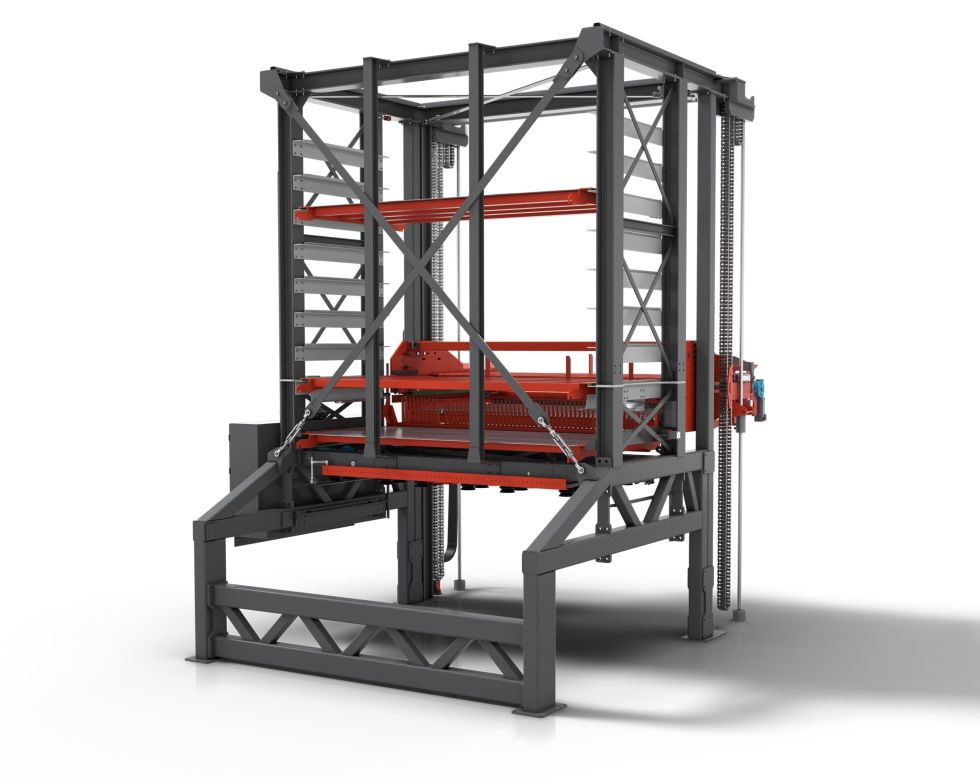

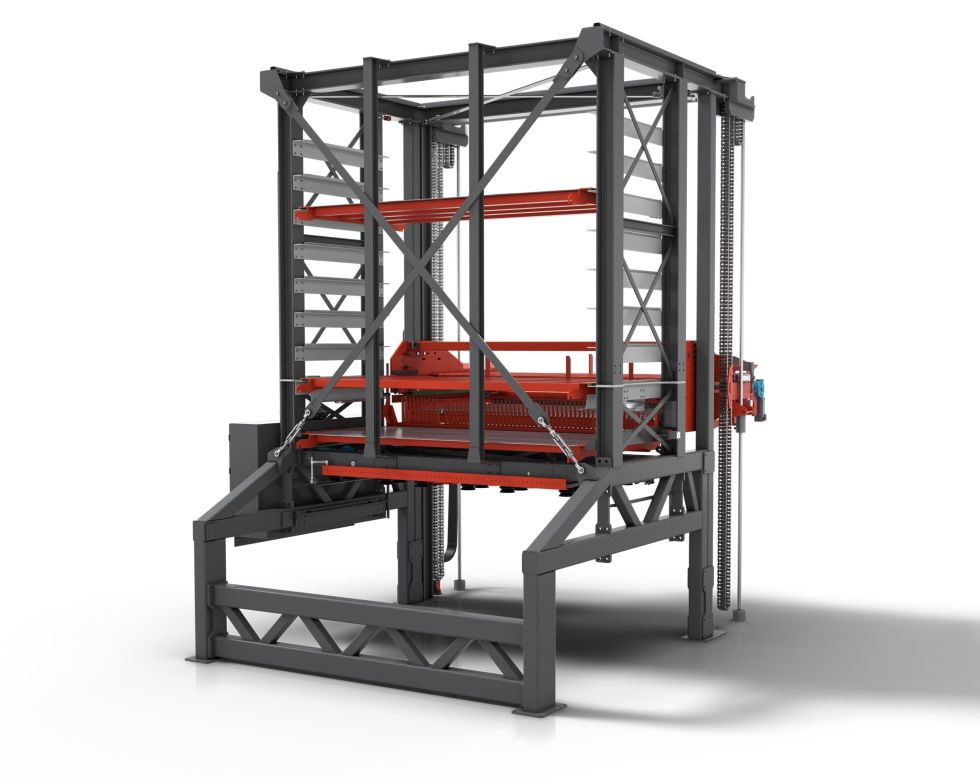

ByTower Compact Automated loading and unloading for laser automation from Bystronic

Loading and unloading Laser automation with a storage tower

The system for loading & unloading the ByTower Compact is combined with a storage tower. With this smart design the ByTower Compact increases the productivity of your Bystronic laser cutting machine without requiring much space.

