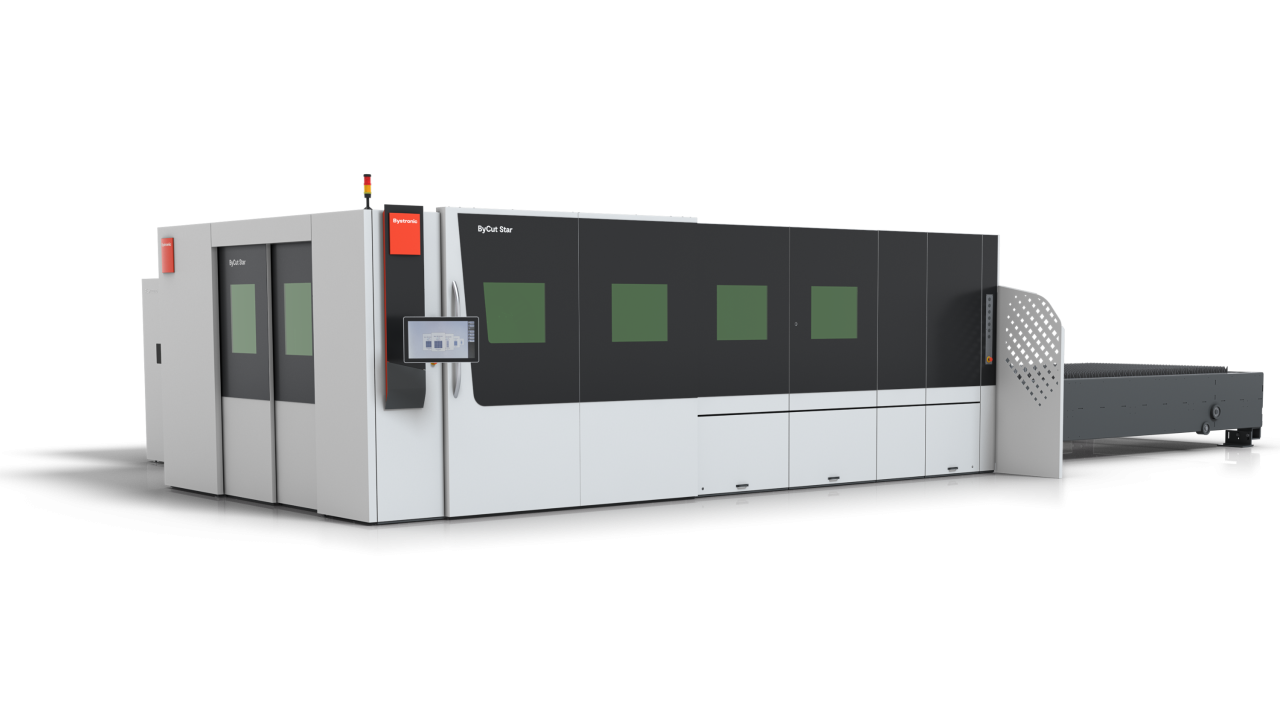

ByCut Star Mere effektiv og gennemtænkt laserskærer

Hurtig og intelligent Den nye laserskærer ByCut Star

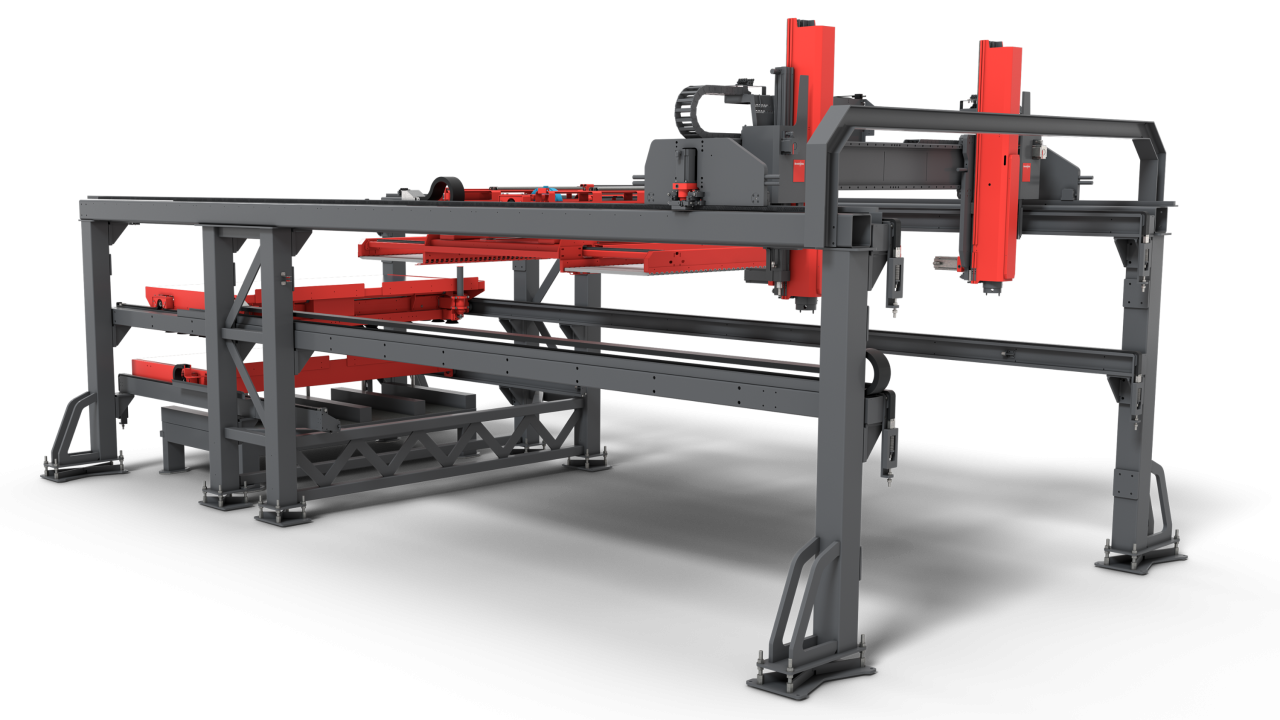

