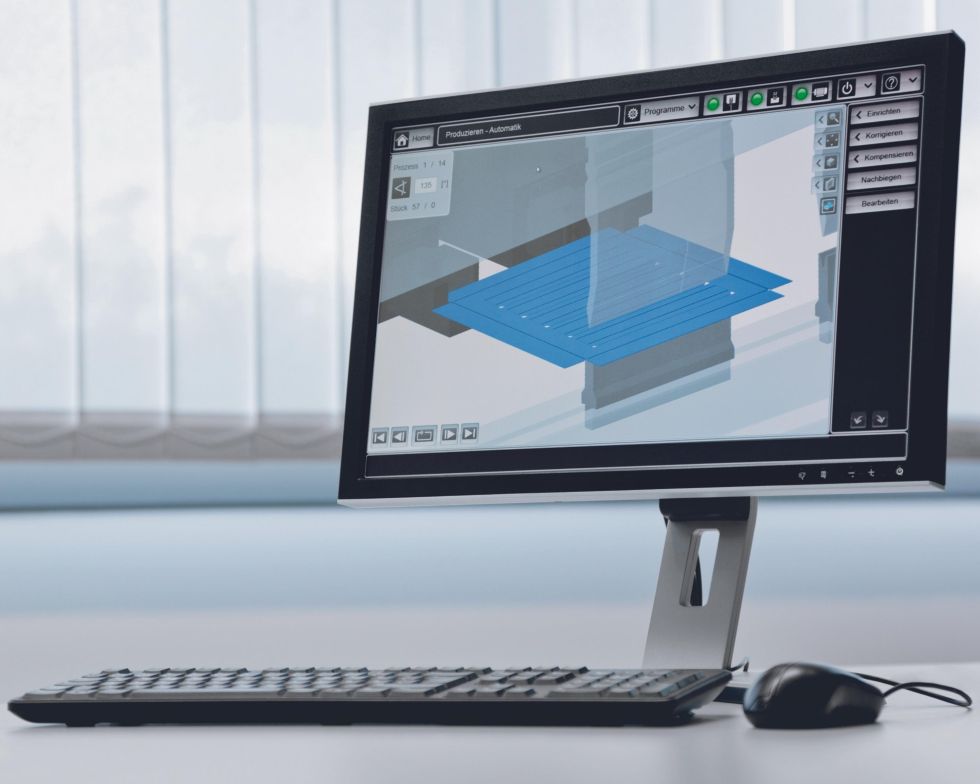

User-friendly Configuration made easy

Load a bending plan, set up the machine, and start bending – with the BySoft Cell Control Bend software, this dream comes true.

The bending process can be controlled conveniently through a touch screen. And best of all: You don't have to think about the ideal bending process and appropriate tools. The press brake machine does this for you.

Energy-efficient Low electric power consumption

The "Energy Saver" helps you to lower your electric power consumption. The machine’s main drive is only active when the machine is actually in operation. Furthermore, both noise and heat are minimized. Your additional plus in sustainability.

High potential Fast, precise, with smart options

The press brake machine, ByBend Smart, offers you the crucial plus in bending technology:

- Speed

- Precision, and

- Numerous smart options

The ByBend Smart offers you new perspectives and guarantees the highest flexibility at attractive terms. The simple operation enables a successful entry into bending technology.

Perfectly precise With active crowning

Active crowning is Bystronic´s innovation that automatically ensures the highest precision and consistent bending accuracy during air bending. Smart sensors guarantee the accuracy of the sheet metal bending machine.

Our press machine uses hydraulic cylinders in the lower beam to provide optimal crowning. The intelligent database allows for optimal adjustment.

User-friendly Configuration made easy

Load a bending plan, set up the machine, and start bending – with the BySoft Cell Control Bend software, this dream comes true.

The bending process can be controlled conveniently through a touch screen. And best of all: You don't have to think about the ideal bending process and appropriate tools. The press brake machine does this for you.

Energy-efficient Low electric power consumption

The "Energy Saver" helps you to lower your electric power consumption. The machine’s main drive is only active when the machine is actually in operation. Furthermore, both noise and heat are minimized. Your additional plus in sustainability.

Do you still have questions about our press brake machine? We are happy to advise you.

