Modular Tool Changer Automatic tool change for press brakes

Accelerate set-up times Bend faster thanks to an automatic tool change

Don't waste any more time: Set-up takes up to 70% of the bending process. It is time consuming and physically demanding for large tools.

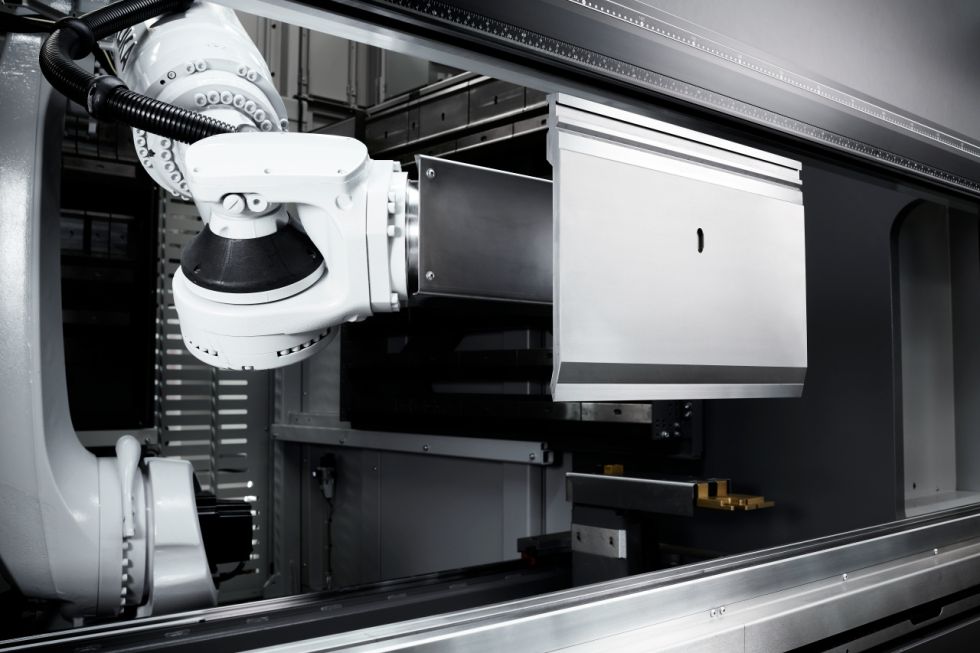

The Modular Tool Changer takes a load off your personnel and boosts your productivity. It changes tools on your Xpert Pro press brake fully automatically, thereby ensuring high-precision bending processes.

Protect your parts and tools Longer useful life for your tools

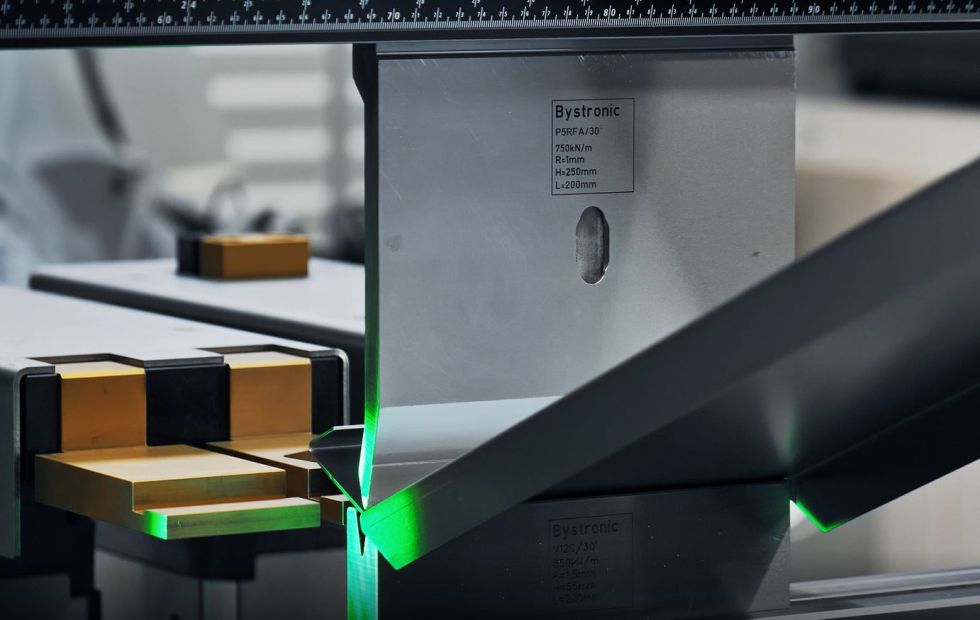

The automatic cleaning of the press brake guarantees that tools are positioned accurately and ensures even more precise bending processes. They can be used longer thanks to their gentle treatment.