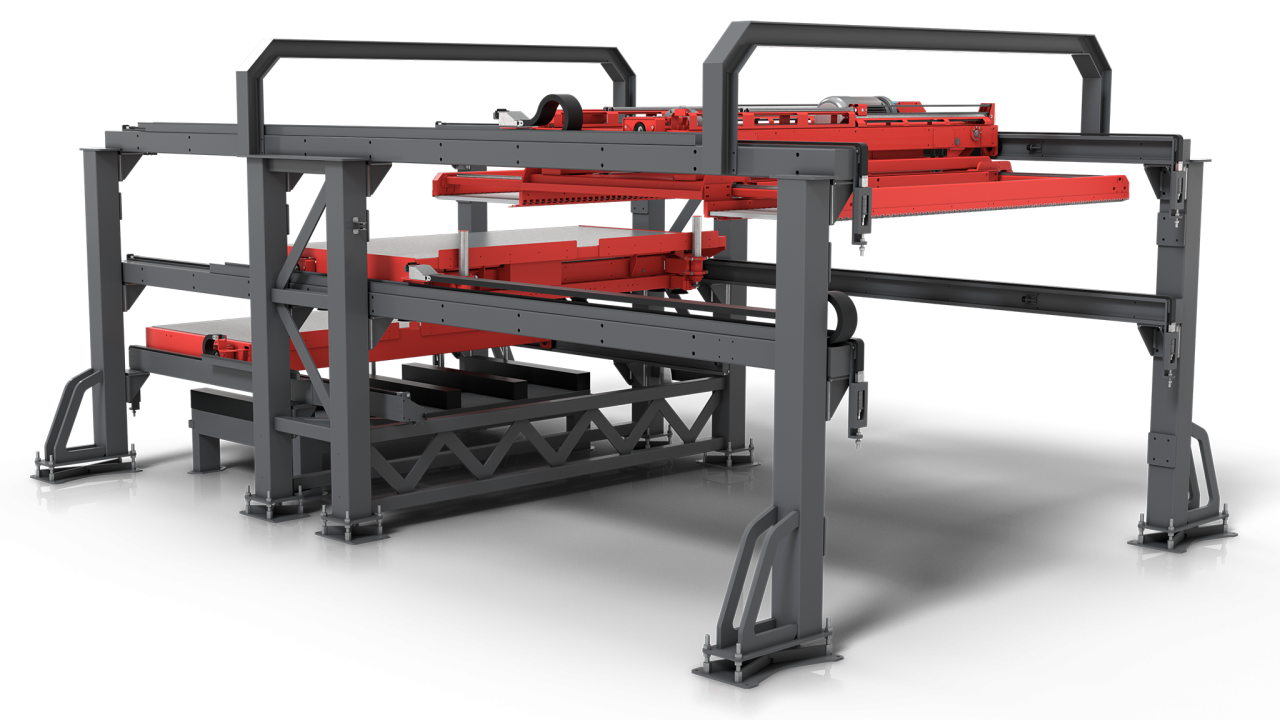

ByCut Star 3015: Den kompakte maskine med stor ydelse. Med den kan du skære plader op til 3 x 1,5 meter hurtigt og præcist.

