Your best choice for sheet metal processing

-

Laser Cutting -

Laser Automation -

Press Brakes -

Bending Automation -

Tube Laser Cutting -

Software

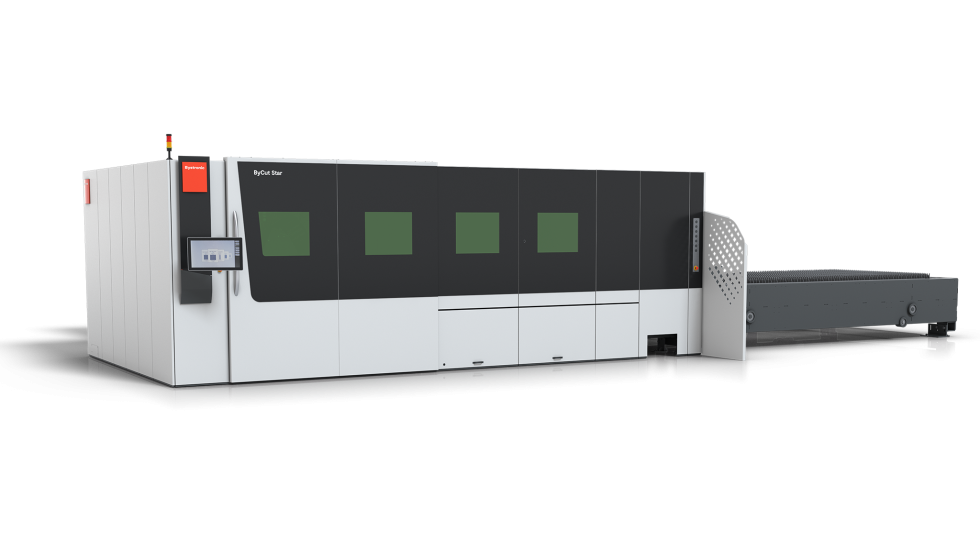

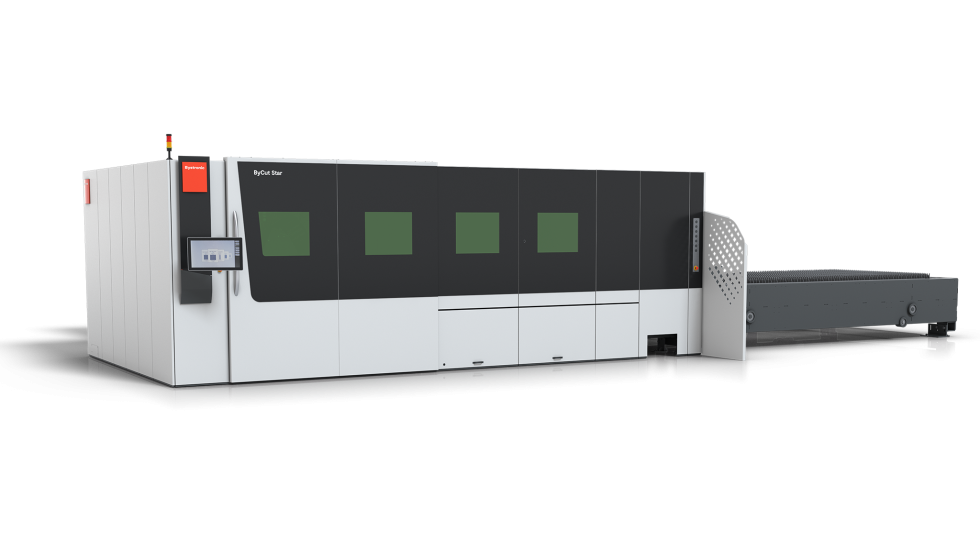

Your best choice for Laser Cutting