Make use of all your room to maneuver Automatic tool change, even for large tools

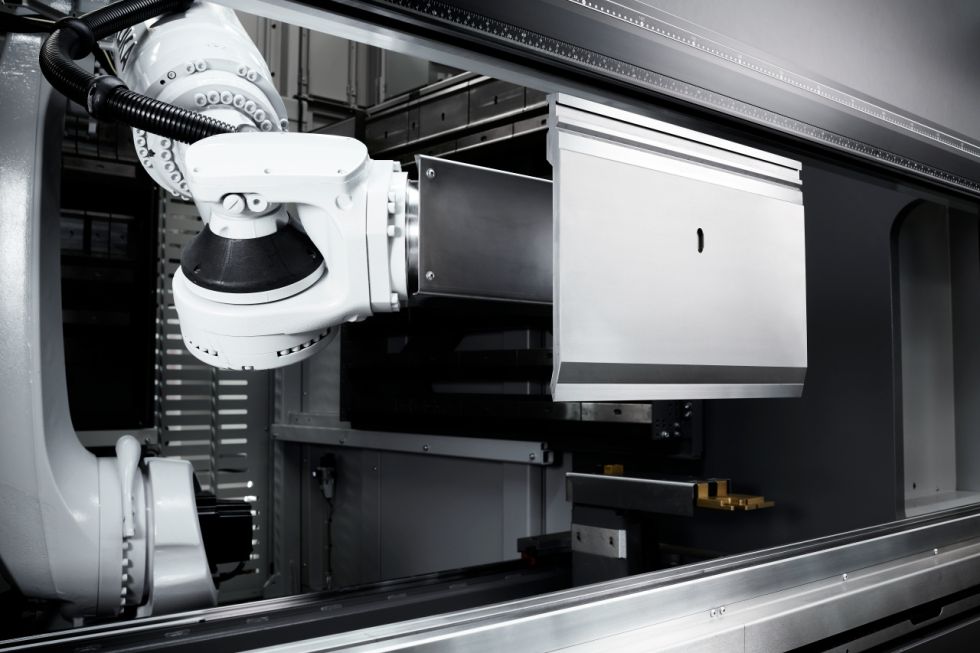

The 6-axis robot has a carrying capacity of 25 kilograms. It changes lower tools up to a size of V120 and upper tools up to 350 millimeters tall. If necessary, upper tools can be rotated by 180 degrees.

Intelligent software and sensors Integrate new tools at the push of a button

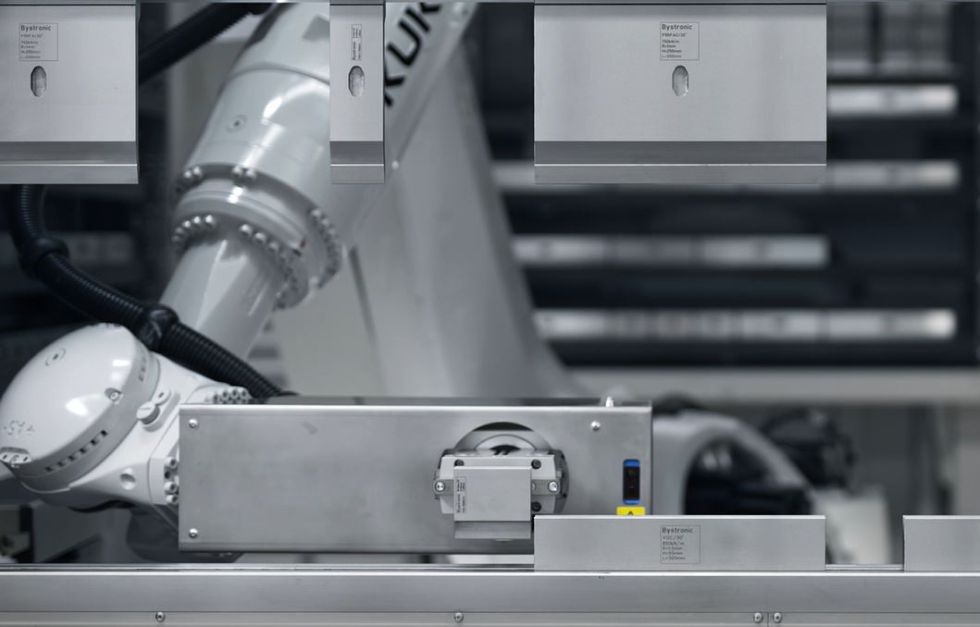

The Modular Tool Changer is linked to the bending software BySoft Cell Control Bend. The intelligent sensors detect new tools automatically and immediately integrate them into the magazine. This eliminates the need for any programming work.

Accelerate set-up times Bend faster thanks to an automatic tool change

Don't waste any more time: Set-up takes up to 70% of the bending process. It is time consuming and physically demanding for large tools.

The Modular Tool Changer takes a load off your personnel and boosts your productivity. It changes tools on your Xpert Pro press brake fully automatically, thereby ensuring high-precision bending processes.

Protect your parts and tools Longer useful life for your tools

The automatic cleaning of the press brake guarantees that tools are positioned accurately and ensures even more precise bending processes. They can be used longer thanks to their gentle treatment.