ByCut Star 4020: Endnu flere plader, endnu højere produktivitet. Da du kan skære større plader med samme høje laserydelse, øger du outputtet.

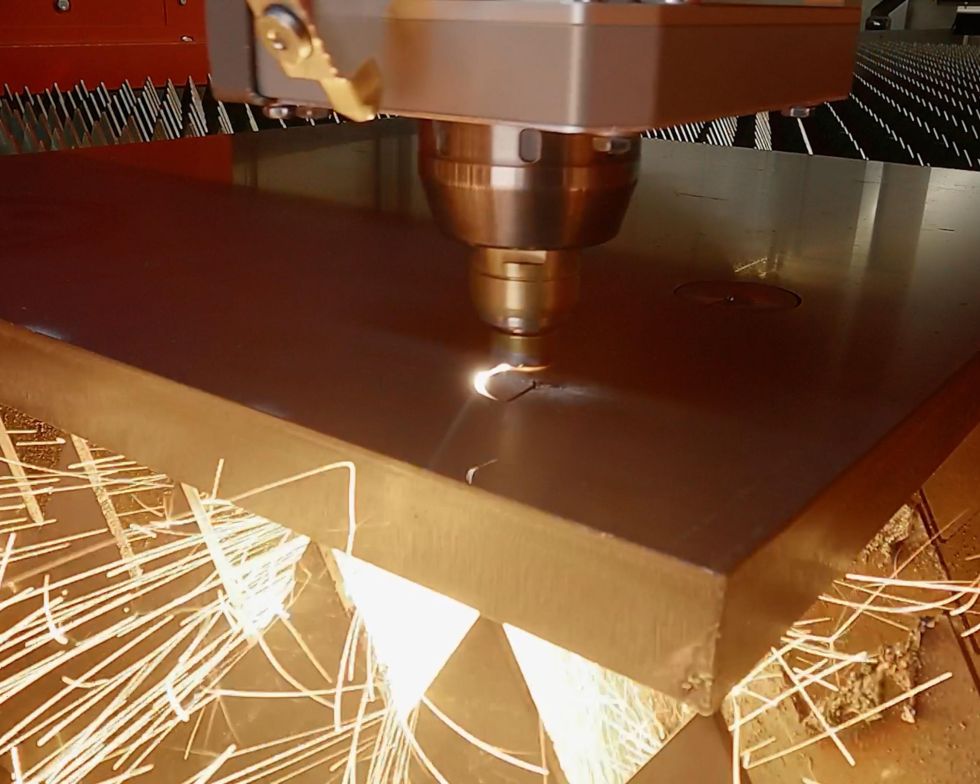

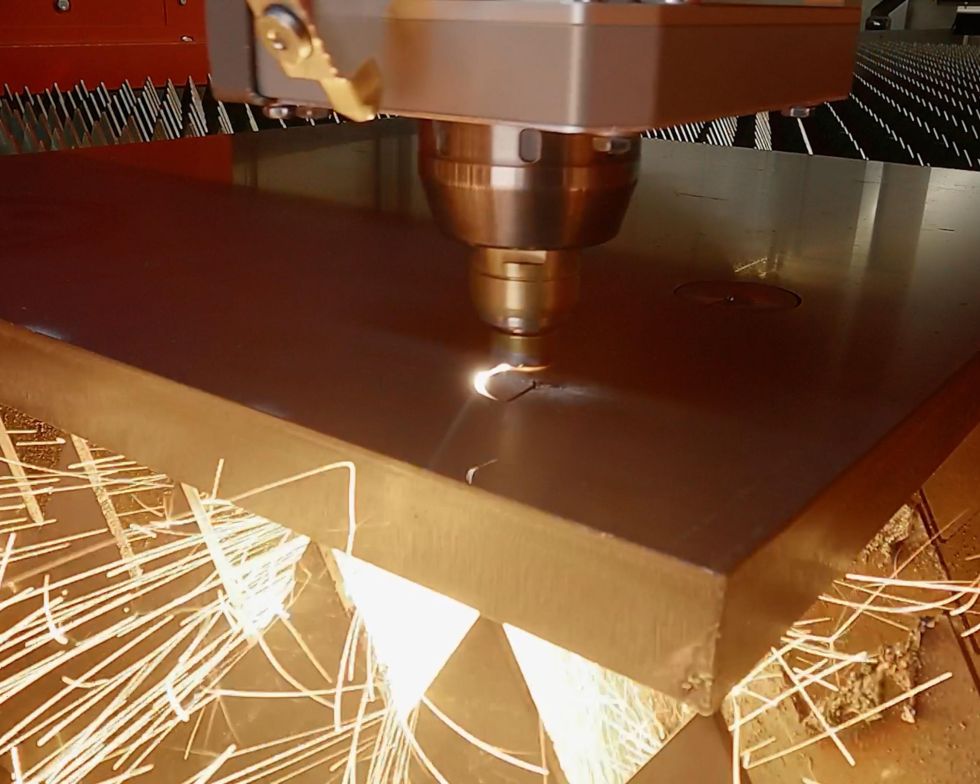

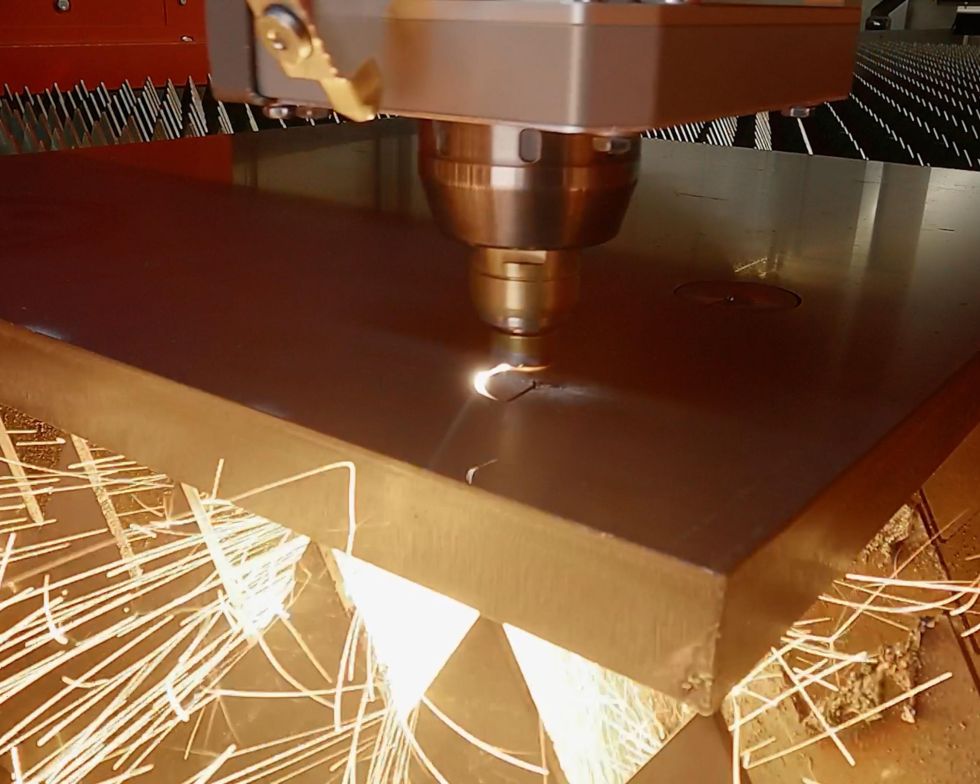

En høj skærehastighed, en intelligent skæreproces og et nyt design – det er den nye ByCut Star. Fiberlaserskæreren giver endnu højere kvalitet og sikrer præcis og sikker bearbejdning med en optimeret skæreproces:

- Stål

- Aluminium

- Rustfrit stål

- Messing

- Kobber

30 kW-laserydelse Skift et gear op

Vores laserskærer giver en laserydelse på op til 30 kW. Dermed kan du skære plader i blødt stål på mellem 6 mm og 15 mm dobbelt så hurtigt som 15 kW og MixGas. Fra 20 mm stiger hastigheden til mere end det dobbelte. Hurtigere gennemskæring ved pladetykkelse over 15 mm sikrer desuden hurtigere arbejde.

Smarte funktioner Power uden intelligens er ikke noget værd

Tilfør din skæreproces yderligere drive – med smarte funktioner som:

- «Intelligent Cutting Process (ICP)»

- «Parameter Wizard»

Sådan optimerer du hele skæreprocessen. Med tilvalget «Parameter Wizard» finder du hurtigt de perfekte parametre til stål fra 4 til 15 mm med N2 og MixGas. På den måde sparer du kostbar tid og sætte endnu mere fart i produktionen.

Lettere bliver det ikke Med vores laserskærer kommer arbejdet til at gå som en leg

Via en berøringsskærm på 21,5" kan Bystronic-softwaren BySoft Cell Control Cut betjenes lige så let som en smartphone. Selv brugere med begrænset erfaring kan anvende softwaren.