Technical specifications All information on the ByBend Smart

| ByBend Smart 100, 160, 225, 300 | |

| Tonnage | 100–300 t |

| Bending length | 3100–4100 mm |

| Daylight | 580 mm |

| Standard stroke | 300 mm |

| Max. high speed | 200 mm/s |

| Max. working speed | 19 mm/s |

| BySoft Cell Control Bend | |

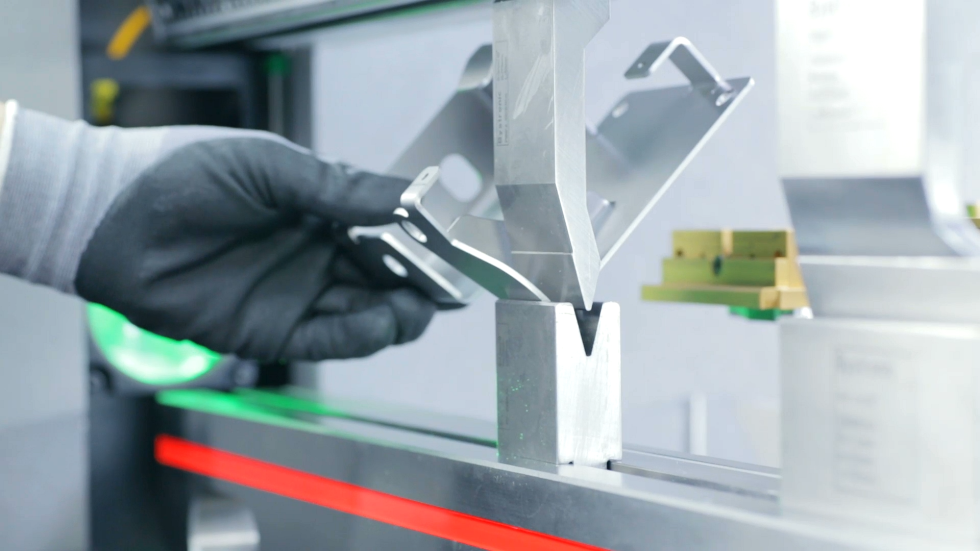

Press brake tooling for press brake machines

Use the full potential of your machine with the original tools. Bystronic bending tools (in a variety of clamping types) can be used with flexibility and versatility to cover all your applications:

- Air bending

- Coining

- 3-point-bending

We are happy to advise you on the design of individual solutions for your products.

Do you need support or have questions about our press brake machine?

Features & options

-

Productivity & Efficiency -

Quality -

Flexibility -

Simplicity -

Future Fit -

Peace of Mind -

Business Success

Speed Options

Higher processing speed – with a selection between the Performance Edition and Dynamic Edition, choose higher speed compared to the Classic Edition.

RFA clamping (Fast clamping System)

With the selection of hydraulic clamping systems, set-up time is reduced. Automatic tool alignment enables optimal and fast work.

Optical Bend Guiding System

Let us guide you – with our Optical Bend Guiding System, we direct you through the entire bending process.

Fast Bend +

For the best comfort and greater efficiency – with Fast Bend + we increase safety during work with our bending machines.

Dynamic crowning

The dynamic crowning system distinguishes itself with increased speed and short cycle times for the Xpert Pro.

LAMS

Outstanding bending accuracy – the optical laser- and camera-based angle measuring system uses sensors to support the bending accuracy of machines.

Optical Bend Guiding System

Let us guide you – with our Optical Bend Guiding System, you receive all the information about the entire bending process.

Automation ready Modular Tool Changer

Parking, moving, adding, removing, and integrated table cleaning enable more efficient work – even during unmanned operation.

Increased stroke and daylight

Extended stroke – for easier bending of narrow or high profiles and for multi-sided parts.

Multi axes back gauge

For more flexibility, the axes for the backgauge vary from 1 to 6 depending on the complexity of the product.

Dynamic Sheet Supports

Simple guidance of thin-gage material during the bending process – synchronized control between the bending aid and bending process.

Detachable Bending line laser

For all applications where the backgauge system is not suitable.

ByVision Bending

The user interface is simple and intuitive in its operation.

Optical Bend Guiding System

With our Optical Bend Guiding System, you receive all the information about the entire bending process.

Fast Bend +

Fast Bend + increases safety while you work with our bending machines.

Multi axes back gauge

Fast Bend + increases safety while you work with our bending machines.

Energy Saver HYBRID & SERVO (Energy & Noise reduction)

Our drive system is equipped with a special control system. This enables capacity according to need, increased speed, reduction of electric power consumption, and noise reduction.

Automation ready

All our machines can be enhanced with automation solutions.

Optical tool detection

For shorter set-up times and increased safety.

Automation ready Modular Tool Changer

Efficient work, even during unmanned operation, with the help of various functions such as parking, moving, adding, removing, and integrated table cleaning.

Dynamic crowning

With the dynamic crowning system for the Xpert Pro press brake, take advantage of increased speed and shorter cycle times.

LAMS

The optical laser- and camera-based angle measuring system uses sensors to support the bending accuracy of machines.

Automation ready

All our machines can be enhanced with automation solutions.