Make use of all your room to maneuver Automatic tool change, even for large tools

The 6-axis robot has a carrying capacity of 25 kilograms. It changes lower tools up to a size of V120 and upper tools up to 350 millimeters tall. If necessary, upper tools can be rotated by 180 degrees.

Intelligent software and sensors Integrate new tools at the push of a button

The Modular Tool Changer is linked to the bending software BySoft Cell Control Bend. The intelligent sensors detect new tools automatically and immediately integrate them into the magazine. This eliminates the need for any programming work.

Minimize set-up times and increase bending quality with our Modular Tool Changer.

Technical specifications All information on the Modular Tool Changer

| Modular Tool Changer | |

| Tonnage | 100 – 320 t |

| Bending length | 3100 – 4300 mm |

| Standard stroke | 450 mm |

| Open height | 840 mm |

| Throat | 400 mm |

| Table Width | 74/110 mm |

| Max. tool capacity tool magazine | 52 m |

| Max. length upper tool | 515 mm |

| Max. height upper tool | 350 mm |

| Max. bottom tool opening | 120 mm |

Videos Modular Tool Changer

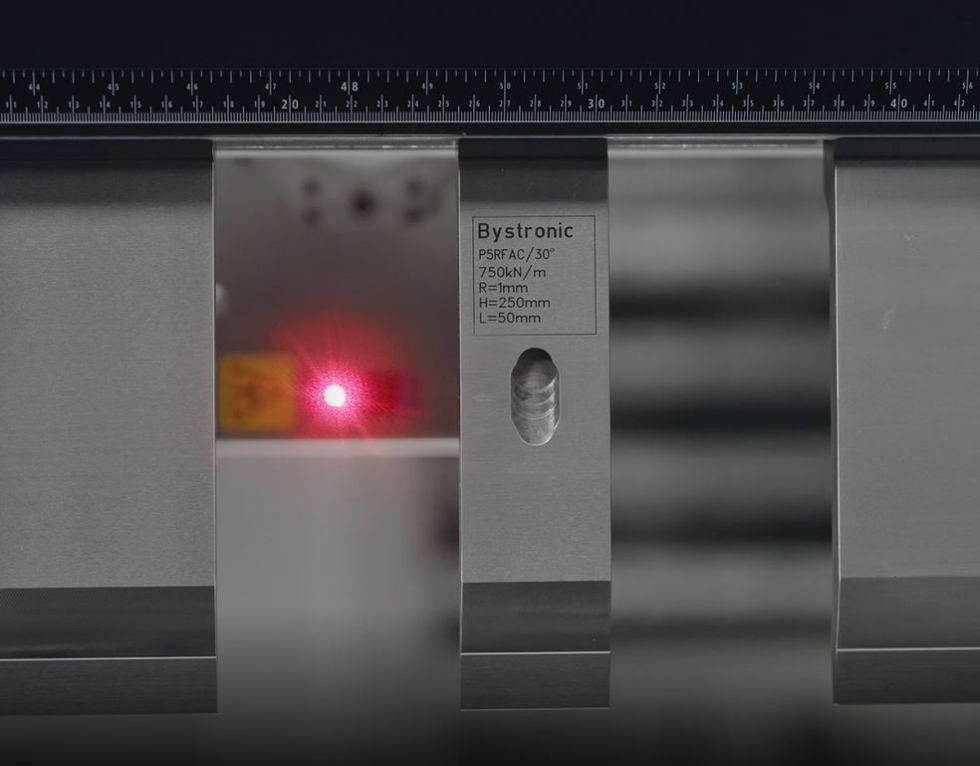

Save time and increase bending quality using the automatic tool change. Tool sets are positioned precisely and without wear in the clamping system of the upper and lower beams. The automatic rotation of the upper tools increases the variety of bending applications. The modular design makes retrofitting possible for press brakes in the Xpert Pro series.

Highlights from the video

Higher productivity

The automatic tool changer can be easily retrofitted to any Xpert Pro press brake and significantly reduces set-up times.

Maximum precision

Automatic cleaning of the bending table guarantees that tools are positioned accurately and that the bending process is highly precise.

Minimum wear

The tools are handled gently and are always neatly stowed in the magazine. This reduces wear and allows them to be used longer.

No programming work needed

The intelligent sensors detect new tools automatically and immediately integrate them into the magazine.

We are happy to advise you on automatic tool change for your press brake.

Bystronic Service Tailor-made for your needs and smooth production

ByCare packages

Our trained service experts ensure efficient production processes and safety for your employees. Depending on the requirements, we offer packages with basic to all-around services.

360° Customer Advisor

We analyze your production and determine your strengths and weaknesses. Based on this information, you can optimize processes and decrease downtime.

Our services

We maintain and repair your Bystronic systems. Optionally, you can obtain upgrades to retrofit your system or accessories to fine-tune your solution. Upon request, we can also perform a general overhaul.

Our service experts are always there for you – quickly and in person

Software BySoft Cell Control Bend: The software for your press brake

The Modular Tool Changer is connected to the bending software. Together with the sensors of the tool changer, it automatically detects and integrates the tools. You can therefore use BySoft Cell Control Bend to control all process steps with ease.