Hurtig og intelligent Den nye laserskærer ByCut Star

ByCut Star 3015: Den kompakte maskine med stor ydelse. Med den kan du skære plader op til 3 x 1,5 meter hurtigt og præcist.

ByCut Star 4020: Endnu flere plader, endnu højere produktivitet. Da du kan skære større plader med samme høje laserydelse, øger du outputtet.

En høj skærehastighed, en intelligent skæreproces og et nyt design – det er den nye ByCut Star. Fiberlaserskæreren giver endnu højere kvalitet og sikrer præcis og sikker bearbejdning med en optimeret skæreproces:

- Stål

- Aluminium

- Rustfrit stål

- Messing

- Kobber

30 kW-laserydelse Skift et gear op

Vores laserskærer giver en laserydelse på op til 30 kW. Dermed kan du skære plader i blødt stål på mellem 6 mm og 15 mm dobbelt så hurtigt som 15 kW og MixGas. Fra 20 mm stiger hastigheden til mere end det dobbelte. Hurtigere gennemskæring ved pladetykkelse over 15 mm sikrer desuden hurtigere arbejde.

Smarte funktioner Power uden intelligens er ikke noget værd

Tilfør din skæreproces yderligere drive – med smarte funktioner som:

- «Intelligent Cutting Process (ICP)»

- «Parameter Wizard»

Sådan optimerer du hele skæreprocessen. Med tilvalget «Parameter Wizard» finder du hurtigt de perfekte parametre til stål fra 4 til 15 mm med N2 og MixGas. På den måde sparer du kostbar tid og sætte endnu mere fart i produktionen.

Lettere bliver det ikke Med vores laserskærer kommer arbejdet til at gå som en leg

Via en berøringsskærm på 21,5" kan Bystronic-softwaren BySoft Cell Control Cut betjenes lige så let som en smartphone. Selv brugere med begrænset erfaring kan anvende softwaren.

Sæt skub i produktionen med vores laserskærer ByCut Star.

