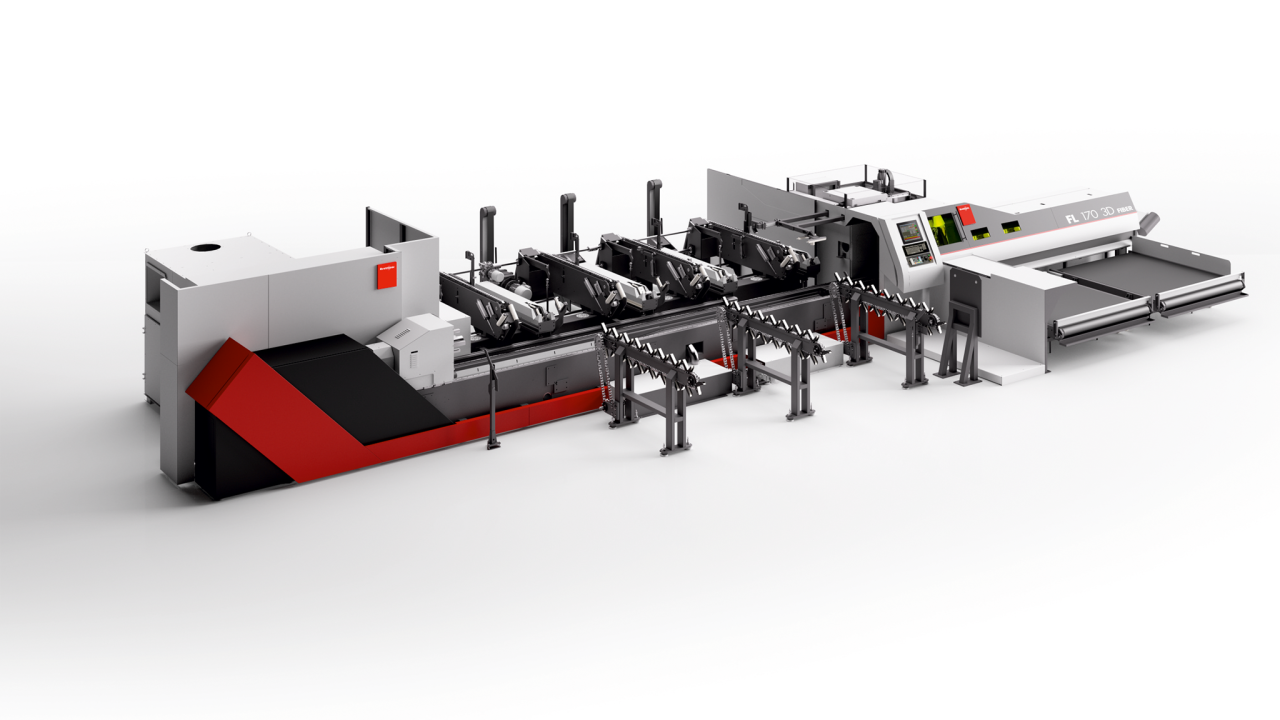

FL 170 The 3D tube laser cutting machine opens up unlimited application possibilities

Laser processing using the FL 170 Fast cutting processes boost your profits

The FL 170 fiber laser combines the benefits of a fiber laser with the versatility of 3D cutting. The cutting spectrum can be extended to open sections, such as beams, angles and channels. The FL 170 3D tube laser cutting machine excels thanks to its low power consumption and low maintenance requirements.

Customized laser cutting 2D and 3D laser cutting technology for high-precision parts

A wide range of tubes with circular, square, and rectangular geometries as well as open sections are precisely machined using 2D and 3D laser cutting technology. 3D tube laser cutting at angles of up to 45 degrees, as preparation for the welding process, is also possible. Thanks to tube laser cutting, there is no need for time-consuming milling, drilling, or sawing.

High level of safety For both small and large production runs

The automatic loading system facilitates the loading of material and enhances operator safety. This offers you the flexibility you need to fulfill your customers’ requirements.

