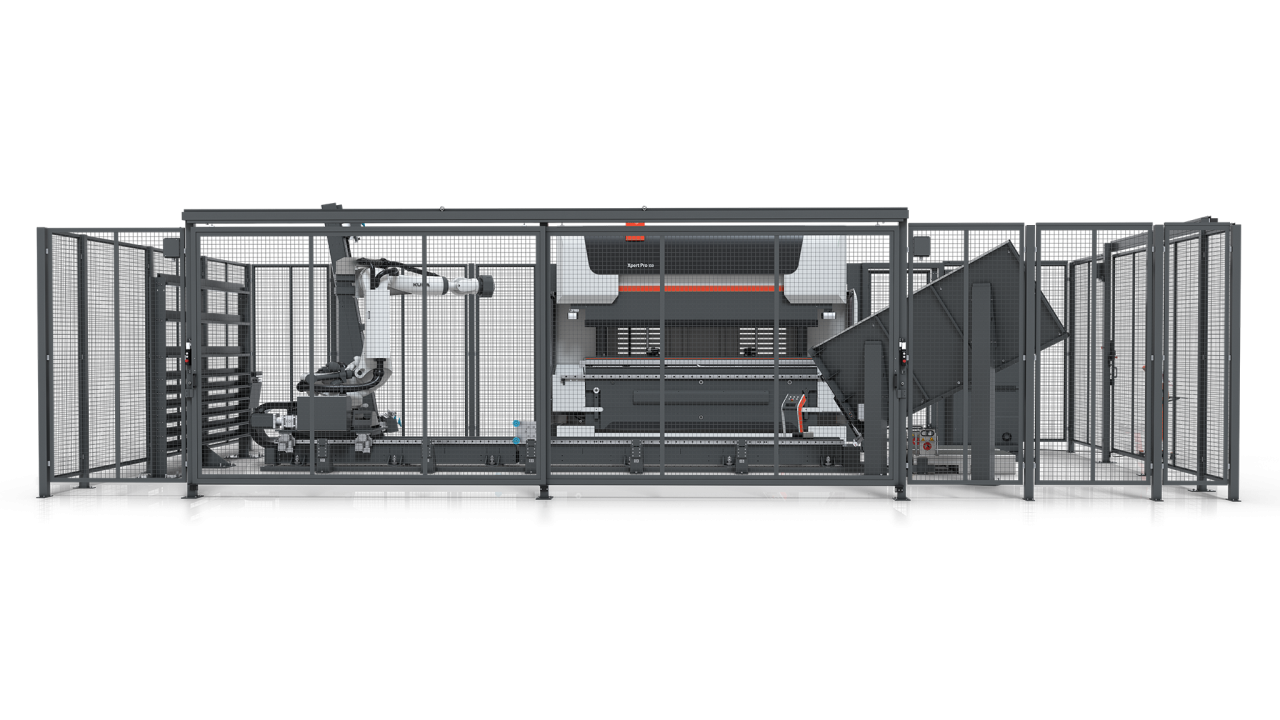

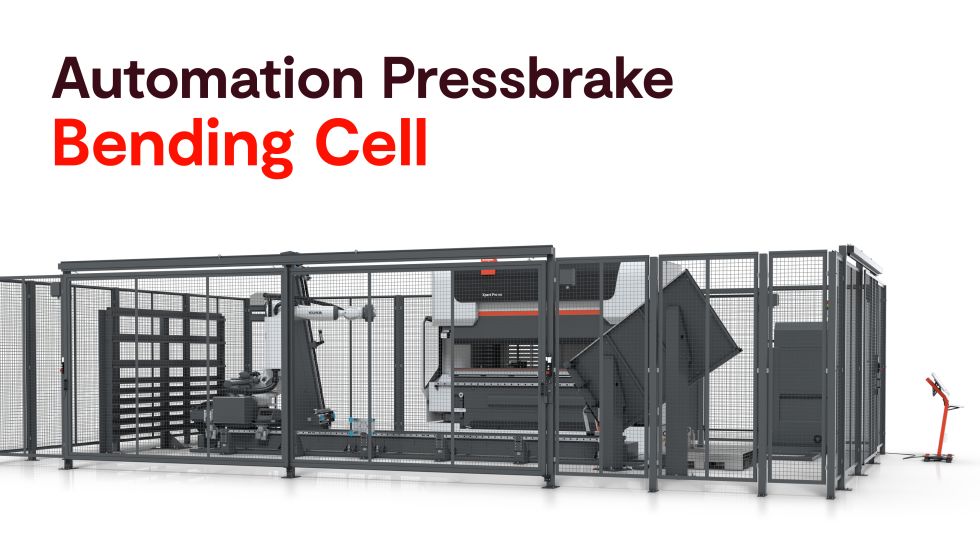

Bending Cell The all-round worry-free automatic sheet metal bending machine

Work autonomously Fully automatic bending – 24/7

With our automatic sheet metal bending machine, your production runs at full speed: In a team with an agile robot, our high-end Xpert Pro press brake works completely autonomously.

- The robot and press brake can be controlled intuitively and conveniently via the touchscreen.

- The intelligent BySoft Cell Control Bend software independently creates optimal bending sequences.

The software also determines the appropriate tools for each job list.

Professional automatic sheet metal bending machine Save 30 % time in your bending processes

The automatic sheet metal bending machine operates faster than the most experienced bending professional. The fully automatic tool and gripper changer eliminates the need for manual intervention. This alone results in time savings of up to 30% during set-up.

