Precise aluminum processing with Bystronic Machines, software and automation of the future

High-precision aluminum machining For quality products

Aluminum is a resistant light metal with a low density. It is used in the automotive and aviation industries, for example.

Our laser cutting machines, tube lasers, press brakes, automation and software solutions offer the necessary precision and the right parameters for high-quality aluminum processing without:

- Scratches

- Discolorations

- Irregularities

- Corrosion

Do you have questions about aluminum processing with Bystronic? We will be happy to help you.

Aluminum processing with laser cutting machines

Aluminum has a high thermal conductivity, which means that heat spreads quickly through the material during the machining process. This has to be considered when choosing parameters like cutting speed.

Laser cutting machines by Bystronic perfectly match cutting parameters to aluminum for precise and reliable processing. We also cut with oxygen and compressed air, as it is more efficient for processing aluminum.

Aluminum processing with tube lasers

Tube lasers from Bystronic offer laser power of up to 4 kW. They increase the accuracy of aluminum processing, user-friendliness, the fully automatic setup of all profiles and the quality of your production.

You can edit the following:

- Profiles: O ◻ ▯ ⬭ U C L -

- Pipe lengths: 6000 to a maximum of 12500 mm

- Cross-sections: 10 to 323.9 mm

Aluminum processing with press brakes

Aluminium has a different mechanical behavior when compared to other materials such as steel or stainless steel. Aluminum is softer compared to other materials, so specific bending parameters are important for an optimal result. Choosing the right tools is also crucial for efficient aluminum processing.

Press brakes from Bystronic are equipped with user-friendly software. It simplifies all process steps and offers convenient bending, even without prior knowledge.

With our Smart Features, we ensure that you can bend aluminum accurately:

- LAMS: The optical angle measurement system works with lasers and cameras. The built-in sensors support the bending accuracy.

- Curve Generator: This software creates a bending curve that helps the machine to always approach the same position and bend at the ideal angle.

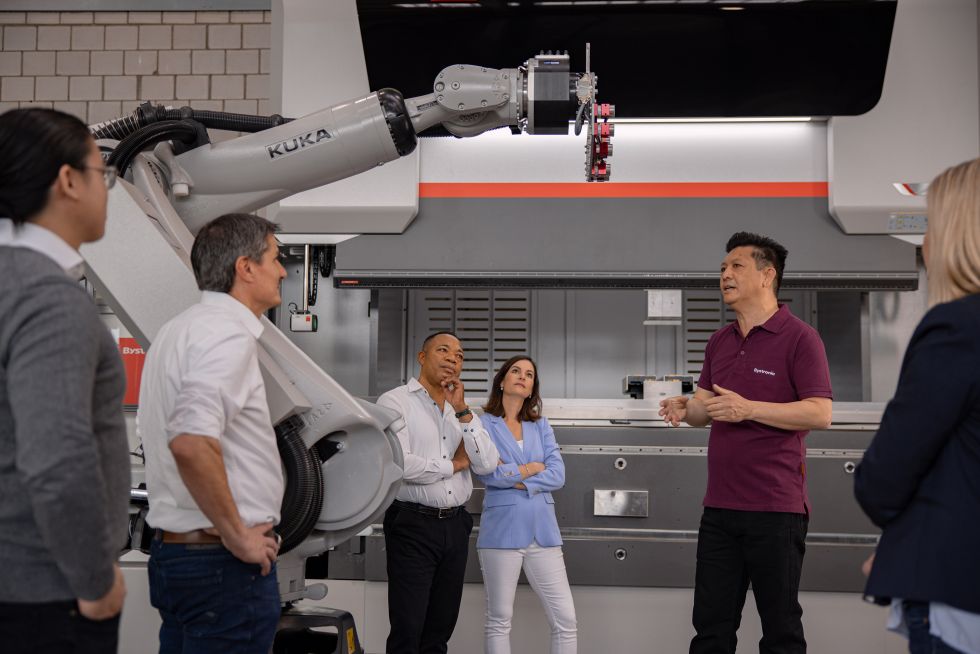

Our specialists for aluminum processing will be happy to support you

Our team is at your side in every phase of your project:

- Pre-project phase - Depending on your business objectives, we offer individual, comprehensive advice. Together we will find the ideal solution for your application.

- Preparation phase - We help you during the preparation phase from the first meeting to the final layout.

- Realization - We are always at your side from delivery to installation.

- Commissioning - Our team ensures that all necessary tests are carried out for successful customer acceptance.

- Start of production - We are here for you after the start of the project and optimize production with you.

Fit for the aluminum processing of the future with automation

Start optimizing your manufacturing processes today on the way to digital production. With Bystronic, you will gradually achieve your goal of a fully integrated smart factory of the future:

- Laser cutting machines: You can rely on a fully automated sheet loading process with weight control on the elevator and monitoring of the tilted parts when unloading the sheets. This ensures reliable automated production.

- Press brakes: Our bending automation solutions guarantee precision and bending quality. Our fully or semi-automated processes for your press brakes save you time and money.

Software solutions for simple aluminum processing

Digitize your company with the BySoft Suite. Increase transparency and control along the entire supply chain:

- Establish a connection between all departments.

- Increase the efficiency of your tube laser processes.

- Integrate external systems and machines seamlessly.

- Relieve your employees of repetitive tasks so that they can concentrate on more interesting activities.