Fast, flexible, and precise: Smart machines for laser cutting

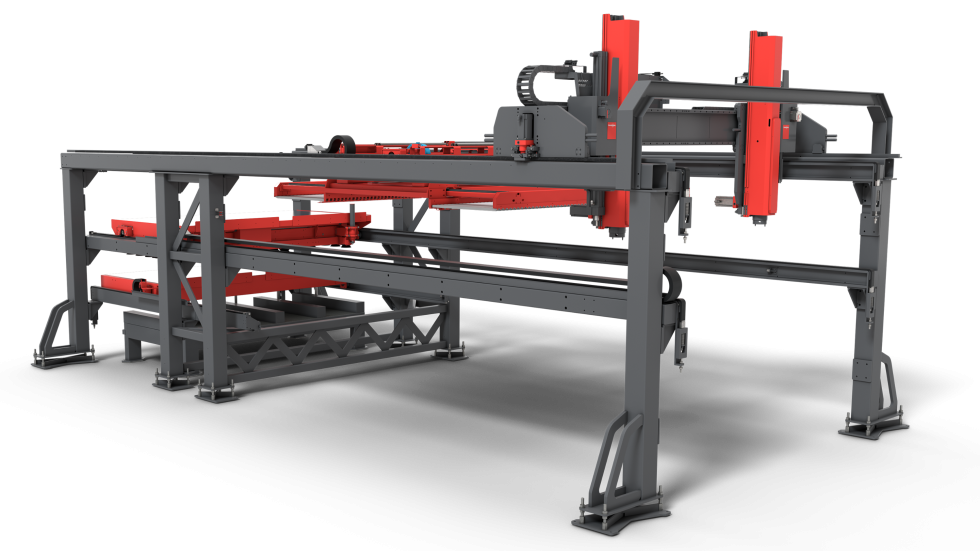

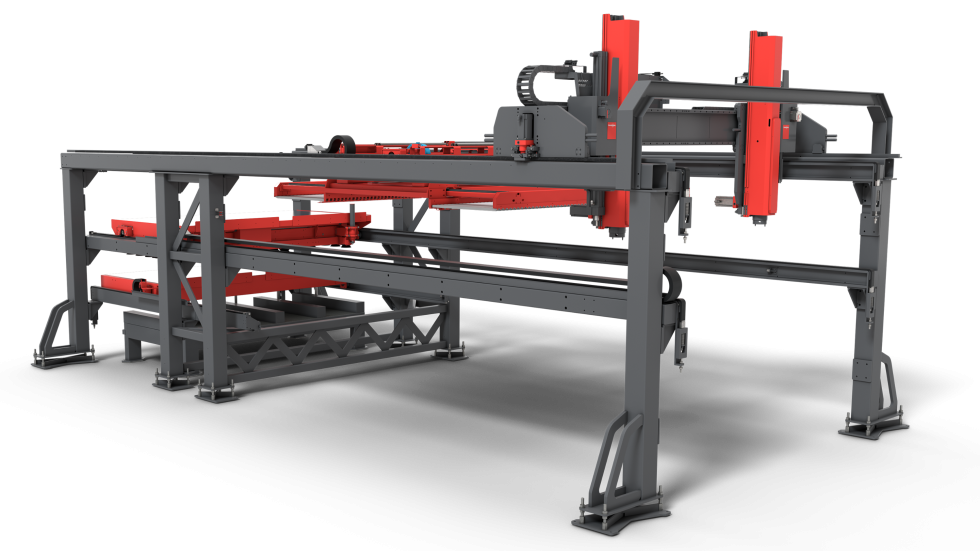

Your best choice for Laser Automation

Productivity & efficiency: Optimize your laser cutting system with laser automation