Tekniske data Alle oplysninger og data vedrørende ByCut Star

| ByCut Star | 3015 | 4020 |

| Plåtdimensioner | 3000 x 1500 mm | 4000 x 2000 mm |

| Maximal positioneringshastighet, simultan | 170 m/min | 170 m/min |

| Maximal arbetsstyckevikt | 1550 kg | 1900 kg |

| Manövrering med BySoft Cell Control Cut och manuell styrenhet | | |

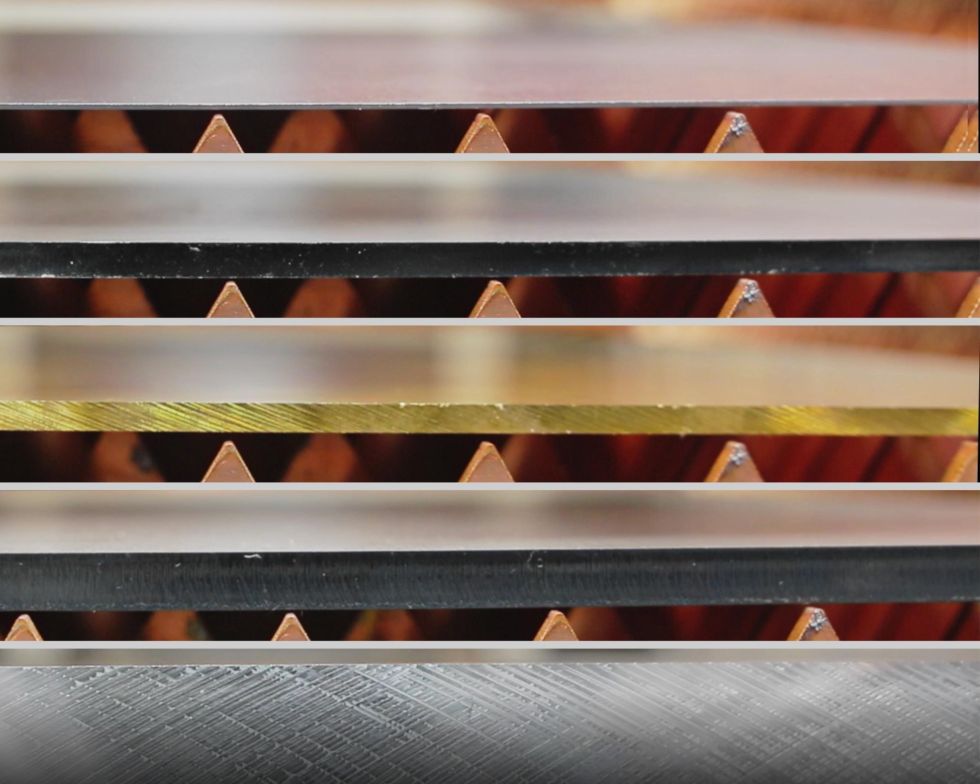

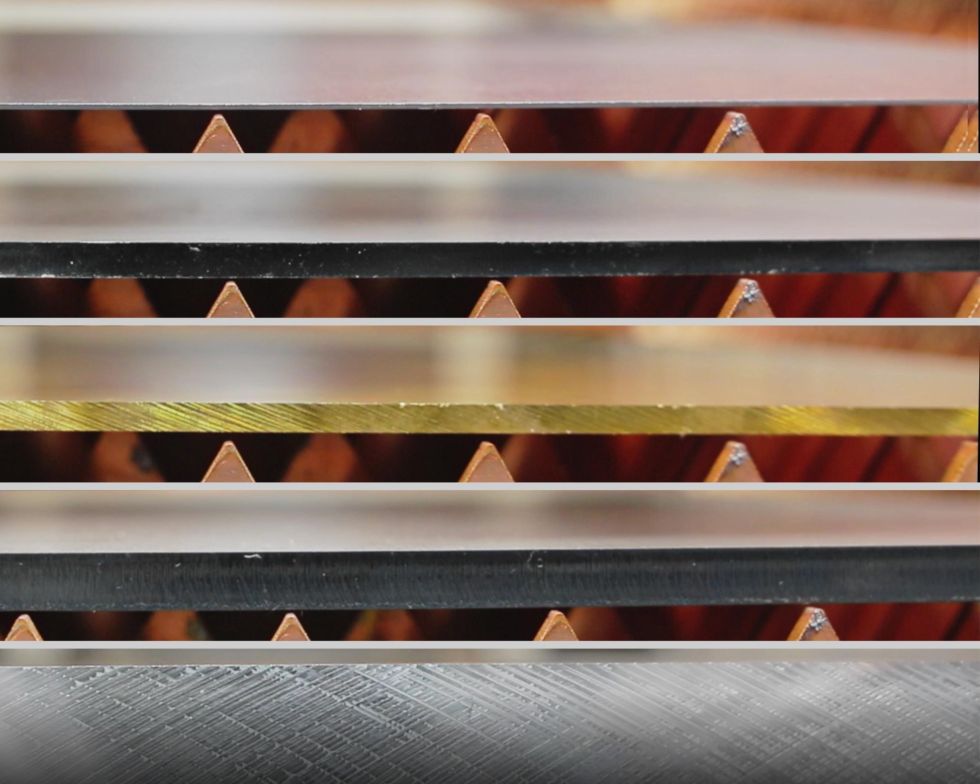

Bystronic MixGas Laserskæring med nitrogen og oxygen

Laserskæring med Bystronics laserblandingsgas giver rene snit og minimale grater. Vores unikke blanding af nitrogen og oxygen giver en klar fordel i forhold til fusions- og flammeskæring.

Forvandl din produktionsproces, og nyd bedre skærekvalitet ved højere hastigheder. Fremstil dele i topkvalitet, selv af materialer af lav kvalitet. Bystronic MixGas kan nemt tilføjes til dit eksisterende lasersystem.

Funktioner og tilvalg

-

Productivity & Efficiency -

Quality -

Flexibility -

Simplicity -

Future Fit -

Peace of Mind -

Business Success

High Laser Power

A high laser power increases productivity, improves cutting quality, and allows even thicker sheet metal to be machined economically. An essential component for high-power cutting is the right cutting head.

Intelligent Cutting Process

Increase your productivity: The cutting process is stable thanks to comprehensive process monitoring.

Cutting Head / Protective Glass

Precision & speed – using the Bystronic cutting head, you can machine thin and thick materials with the highest quality. The integrated changing system also allows fast maintenance of the protective glass.

MixGas

With a mixture of nitrogen and oxygen, we combine the benefits of each cutting method. Excellent cutting quality, as with pure oxygen, combined with the high cutting speeds of pure nitrogen.

Parameter Wizard

Use the Parameter Wizard to determine the optimum cutting parameters in a matter of minutes and achieve a lower cost per unit.

NCT & KerfScan

The Nozzle Control Tool (NCT) makes it possible to center nozzles quickly and reliably, as well as monitor the nozzle state. KerfScan checks the cutting process when flame cutting steel, detects problems, and solves them. This ensures a stable process without operator interaction.

BeamShaper

The manual or automatic BeamShaper in the cutting head helps when the material quality is poor. Improves cutting quality and increases process stability when cutting medium and thick mild steel.

ByPos Fiber

ByPos Fiber automatically sets the focus position according to the material and its thickness. The focus position is optimally matched to the process.