Stay flexible – no matter what comes your way Autonomous, even with changing order situations

Automation solutions are often too rigid for changing orders. This isn't the case with the Bending Cell: The 7-axis robot offers maximum flexibility for a wide variety of tasks. Even night shifts with varying work are a breeze for the automatic sheet metal bending machine.

Proven and patented Trust in constant quality

Maximum precision is guaranteed with the proven technology of our Xpert Pro flagship. Dynamic crowning and our patented Pressure-Reference technology ensure constant quality from the first part to the last.

Benefit from maximum flexibility and quality with our autonomous automatic sheet metal bending machine.

Technical specifications All information on the Bending Cell

| Bending Cell | |

| Tonnage Abkantpresse | 100, 150, 200, 250, 320 t |

| Bending length | 3100 + 4300 mm |

| Max. part size | 3000 × 1500 mm |

| Max. part weight | ca. 130 kg |

| Max. Robot Payload | 300 kg |

| Min. sheet thickness | 0.5 mm |

| Air supply | 6 – 8 bar |

| Max. plate stack | ca. 1500 mm |

| Max. sheet metal stack height | ca. 2000 mm |

| Max. tool capacity in the magazine | 37 m |

| Number of gripper stations | 5 + |

Videos Bending Cell

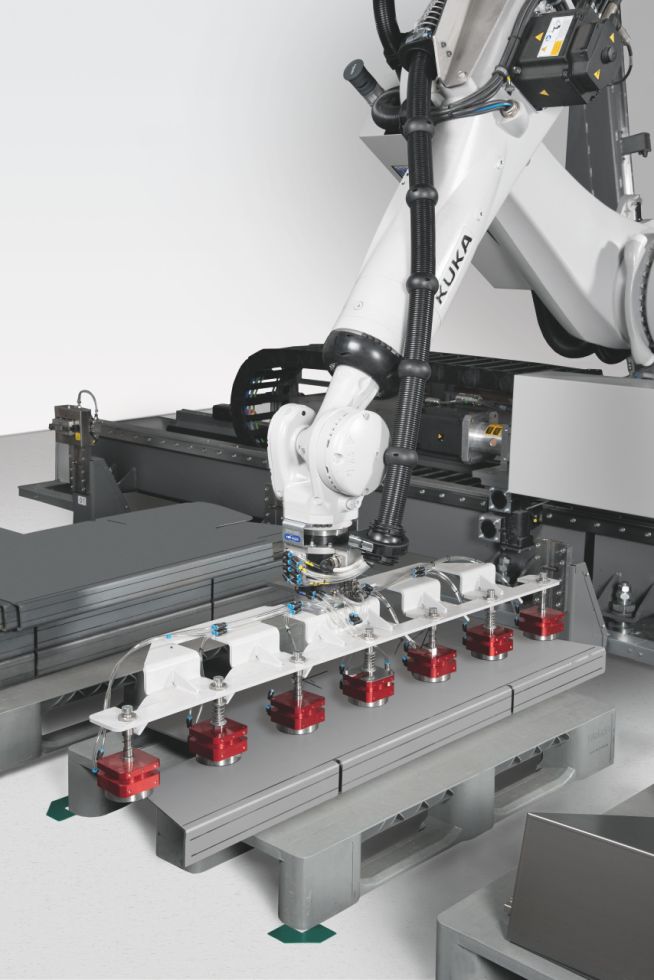

Save time and produce bent parts precisely and without personnel. Our 7-axis robot with a high carrying capacity completes bending orders fully automatically and without errors, even for heavy components.

The highlights include the following:

- Automatic double sheet check

- Automatic gripper and tool change and regrip station

- Fully automatic reading in of new tools, and much more

Highlights from the video

High availability thanks to its modular design

Depending on how it is equipped, the automatic sheet metal bending machine provides a bending length of up to 4 meters, a generous material store, and a tool magazine.

Maximum flexibility

Whether it's for small batch sizes or large series – the 7-axis robot works reliably with a wide variety of orders.

Broad power spectrum

Choose from five power levels. If necessary, the press capacity reaches from 100 to 320 tons, and the robot carrying capacity covers a spectrum of 90 to 270 kilograms.

Consistent bend accuracy

The proven technology of the high-end Xpert Pro press brake guarantees maximum precision from the first part to the last.

Do you have questions about our automatic sheet metal bending machine? We are happy to advise you!

Bystronic Service Tailor-made for your needs and smooth production

ByCare packages

Our trained service experts ensure efficient production processes and safety for your employees. Depending on the requirements, we offer packages with basic to all-around services.

360° Customer Advisor

We analyze your production and determine your strengths and weaknesses. Based on this information, you can optimize processes and decrease downtime.

Our services

We maintain and repair your Bystronic systems. Optionally, you can obtain upgrades to retrofit your system or accessories to fine-tune your solution. Upon request, we can also perform a general overhaul.

Our service experts are always there for you – quickly and in person

Software for your automatic sheet metal bending machine BySoft Cell Control Bend: Fully automatic, unmanned production

The Bending Cell is connected to the bending software. This facilitates automatic control of all process steps for your automatic sheet metal bending. Your advantages are:

- Production can be monitored at all times on mobile end devices.

- Bending orders can be conveniently programmed offline.

- The data is then imported into BySoft Cell Control Bend, without interrupting current production.

Software for more efficient processes BySoft Suite for networked production

The future of sheet processing lies in intelligent production. Bystronic software digitalizes and connects your entire company to optimally control your production.

In order to master these challenges, Bystronic has developed a trend-setting software. It enables your company to optimally control your production and your automatic sheet metal bending machine. All areas in the company are digitalized and linked by the software. It ensures seamless communication and efficient control of production.

Let Bystronic guide you into the digital future of sheet metal processing.