Your best choice for Press Brakes

Smart, intuitively operable, and strong: Press brakes for any need

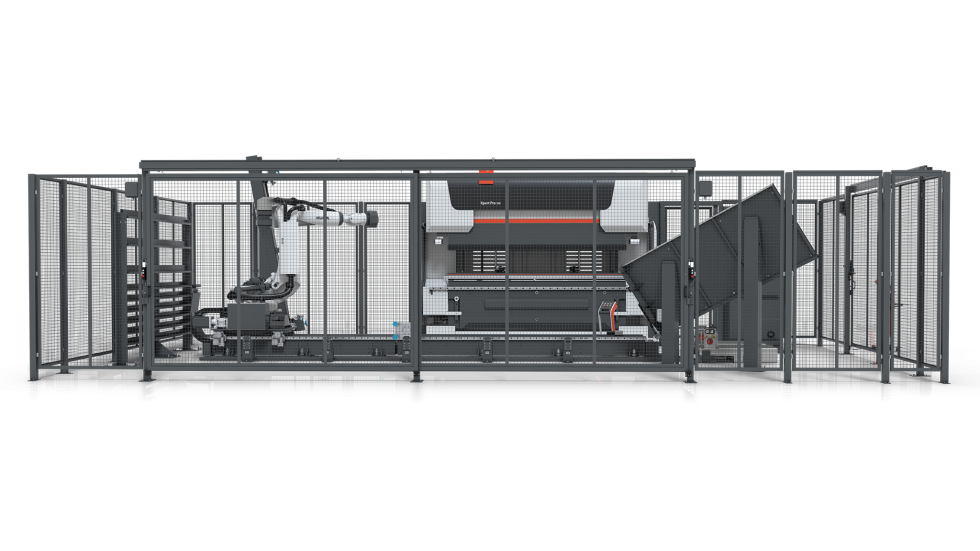

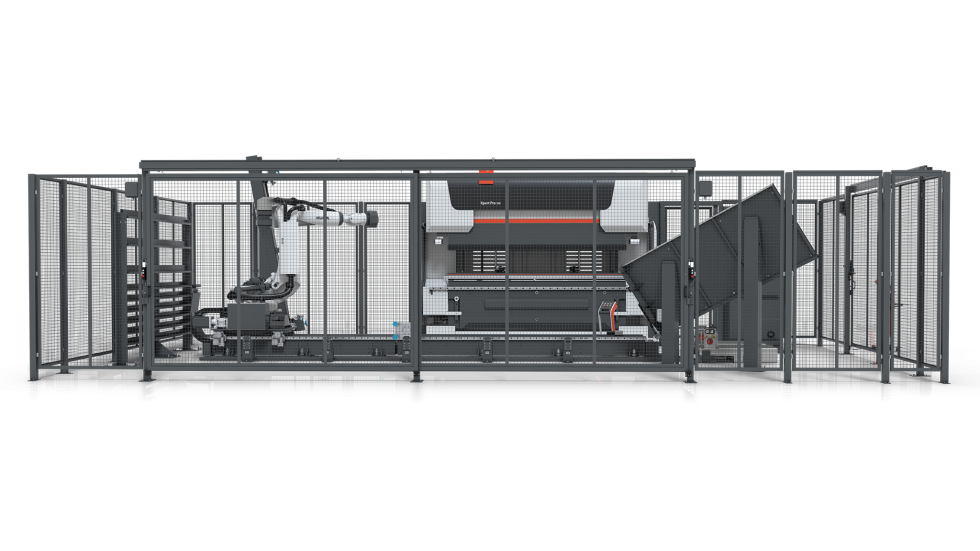

Your best choice for Bending Automation

Productivity & efficiency: Optimize your press brakes

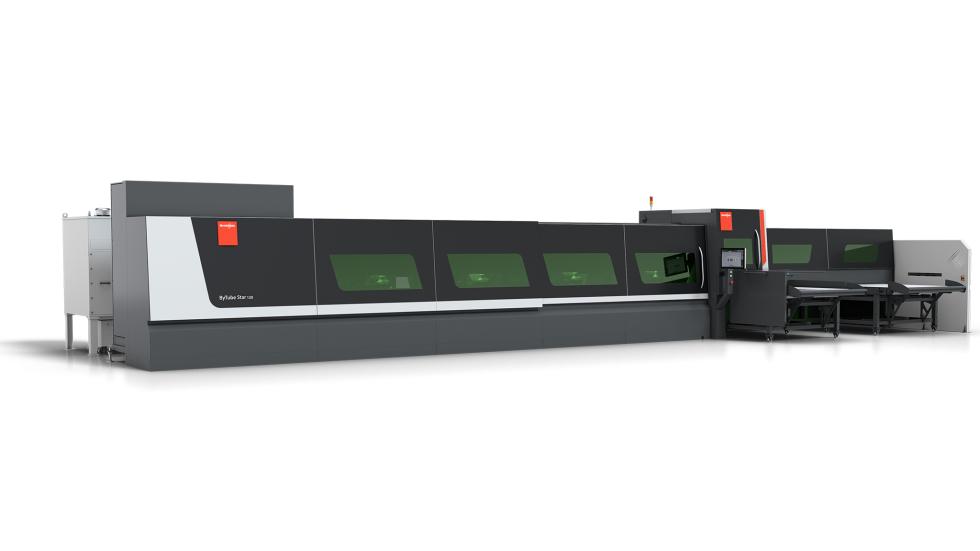

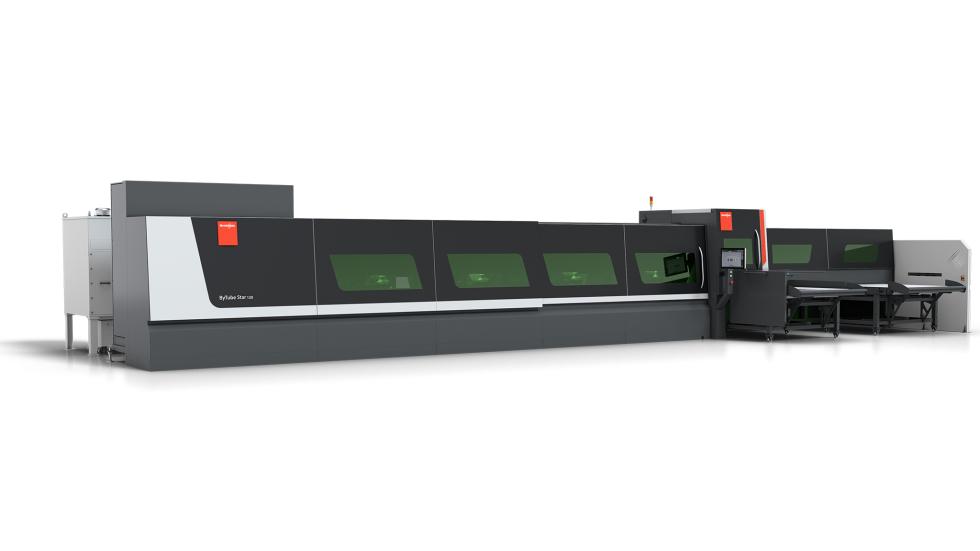

Your best choice for Tube Laser Cutting

Flexible, powerful, and fast: More efficient cutting processes for greater profit

Your best choice for Software

The Software to enable the digitalization at sheet metal companies

Your best choice for Laser Cutting

Fast, flexible, and precise: Smart machines for laser cutting

Your best choice for Laser Automation

Productivity & efficiency: Optimize your laser cutting system with laser automation

Your best choice for Press Brakes

Smart, intuitively operable, and strong: Press brakes for any need

Your best choice for Bending Automation

Productivity & efficiency: Optimize your press brakes

Your best choice for Tube Laser Cutting

Flexible, powerful, and fast: More efficient cutting processes for greater profit

Your best choice for Software

The Software to enable the digitalization at sheet metal companies

Working for Bystronic Would you like to become part of our team?

We live our company values:

- Innovation: We are constantly working on new solutions with added value for our customers.

- Openness: Here, everyone is involved, because we communicate openly with one another.

- Commitment: At Bystronic, we support each other.

Use Bystronic as your stepping stone into the international professional world. From training and internship to newcomers and professionals – Bystronic offers you the right environment for your career.

Your best choice for sheet metal processing of the future

At Bystronic, our specialists are happy to help you