Energy Saver HYBRID & SERVO (Energy & Noise reduction)

Our drive system is equipped with a special control system. This enables capacity according to need, increased speed, reduction of electric power consumption, and noise reduction.

Speed options

Higher processing speed – with a selection between the Performance Edition and Dynamic Edition, choose higher speed compared to the Classic Edition.

Increased stroke and daylight

Extended stroke – for easier bending of narrow or high profiles and for multi-sided parts.

Automation ready

Our machines can be enhanced with automation solutions.

Optical Bend Guiding System

All information at a glance – with our Optical Bend Guiding System, you receive all the information about the entire bending process.

Speed Options

Higher processing speed – with a selection between the Performance Edition and Dynamic Edition, choose higher speed compared to the Classic Edition.

RFA clamping (Fast clamping System)

With the selection of hydraulic clamping systems, set-up time is reduced. Automatic tool alignment enables optimal and fast work.

Optical Bend Guiding System

Let us guide you – with our Optical Bend Guiding System, we direct you through the entire bending process.

Fast Bend +

For the best comfort and greater efficiency – with Fast Bend + we increase safety during work with our bending machines.

Dynamic crowning

The dynamic crowning system distinguishes itself with increased speed and short cycle times for the Xpert Pro.

LAMS

Outstanding bending accuracy – the optical laser- and camera-based angle measuring system uses sensors to support the bending accuracy of machines.

Optical Bend Guiding System

Let us guide you – with our Optical Bend Guiding System, you receive all the information about the entire bending process.

Automation ready Modular Tool Changer

Parking, moving, adding, removing, and integrated table cleaning enable more efficient work – even during unmanned operation.

Increased stroke and daylight

Extended stroke – for easier bending of narrow or high profiles and for multi-sided parts.

Multi axes back gauge

For more flexibility, the axes for the backgauge vary from 1 to 6 depending on the complexity of the product.

Dynamic Sheet Supports

Simple guidance of thin-gage material during the bending process – synchronized control between the bending aid and bending process.

Detachable Bending line laser

For all applications where the backgauge system is not suitable.

ByVision Bending

The user interface is simple and intuitive in its operation.

Optical Bend Guiding System

With our Optical Bend Guiding System, you receive all the information about the entire bending process.

Fast Bend +

Fast Bend + increases safety while you work with our bending machines.

Multi axes back gauge

Fast Bend + increases safety while you work with our bending machines.

Energy Saver HYBRID & SERVO (Energy & Noise reduction)

Our drive system is equipped with a special control system. This enables capacity according to need, increased speed, reduction of electric power consumption, and noise reduction.

Automation ready

All our machines can be enhanced with automation solutions.

Optical tool detection

For shorter set-up times and increased safety.

Automation ready Modular Tool Changer

Efficient work, even during unmanned operation, with the help of various functions such as parking, moving, adding, removing, and integrated table cleaning.

Dynamic crowning

With the dynamic crowning system for the Xpert Pro press brake, take advantage of increased speed and shorter cycle times.

LAMS

The optical laser- and camera-based angle measuring system uses sensors to support the bending accuracy of machines.

Automation ready

All our machines can be enhanced with automation solutions.

Energy Saver HYBRID & SERVO (Energy & Noise reduction)

Our drive system is equipped with a special control system. This enables capacity according to need, increased speed, reduction of electric power consumption, and noise reduction.

Speed options

Higher processing speed – with a selection between the Performance Edition and Dynamic Edition, choose higher speed compared to the Classic Edition.

Increased stroke and daylight

Extended stroke – for easier bending of narrow or high profiles and for multi-sided parts.

Automation ready

Our machines can be enhanced with automation solutions.

Optical Bend Guiding System

All information at a glance – with our Optical Bend Guiding System, you receive all the information about the entire bending process.

Highlights Sheet metal bending machines: Increase output while saving energy

Bystronic Service Tailor-made for your needs and smooth production

ByCare packages

Our trained service experts ensure efficient production processes and safety for your employees. Depending on the requirements, we offer packages with basic to all-around services.

360° Customer Advisor

We analyze your production and determine your strengths and weaknesses. Based on this information, you can optimize processes and decrease downtime.

Our services

We maintain and repair your Bystronic systems. Optionally, you can obtain upgrades to retrofit your system or accessories to fine-tune your solution. Upon request, we can also perform a general overhaul.

Our service experts are always there for you – quickly and in person

Software for your press brake machine BySoft Cell Control Bend: Bending conveniently with the right software

The ergonomic design and individually configurable work environment provide a high degree of bending comfort. The intuitive software complements your press brake machines and makes bending convenient. With BySoft Cell Control Bend, you easily control all process steps.

BySoft CAM Bending allows for intuitive offline programming, which creates bending programs in a matter of seconds. With BySoft InSight, you are able to check your press brake production in real time.