Spot Control

Depending on the sheet thickness and the material, Spot Control automatically adapts the focal point to it.

Detection Eye

More precision: Using a camera system on the cutting bridge, Detection Eye recognizes the exact position of the inserted sheet metal in a matter of seconds and supports the operator during the preparation for cutting.

Automatic Nozzle Changer

High process reliability and low preparation time – in just 15 seconds, the fiber laser changes nozzles based on the cutting plan. Less effort for more productivity.

HMI / Cutting Plan Editor

Copy, delete, rotate, move, and add – the editor makes it possible to adapt the existing cutting plan in just a few steps.

Machine Size

The right size for every material and application – you can get our machines in various sizes.

HMI / Cutting Plan Editor

As easy to operate as a smartphone. The intuitive HMI makes it easier to operate the machine, thereby increasing productivity

Automatic Nozzle Changer

High process reliability and low preparation time – in just 15 seconds, the fiber laser changes nozzles based on the cutting plan. Less effort for more productivity.

Detection Eye

More precision: Using a camera system on the cutting bridge, Detection Eye recognizes the exact position of the inserted sheet metal in a matter of seconds and supports the operator during the preparation for cutting.

Parameter Wizard

Use the Parameter Wizard to determine the optimum cutting parameters in a matter of minutes and achieve a lower cost per unit.

HMI / Cutting Plan Editor

The editor makes it possible to adapt the existing cutting plan in just a few steps.

Preparation for N2-Generator

Stay independent of gas suppliers – for a consistent gas supply and cutting quality.

Tilt Prevention

The software function prevents collisions with tipped parts and supports the automatic sorting process. The cutting plan is optimized to prevent tipping of cut parts.

Cut Control Fiber

The integrated sensor in the Cut Control Fiber makes it possible to interrupt the cutting process in case of cutting problems. Other functions make it possible to handle the material to be cut and the machine responsibly. These include process monitoring during cutting with nitrogen, monitoring the piercing process, or recognizing the exact position of the sheet edges.

Intelligent Cutting Process

Increase your productivity: The cutting process is stable thanks to comprehensive process monitoring.

NCT & KerfScan

Nozzle Control Tool (NCT) muliggør hurtig og sikker centrering af dyser samt overvågning af dysernes tilstand. KerfScan kontrollerer skæreprocessen under brændeskæring af stål, registrerer problemer og løser dem. Det giver en stabil proces, uden at operatøren er nødt til at gribe ind.

MixGas

With a mixture of nitrogen and oxygen, we combine the benefits of each cutting method. Example: You improve cutting quality when cutting thicker steel.

HP Shop Air

With this function, you achieve a lower cost per part and cut sheet thicknesses of 3 mm to 30 mm with compressed air.

Preparation for N2-Generator

Stay independent of gas suppliers – for a consistent gas supply and cutting quality.

High Laser Power

A high laser power increases productivity, improves cutting quality, and allows even thicker sheet metal to be machined economically. An essential component for high-power cutting is the right cutting head.

Intelligent Cutting Process

Increase your productivity: The cutting process is stable thanks to comprehensive process monitoring.

Cutting Head / Protective Glass

Precision & speed – using the Bystronic cutting head, you can machine thin and thick materials with the highest quality. The integrated changing system also allows fast maintenance of the protective glass.

MixGas

With a mixture of nitrogen and oxygen, we combine the benefits of each cutting method. Excellent cutting quality, as with pure oxygen, combined with the high cutting speeds of pure nitrogen.

Parameter Wizard

Use the Parameter Wizard to determine the optimum cutting parameters in a matter of minutes and achieve a lower cost per unit.

NCT & KerfScan

The Nozzle Control Tool (NCT) makes it possible to center nozzles quickly and reliably, as well as monitor the nozzle state. KerfScan checks the cutting process when flame cutting steel, detects problems, and solves them. This ensures a stable process without operator interaction.

BeamShaper

The manual or automatic BeamShaper in the cutting head helps when the material quality is poor. Improves cutting quality and increases process stability when cutting medium and thick mild steel.

ByPos Fiber

ByPos Fiber automatically sets the focus position according to the material and its thickness. The focus position is optimally matched to the process.

Spot Control

Depending on the sheet thickness and the material, Spot Control automatically adapts the focal point to it.

Detection Eye

More precision: Using a camera system on the cutting bridge, Detection Eye recognizes the exact position of the inserted sheet metal in a matter of seconds and supports the operator during the preparation for cutting.

Automatic Nozzle Changer

High process reliability and low preparation time – in just 15 seconds, the fiber laser changes nozzles based on the cutting plan. Less effort for more productivity.