Maximum ease of operation Simple and fast loading and unloading

Excellent accessibility to all working areas and the loading area ensure you have the flexibility you need to handle both small and large batches. Perfectly integrate the FL 170 into your material flow, by choosing whether you want to load or unload on the left or the right side of the operator stand.

Laser sources for the FL 170 For 3D tube laser cutting

Our laser sources cut a variety of materials with minimal maintenance requirements and low power consumption. Consistently high cutting quality for steel, stainless steel, and aluminum. The 3D tube and profile laser cutting machine excels at high-speed cutting.

Laser processing using the FL 170 Fast cutting processes boost your profits

The FL 170 fiber laser combines the benefits of a fiber laser with the versatility of 3D cutting. The cutting spectrum can be extended to open sections, such as beams, angles and channels. The FL 170 3D tube laser cutting machine excels thanks to its low power consumption and low maintenance requirements.

Customized laser cutting 2D and 3D laser cutting technology for high-precision parts

A wide range of tubes with circular, square, and rectangular geometries as well as open sections are precisely machined using 2D and 3D laser cutting technology. 3D tube laser cutting at angles of up to 45 degrees, as preparation for the welding process, is also possible. Thanks to tube laser cutting, there is no need for time-consuming milling, drilling, or sawing.

High level of safety For both small and large production runs

The automatic loading system facilitates the loading of material and enhances operator safety. This offers you the flexibility you need to fulfill your customers’ requirements.

Maximum ease of operation Simple and fast loading and unloading

Excellent accessibility to all working areas and the loading area ensure you have the flexibility you need to handle both small and large batches. Perfectly integrate the FL 170 into your material flow, by choosing whether you want to load or unload on the left or the right side of the operator stand.

Laser sources for the FL 170 For 3D tube laser cutting

Our laser sources cut a variety of materials with minimal maintenance requirements and low power consumption. Consistently high cutting quality for steel, stainless steel, and aluminum. The 3D tube and profile laser cutting machine excels at high-speed cutting.

Expand your range of applications with the FL 170 3D tube laser cutting machine.

Video FL 170

Bystronic’s products for the 3D laser cutting of tubes and profiles are used in a wide range of industries. From the automotive industry to furniture design and right through to architecture, the laser-assisted processing of tubes offers unlimited possibilities.

Highlights from the video

Concentrated technology

The FL 170 3D tube laser cutting machine combines the unique benefits of fiber laser technology with the versatility of 3D cutting.

Any geometry

3D tube laser cutting – no matter whether you process round, square, or rectangular geometries – becomes a breeze. Even a variety of profiles with open cross-sections (for example, H-beams, angles and channels) can be processed effortlessly thanks to the 3D cutting head.

Bevels and angles

Thanks to 3D technology, you can even perform cuts at angles of up to 45 degrees. Thanks to this wide range of processing options, you eliminate the need for time-consuming milling, drilling, punching, or sawing, and prepare the material for the welding process.

Full range of applications

High-precision cutting of tubes made of steel, stainless steel, and aluminum with diameters from 12 to 168 millimeters and workpiece length up to 6.1 m

Our experts will help you choose the ideal fiber laser for your applications.

Bystronic Service Tailor-made for your needs and smooth production

ByCare packages

Our trained service experts ensure efficient production processes and safety for your employees. Depending on the requirements, we offer packages with basic to all-around services.

360° Customer Advisor

We analyze your production and determine your strengths and weaknesses. Based on this information, you can optimize processes and decrease downtime.

Our services

We maintain and repair your Bystronic systems. Optionally, you can obtain upgrades to retrofit your system or accessories to fine-tune your solution. Upon request, we can also perform a general overhaul.

Our service experts are always there for you – quickly and in person

Software TTMotion: The convenient solution for optimized configurations

The TTMotion smart software solution helps you to specify the correct parameters. The solution ensures that your FL 170 3D tube laser cutting machine achieves outstanding results.