The system has been designed to take up as little floor space as possible. The fully automated cassette changing enables lightly manned or unmanned production for companies of any size.

Compact & automated Higher productivity thanks to automation

Bystronic's compact system for laser cutting enables fully automated loading and unloading of cassettes.

Our automation solutions have many advantages:

- Your material flow is optimized.

- Your machine utilization is improved.

- The work and process safety of your production is increased.

Optimal space utilization Compact system for lightly manned manufacturing

The system has been designed to take up as little floor space as possible. In order to make optimum use of the available space, the height of the storage tower can be customized to meet your precise requirements. This makes the ByTower Compact the all-in-one solution for lightly manned or unmanned production.

Fast material loading Reduced idle time, increased productivity

The loading and unloading of the laser’s shuttle table is performed automatically. This results in:

- A higher utilization rate of the overall system.

- Elimination or a significant reduction in idle times.

- Higher productivity.

Loading and unloading Laser automation with a storage tower

The system for loading & unloading the ByTower Compact is combined with a storage tower. With this smart design the ByTower Compact increases the productivity of your Bystronic laser cutting machine without requiring much space.

The system has been designed to take up as little floor space as possible. The fully automated cassette changing enables lightly manned or unmanned production for companies of any size.

Compact & automated Higher productivity thanks to automation

Bystronic's compact system for laser cutting enables fully automated loading and unloading of cassettes.

Our automation solutions have many advantages:

- Your material flow is optimized.

- Your machine utilization is improved.

- The work and process safety of your production is increased.

Optimal space utilization Compact system for lightly manned manufacturing

The system has been designed to take up as little floor space as possible. In order to make optimum use of the available space, the height of the storage tower can be customized to meet your precise requirements. This makes the ByTower Compact the all-in-one solution for lightly manned or unmanned production.

Fast material loading Reduced idle time, increased productivity

The loading and unloading of the laser’s shuttle table is performed automatically. This results in:

- A higher utilization rate of the overall system.

- Elimination or a significant reduction in idle times.

- Higher productivity.

Boost your productivity with the ByTower Compact from Bystronic. We will be happy to answer any questions you may have.

Technical specifications All information on the ByTower Compact

| ByTower Compact 3015 + ByTower Compact 3015 P | |

| Nominal sheet size | 3000 x 1500 mm |

| Maximum sheet size | 3025 x 1520 mm |

| Sheet metal thickness | 25 mm |

| Maximum sheet weight | 900 kg |

| Load/unload approx cycle time without Fast Cycle (+N) option | 180 s |

| Load/unload approx cycle time with Fast Cycle (+N) option | 70 s |

Videos ByTower Compact

The system takes up minimal floor space. The automated loading and unloading of cassettes enables unsupervised production.

Highlights from the video

Increased production

The ByTower Compact automates the loading and unloading workflow of your laser cutting system. This translates into significantly more parts in less time.

Autonomous production

Automation enables unsupervised manufacturing. This frees up your staff for tasks.

Variable heights

The tower height is customizable to meet any requirement. In this way, you make optimum use of the available space.

Two configurations

You can choose between two different configurations to handle sheet metal stacks either with or without wooden pallets.

We are happy to answer all your questions about the automated loading and unloading of your laser cutting system.

Bystronic Service Tailor-made for your needs and smooth production

ByCare packages

Our trained service experts ensure efficient production processes and safety for your employees. Depending on the requirements, we offer packages with basic to all-around services.

360° Customer Advisor

We analyze your production and determine your strengths and weaknesses. Based on this information, you can optimize processes and decrease downtime.

Our services

We maintain and repair your Bystronic systems. Optionally, you can obtain upgrades to retrofit your system or accessories to fine-tune your solution. Upon request, we can also perform a general overhaul.

Our service experts are always there for you – quickly and in person

Software for more efficient processes BySoft Suite for networked production

The future of sheet processing lies in intelligent production. In order to master these challenges, Bystronic has developed a trend-setting software. It enables your company to optimally control your production. All areas in the company are digitalized and linked by the software. It ensures seamless communication and efficient control of production.

Let Bystronic guide you into the digital future of sheet metal processing.