HMI / Cutting Plan Editor

Copy, delete, rotate, move, and add – the editor makes it possible to adapt the existing cutting plan in just a few steps.

Machine Size

The right size for every material and application – you can get our machines in various sizes.

HMI / Cutting Plan Editor

As easy to operate as a smartphone. The intuitive HMI makes it easier to operate the machine, thereby increasing productivity

Automatic Nozzle Changer

High process reliability and low preparation time – in just 15 seconds, the fiber laser changes nozzles based on the cutting plan. Less effort for more productivity.

Detection Eye

More precision: Using a camera system on the cutting bridge, Detection Eye recognizes the exact position of the inserted sheet metal in a matter of seconds and supports the operator during the preparation for cutting.

Parameter Wizard

Use the Parameter Wizard to determine the optimum cutting parameters in a matter of minutes and achieve a lower cost per unit.

HMI / Cutting Plan Editor

The editor makes it possible to adapt the existing cutting plan in just a few steps.

Preparation for N2-Generator

Stay independent of gas suppliers – for a consistent gas supply and cutting quality.

Tilt Prevention

The software function prevents collisions with tipped parts and supports the automatic sorting process. The cutting plan is optimized to prevent tipping of cut parts.

Cut Control Fiber

The integrated sensor in the Cut Control Fiber makes it possible to interrupt the cutting process in case of cutting problems. Other functions make it possible to handle the material to be cut and the machine responsibly. These include process monitoring during cutting with nitrogen, monitoring the piercing process, or recognizing the exact position of the sheet edges.

Intelligent Cutting Process

Increase your productivity: The cutting process is stable thanks to comprehensive process monitoring.

NCT & KerfScan

Nozzle Control Tool (NCT) muliggør hurtig og sikker centrering af dyser samt overvågning af dysernes tilstand. KerfScan kontrollerer skæreprocessen under brændeskæring af stål, registrerer problemer og løser dem. Det giver en stabil proces, uden at operatøren er nødt til at gribe ind.

MixGas

With a mixture of nitrogen and oxygen, we combine the benefits of each cutting method. Example: You improve cutting quality when cutting thicker steel.

HP Shop Air

With this function, you achieve a lower cost per part and cut sheet thicknesses of 3 mm to 30 mm with compressed air.

Preparation for N2-Generator

Stay independent of gas suppliers – for a consistent gas supply and cutting quality.

Vores eksperter i laserskærere er klar til at hjælpe dig.

Videoer

Højdepunkterne fra videoen

Hurtig konfiguration

Med tilvalget «Parameter Wizard» finder du hurtigt de perfekte parametre til stål fra 4 til 15 mm med N2 og MixGas.

Bredt spektrum

Uanset om det drejer sig om blødt stål, rustfrit stål, aluminium eller ikke-jernholdige metaller er produktionsspektret bredt, og du kan bearbejde pladetykkelser (uden ikke-jernholdige metaller) på op til 50 mm.

Høj processikkerhed

Bystronics automatiseringsløsninger garanterer optimal udnyttelse og maksimal sikkerhed ved næsten ubemandet drift.

Enkel betjening

Via en berøringsskærm på 21,5" kan Bystronic-softwaren BySoft Cell Control Cut betjenes lige så let som en smartphone.

Kortvideo-tutorials

Bystronic-service Skræddersyet til dine behov og en gnidningsfri produktion

ByCare-pakke

Vores uddannede serviceeksperter sikrer effektive produktionsprocesser og værner om dine medarbejderes sikkerhed. Vi tilbyder vores tjenester som basispakker og totalløsninger afhængigt af behovet.

360° Customer Advisor

Vi analyserer din produktion og finder ud af, hvor dine styrker og svagheder ligger. På baggrund af dette kan du optimere processer og reducere nedetid.

Vores tjenesteydelser

Vi vedligeholder dine Bystronic-systemer og sætter dem i stand. Efter ønske fås opgraderinger til eftermontering eller tilbehør, som kan fintune dine maskiner. Når behovet opstår, foretager vi også gerne et hovedeftersyn.

Vores serviceeksperter er altid klar til at hjælpe dig – hurtigt og personligt

Softwaren BySoft Cell Control Cut: Enkel betjening af laserskæreren

Softwaren gør det let for dig at styre laserskæreren og den integrerede automatisering. Takket være den 21,5" store berøringsskærm er det lige så let som med en smartphone. Du skal ikke længere bruge tid på at finde de rigtige indstillinger. Store symboler, korte navigationsveje og hjælpefunktioner gør vores software så enestående.

Dermed har du tid til det vigtigste.